Garbage dehydrator capable of recycling heat energy

A garbage dehydration and thermal energy technology, which is applied in dryers, lighting and heating equipment, local agitation dryers, etc., can solve the problems of reducing garbage combustion efficiency, energy waste, and non-recycling of heat, so as to improve the utilization rate of thermal energy, The effect of increasing residence time and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

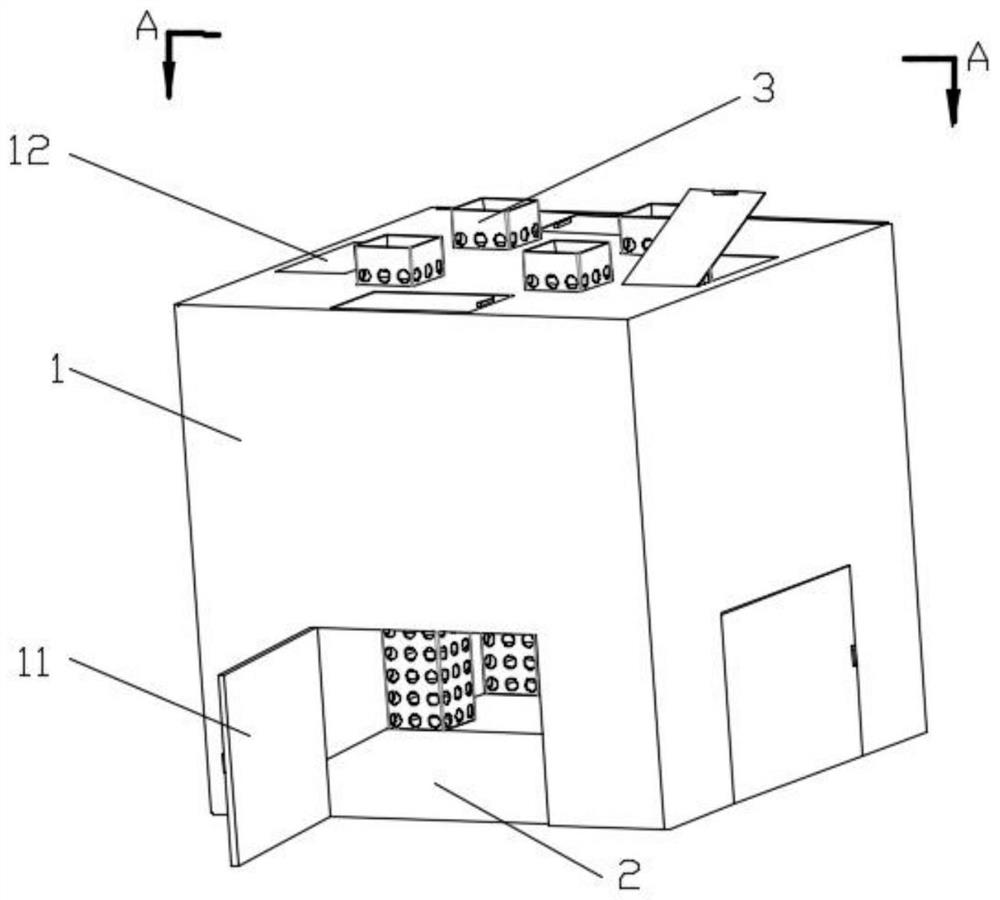

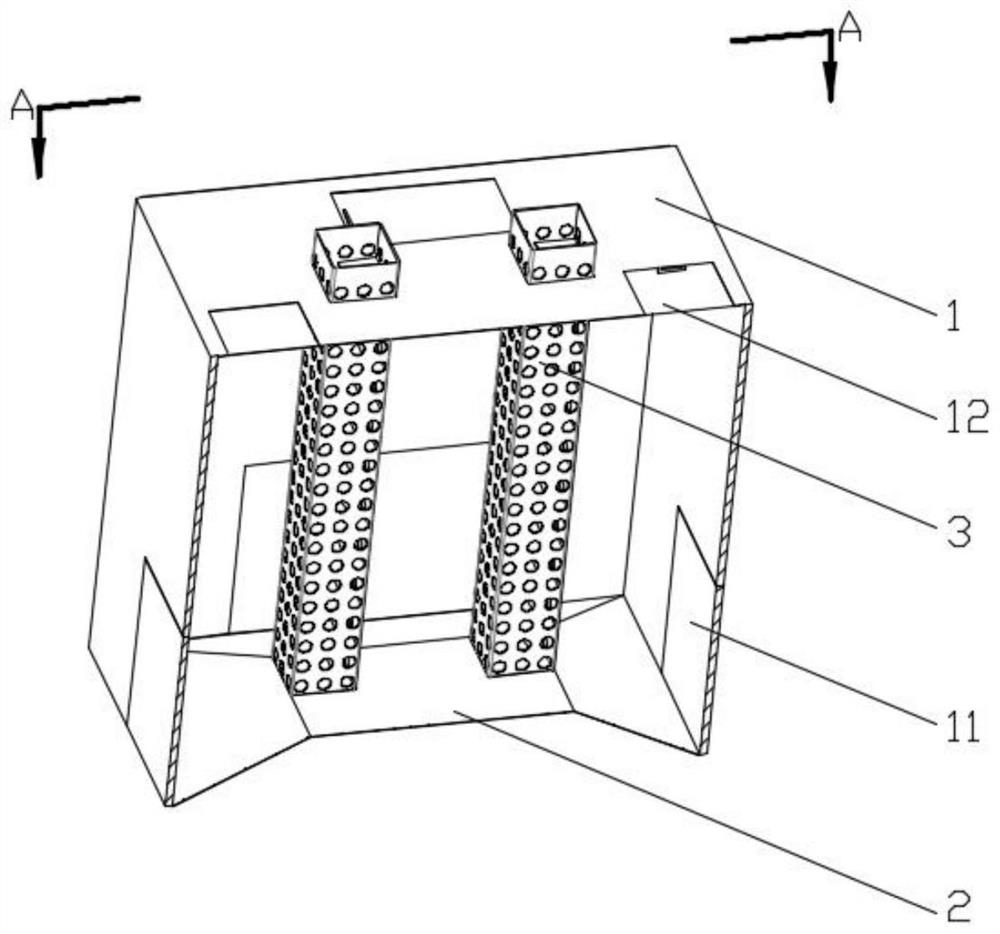

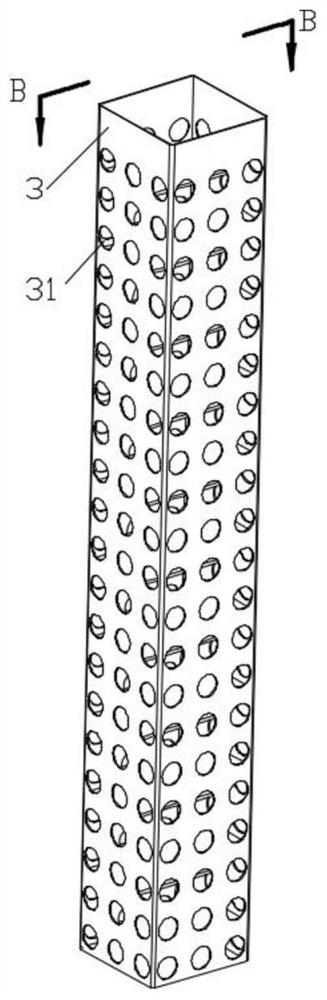

[0023] refer to Figure 1-4 A thermal energy recycling garbage dehydrator shown includes: a housing 1, a deflector 2 and four air guide cylinders 3, wherein the deflector 2 is arranged at the bottom of the housing 1, and the deflector 2 is provided with There is a smoke inlet 21. Four air guiding cylinders 3 are all arranged inside the housing 1, and the top of each air guiding cylinder 3 runs through the top of the housing 1, and the bottom end of each air guiding cylinder 3 is respectively connected to a smoke opening 21 Corresponding settings.

[0024] The side walls around the housing 1 are respectively provided with a discharge door 11, and each discharge door 11 is close to the deflector 2, and the position of the discharge door 11 is lower to facilitate the discharge of dried articles. The top of the casing 1 is provided with four feed doors 12, and each feed door 12 is set corresponding to a discharge door 11 respectively, and a certain distance is kept between the fo...

Embodiment 2

[0028] refer to Figure 1-7 Shown is a thermal energy recycling garbage dehydrator, a housing 1, a deflector 2 and four air guide cylinders 3, wherein the deflector 2 is a four-pyramid frustum deflector casing, and the four-pyramid frustum deflector casing is arranged on the casing 1, and the top of the truncated pyramid guide shell is provided with four smoke inlets 21 in an array. The four air guide tubes 3 are all arranged inside the shell 1, and the top of each air guide tube 3 runs through the shell 1, and the bottom end of each air guiding tube 3 is set correspondingly to a smoke port 21 respectively.

[0029] The side walls around the casing 1 are respectively provided with a discharge door 11, and each discharge door 11 is adjacent to the deflector 2; the top of the casing 1 is provided with 4 feed doors 12, and each feed door 12 Corresponding to a discharge gate 11 respectively.

[0030] In this embodiment, the four air guiding cylinders 3 are kept at a certain dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com