Polymer mortar

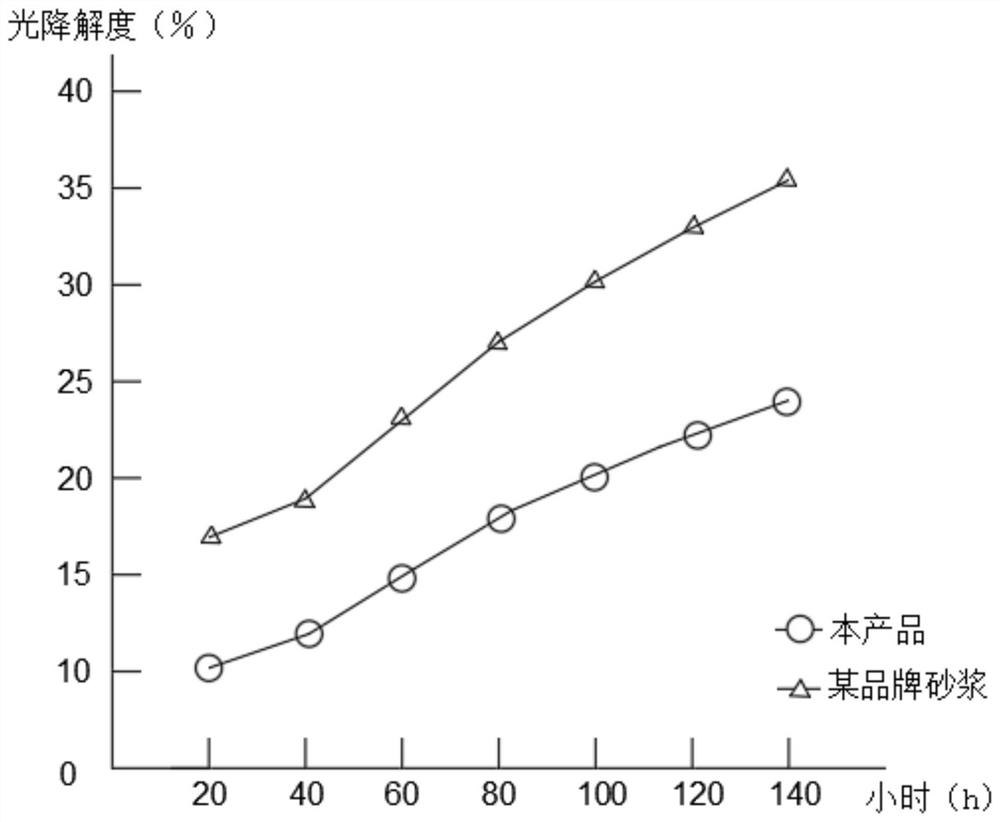

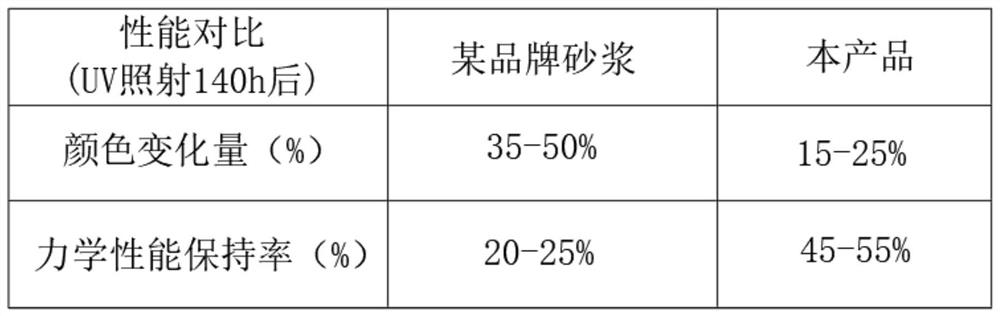

A polymer and mortar technology, applied in the field of polymer mortar, can solve the problems of mortar building safety, poor aging resistance of polymers, and aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] see Figure 1-2 , a polymer mortar comprising the following components by weight:

[0031] Cement 32%;

[0032] Quartz sand 43%;

[0033] Thickener 5%;

[0034] Polyethylene oxide 2%;

[0035] Anti-aging additive 7%;

[0036] Polypropylene fiber 1%;

[0037] Surface modified nano zinc oxide 6%;

[0038] Binder; 4%.

[0039] Further, the interior of the adhesive is composed of solidified nigrosine particles and adhesive.

[0040] Further, the surface modified nano-zinc oxide is surface-modified by coupling agent γ-aminopropyltriethoxysilane.

[0041] Further, the anti-aging additive is used in combination of three parts: ultraviolet absorber, light stabilizer and antioxidant.

[0042] Further, the ultraviolet absorber is UV-P, component: 2-(2′-hydroxyl-5′-methylphenyl) benzotriazole.

[0043] Further, the light stabilizer is HS-944.

[0044] Further, the antioxidant is Antioxidant 1010, tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol...

Embodiment 2

[0049] see Figure 1-2 , a polymer mortar comprising the following components by weight:

[0050] Cement 30%;

[0051] Quartz sand 45%;

[0052] Thickener 6%;

[0053] Polyethylene oxide 2%;

[0054] Anti-aging additives 6%;

[0055] Polypropylene fiber 1%;

[0056] Surface modified nano zinc oxide 5%;

[0057] Binder; 5%.

[0058] Further, the interior of the adhesive is composed of solidified nigrosine particles and adhesive.

[0059] Further, the surface modified nano-zinc oxide is surface-modified by coupling agent γ-aminopropyltriethoxysilane.

[0060] Further, the anti-aging additive is used in combination of three parts: ultraviolet absorber, light stabilizer and antioxidant.

[0061] Further, the ultraviolet absorber is UV-P, component: 2-(2′-hydroxyl-5′-methylphenyl) benzotriazole.

[0062] Further, the light stabilizer is HS-944.

[0063] Further, the antioxidant is Antioxidant 1010, tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythrito...

Embodiment 3

[0068] see Figure 1-2 , a polymer mortar comprising the following components by weight:

[0069] Cement 35%;

[0070] Quartz sand 40%;

[0071] Thickener 7%;

[0072] Polyethylene oxide 2%;

[0073] Anti-aging additive 7%;

[0074] Polypropylene fiber 1%;

[0075] Surface modified nano zinc oxide 4%;

[0076] Binder; 4%.

[0077] Further, the interior of the adhesive is composed of solidified nigrosine particles and adhesive.

[0078] Further, the surface modified nano-zinc oxide is surface-modified by coupling agent γ-aminopropyltriethoxysilane.

[0079] Further, the anti-aging additive is used in combination of three parts: ultraviolet absorber, light stabilizer and antioxidant.

[0080] Further, the ultraviolet absorber is UV-P, component: 2-(2′-hydroxyl-5′-methylphenyl) benzotriazole.

[0081] Furthermore, the light stabilizer is HS-944.

[0082] Further, the antioxidant is Antioxidant 1010, tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythrit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com