Method for improving flash evaporation effect of C5 petroleum resin

A carbon five petroleum resin and flash evaporation technology, which is applied in the field of improving the flash evaporation effect of carbon five petroleum resin, can solve problems such as large hue, low softening point, and low viscosity of resin liquid, so as to save energy, improve flash evaporation effect, and improve quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

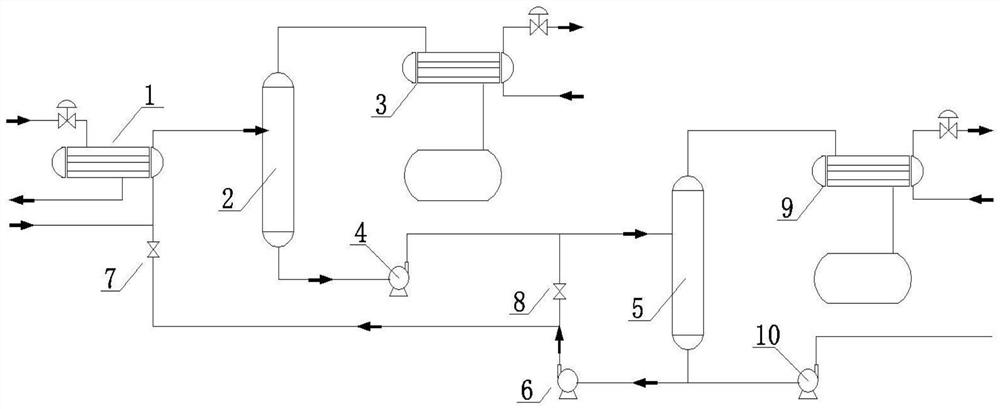

[0028] 1) The C5 petroleum resin polymer liquid that has been flashed once enters the feed preheater 1 to be heated, and the feed flow rate is 7m 3 / h, the shell side medium is steam with a pressure ≥ 4.0MPa, and the heating temperature is 250°C. The heated resin polymerization liquid enters the second flash tower 2 for flash evaporation, the pressure inside the tower is -50KPa, the stripping steam is 60kg / h, and the light components are condensed and removed by the second flash tower condenser 3 .

[0029] 2) The resin liquid in the tank of the second flash tower is sent to the third flash tower 5 for flash evaporation through the extraction pump 4 of the second tower tank, and the resin liquid level in the tank of the second flash tower must be controlled at 40 -60%. The pressure in the third flash tower 5 tower is ultimate vacuum, and the stripping steam is 60kg / h, and the liquid resin with small molecular weight is condensed and removed through the third flash tower conde...

Embodiment 2

[0033] 1) The C5 petroleum resin polymer liquid that has been flashed once enters the feed preheater 1 to be heated, and the feed flow rate is 8m 3 / h, the shell-side medium is steam with a pressure ≥ 4.0MPa, and the heating temperature is 260°C. The heated resin polymerization liquid enters the second flash tower 2 for flash evaporation, the pressure inside the tower is -45KPa, the stripping steam is 60kg / h, and the light components are condensed and removed by the second flash tower condenser 3.

[0034] 2) The resin liquid in the second flash tower 2 tower tank is sent to the third flash tower 5 for flash evaporation through the second tower tank extraction pump 4, and the resin liquid level in the second flash tower tower tank should be controlled at the same time. 40-60%. The pressure in the third flash tower 5 tower is ultimate vacuum, and the stripping steam is 60kg / h, and the liquid resin with small molecular weight is condensed and removed through the third flash tower...

Embodiment 3

[0038] 1) The C5 petroleum resin polymer liquid enters the feed preheater 1 to be heated, and the feed flow rate is 7m 3 / h, the shell side medium is steam with a pressure ≥ 4.0MPa, and the heating temperature is 280°C. The heated resin polymerization liquid enters the second flash tower 2 for flash evaporation, the pressure inside the tower is -50KPa, the stripping steam is 65kg / h, and the light components are condensed and removed by the second flash tower condenser 3.

[0039] 2) The liquid level of the resin liquid in the second flash tower kettle is controlled at 40-60%, and sent to the third flash tower 5 for flash evaporation through the extraction pump 4 of the second tower kettle, the pressure in the tower is ultimate vacuum, and the stripping The steam is 65kg / h, and the liquid resin with small molecular weight is condensed and removed through the third flash tower condenser 9, the liquid level of the tower still is controlled at 40-60%, and the qualified C5 petroleu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com