Novel efficient solar heat collecting tube

A solar heat collecting tube, high-efficiency technology, applied in the field of solar heat collecting tubes, can solve the problems of high manufacturing cost, small heating area, high cost, etc., and achieve the effects of high cost, improved start-up speed, and high absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

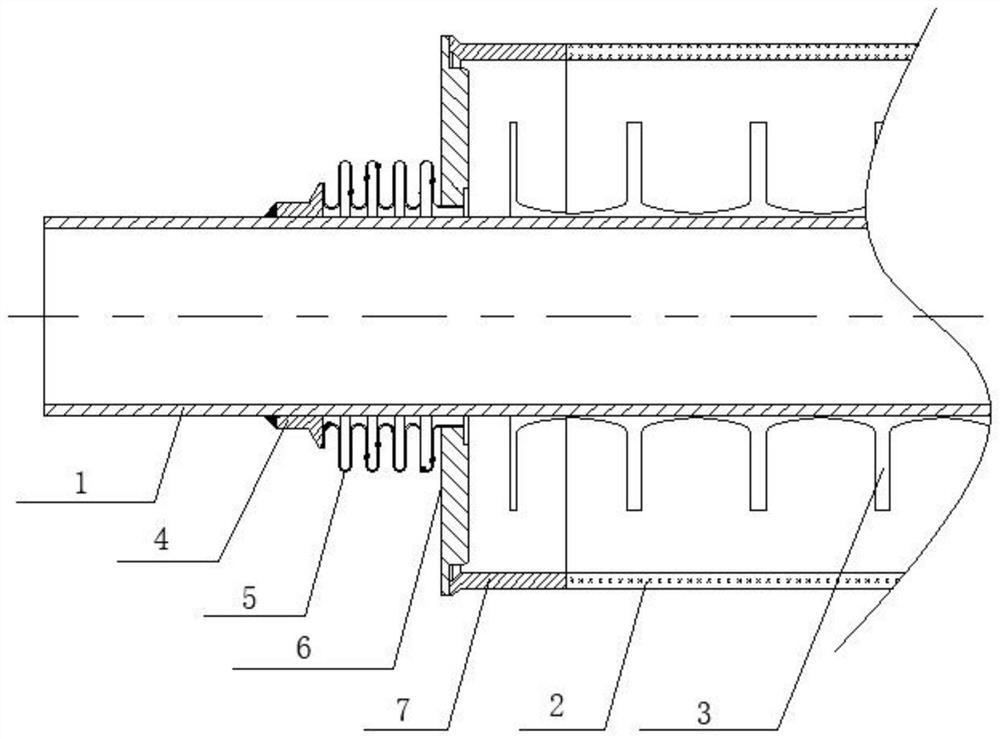

[0033] A new type of high-efficiency solar heat collection tube, including an inner stainless steel tube 1 and an outer glass tube 2 coaxially sleeved, the two ends of the inner stainless steel tube 1 and the outer glass tube 2 are sealed and connected by a seal, and the outer wall of the inner stainless steel tube 1 is provided with copper wings Flat plate 3, copper wing flat plate 3 is TU1 copper strip; wherein, the seal includes connecting pipe 4, expansion compensation bellows 5, kovar connector 6, and kovar 7.

[0034] The connecting pipe is fixedly connected with the expansion compensation bellows, and is welded to the outer wall of the inner stainless steel pipe at the end side of the connecting pipe. Dynamic balance, stronger application stability, wider temperature resistance and application temperature range, efficient and practical.

[0035] Among them, the thickness of the copper wing plate is 1% of the outer diameter of the inner stainless steel pipe, and the expa...

Embodiment 2

[0038] For the novel high-efficiency solar collector tube proposed in the embodiment, the preparation steps of the solar collector tube are as follows:

[0039] S1. Take the pre-treated stainless steel pipe and TU1 copper strip, press the TU1 thin strip tightly on the stainless steel pipe with a self-locking roller mold, and clean the coating, connect the two ends with connecting pipes and expansion compensation bellows, and The expansion compensation bellows has a built-in non-evaporable getter, and the inner stainless steel tube;

[0040] S2. Install the inner stainless steel tube in the outer glass tube through the kovar connector and kovar, and vacuumize the space between the inner stainless steel tube and the outer glass tube to form a vacuum cavity, that is, produce a high-vacuum solar heat collection tube.

[0041] Further, the outer glass tube has a double-layer structure, and the interlayer is evacuated to form a vacuum chamber.

[0042] Moreover, the wall surface in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com