Preparation method of special peptone for fermentation production of pullulan and product thereof

A pullulan polysaccharide and peptone technology, which is applied in the field of preparation of peptone for fermented pullulan polysaccharide, can solve the problems of low production level, low yield, and restrictions on the wide application of pullulan polysaccharide, so as to improve capacity and promote The effect of rapid growth and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

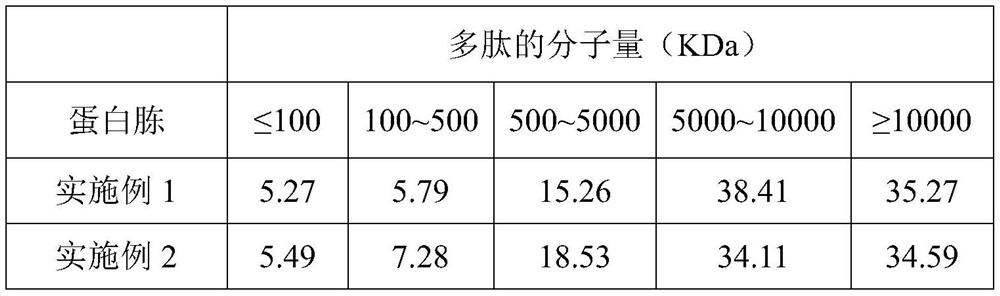

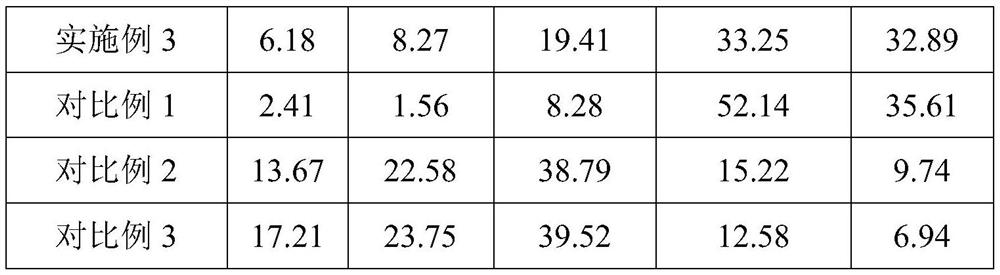

Embodiment 1

[0025] A preparation method for fermenting and producing pullulan special-purpose peptone:

[0026] (1) After mixing fresh fish bones and water at a mass ratio of 1:6, keep warm for 1 hour at a pressure of 3 standard atmospheres, press the bone broth into the storage tank (the tank's own pressure), and use the oil-water separator Separate the oil layer in the bone broth to obtain fish bone broth; add the fish bone broth to the enzymolysis tank, adjust the pH value to 7.2, and the temperature is 50°C, then add trypsin, aminopeptidase and neutral protease (trypsin, ammonia The amount of peptidase and neutral protease is respectively 0.2%, 0.2% and 0.1% of fresh fish bone quality), stirring slowly, stirring for 10 minutes and stopping for 5 minutes, stirring for 10 minutes and stopping for 5 minutes, stirring for 10 minutes and stopping for 10 minutes, stirring for 10 minutes and stopping for 10 minutes, stirring for 10 minutes Stop for 25 minutes, stir for 10 minutes and stop fo...

Embodiment 2

[0031] (1) After mixing fresh fish bones and water at a mass ratio of 1:6, keep warm for 1 hour at a pressure of 3 standard atmospheres, press the bone broth into the storage tank (the tank's own pressure), and use the oil-water separator Separate the oil layer in the bone broth to obtain fish bone broth; add the fish bone broth to the enzymolysis tank, adjust the pH value to 7, and the temperature is 48°C, then add trypsin, aminopeptidase and neutral protease (trypsin, ammonia The consumption of peptidase and neutral protease is respectively 0.3%, 0.3% and 0.15% of the fresh fish bone mass), stirring slowly, stirring for 10 minutes and stopping for 5 minutes, stirring for 10 minutes and stopping for 5 minutes, stirring for 10 minutes and stopping for 10 minutes, stirring for 10 minutes and stopping for 10 minutes, stirring for 10 minutes Stop for 15 minutes, stir for 10 minutes and stop for 25 minutes. After enzymolysis, add acetic acid (the amount of acetic acid is 0.1% of th...

Embodiment 3

[0036] (1) After mixing fresh fish bones and water at a mass ratio of 1:6, keep warm for 1 hour at a pressure of 3 standard atmospheres, press the bone broth into the storage tank (the tank's own pressure), and use the oil-water separator Separate the oil layer in the bone broth to obtain fish bone broth; add the fish bone broth to the enzymolysis tank, adjust the pH value to 7.5, and the temperature is 52°C, then add trypsin, aminopeptidase and neutral protease (trypsin, ammonia The amount of peptidase and neutral protease is respectively 0.1%, 0.1% and 0.05% of the fresh fish bone quality), stirring slowly, stirring for 10 minutes and stopping for 5 minutes, stirring for 10 minutes and stopping for 5 minutes, stirring for 10 minutes and stopping for 10 minutes, stirring for 10 minutes and stopping for 20 minutes, stirring for 10 minutes Stop for 25 minutes, stir for 10 minutes and stop for 25 minutes. After enzymolysis, add acetic acid (the amount of acetic acid is 0.1% of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com