Polyelectrolyte grafted polyvinyl alcohol spinning membrane for oil-water emulsion separation as well as preparation method and application of polyelectrolyte grafted polyvinyl alcohol spinning membrane

A polyvinyl alcohol spinning and polyelectrolyte technology, which is applied in separation methods, liquid separation, immiscible liquid separation, etc. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

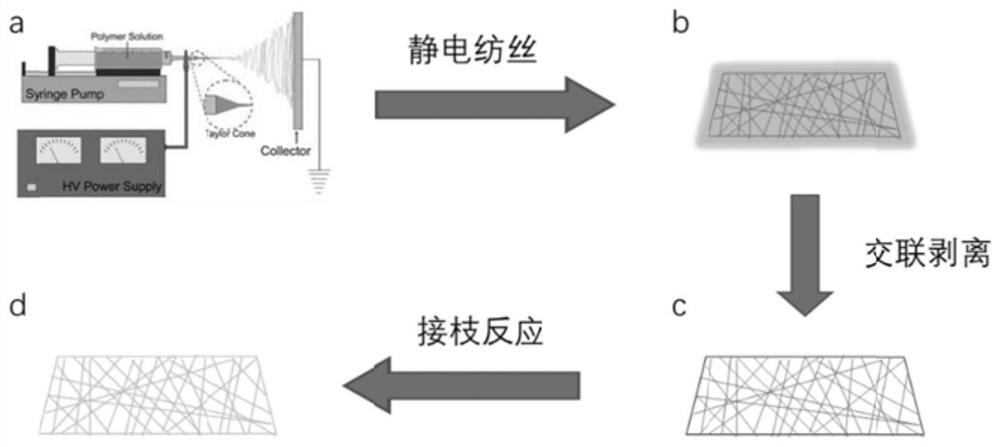

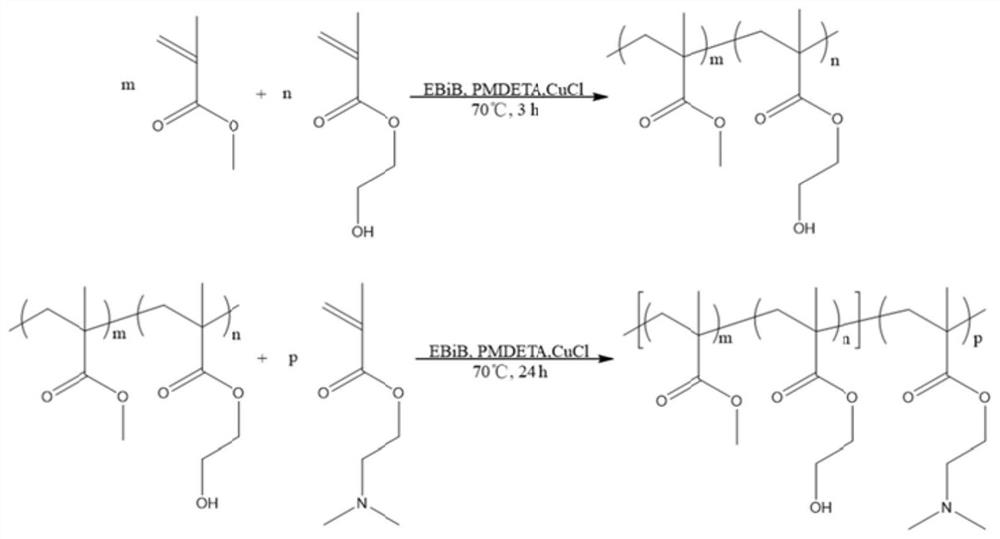

[0030] A kind of preparation method of the polyelectrolyte graft polyvinyl alcohol spinning membrane that the present invention is used for oil-water emulsion separation comprises the following steps:

[0031] Step 1: Polyvinyl alcohol (PVA) and sodium lauryl sulfate are dissolved in water together to form a colorless and transparent solution;

[0032] Preferably, the concentration of polyvinyl alcohol is 50 mg / ml-150 mg / ml, and the concentration of sodium lauryl sulfate is 5 g / L-15 g / L.

[0033] Step 2: Use an electrospinning apparatus to perform electrospinning operation on the colorless transparent solution formed in step 1 at a certain spinning injection speed, use a drum wrapped in aluminum foil at the receiving end, and spin for a certain period of time to form a Polyvinyl alcohol spun film of aluminum foil;

[0034] Preferably, the spinning bolus speed is 40 mg / h-60 mg / h based on the mass of polyvinyl alcohol, and the spinning time is 2 h-4 h.

[0035] Step 3: Dissolv...

Embodiment 1

[0042] A preparation method for a polyelectrolyte grafted polyvinyl alcohol spinning membrane for oil-water emulsion separation, comprising the following steps:

[0043] Step 1: Dissolving polyvinyl alcohol and sodium lauryl sulfate in water together to form a colorless and transparent solution;

[0044] Wherein, the concentration of polyvinyl alcohol is 100 mg / ml, and the concentration of sodium lauryl sulfate is 7 g / L.

[0045] Step 2: Use an electrospinning apparatus to perform electrospinning operation on the solution formed in step 1. The spinning bolus speed is 60 mg / h based on the mass of polyvinyl alcohol. The receiving end uses a drum wrapped in aluminum foil, and the spinning operation is 3 hours. Form a polyvinyl alcohol spun film with an aluminum foil, such as figure 1 a, as shown in 1b;

[0046] Step 3: Dissolve glutaraldehyde in acetone, add concentrated hydrochloric acid, immerse the polyvinyl alcohol spinning film with aluminum foil in it for 5 minutes, the p...

Embodiment 2

[0054] A preparation method for a polyelectrolyte grafted polyvinyl alcohol spinning membrane for oil-water emulsion separation, comprising the following steps:

[0055] Step 1: Dissolving polyvinyl alcohol and sodium lauryl sulfate in water together to form a colorless and transparent solution;

[0056] Wherein, the concentration of polyvinyl alcohol is 120 mg / ml, and the concentration of sodium lauryl sulfate is 5 g / L.

[0057] Step 2: Use an electrospinning apparatus to perform electrospinning operation on the solution formed in step 1. The spinning bolus speed is 55 mg / h based on the mass of polyvinyl alcohol. The receiving end uses a drum wrapped in aluminum foil, and the spinning operation is 4 hours. Forming polyvinyl alcohol spun film with aluminum foil;

[0058] Step 3: Dissolve glutaraldehyde in acetone, and add concentrated hydrochloric acid. Immerse the polyvinyl alcohol spun film with aluminum foil in it for 15 minutes, the polyvinyl alcohol spun film falls off ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com