Rapid falling-off equipment for concrete cushion layer

A concrete cushion, fast technology, applied in the direction of stone processing equipment, work accessories, stone processing tools, etc., can solve the problems of difficult to remove the cushion, complicated operation, uneven removal, etc., to avoid dust everywhere and increase the breakdown depth. , the effect of improving the shedding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

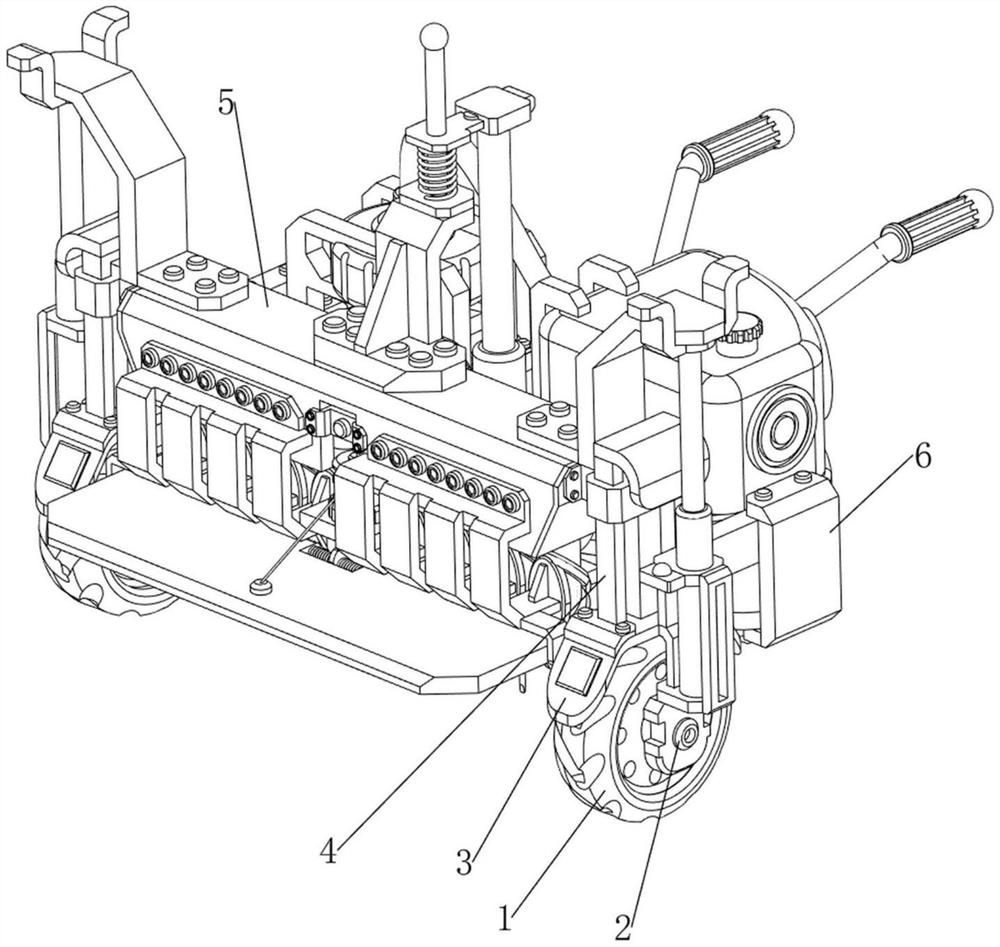

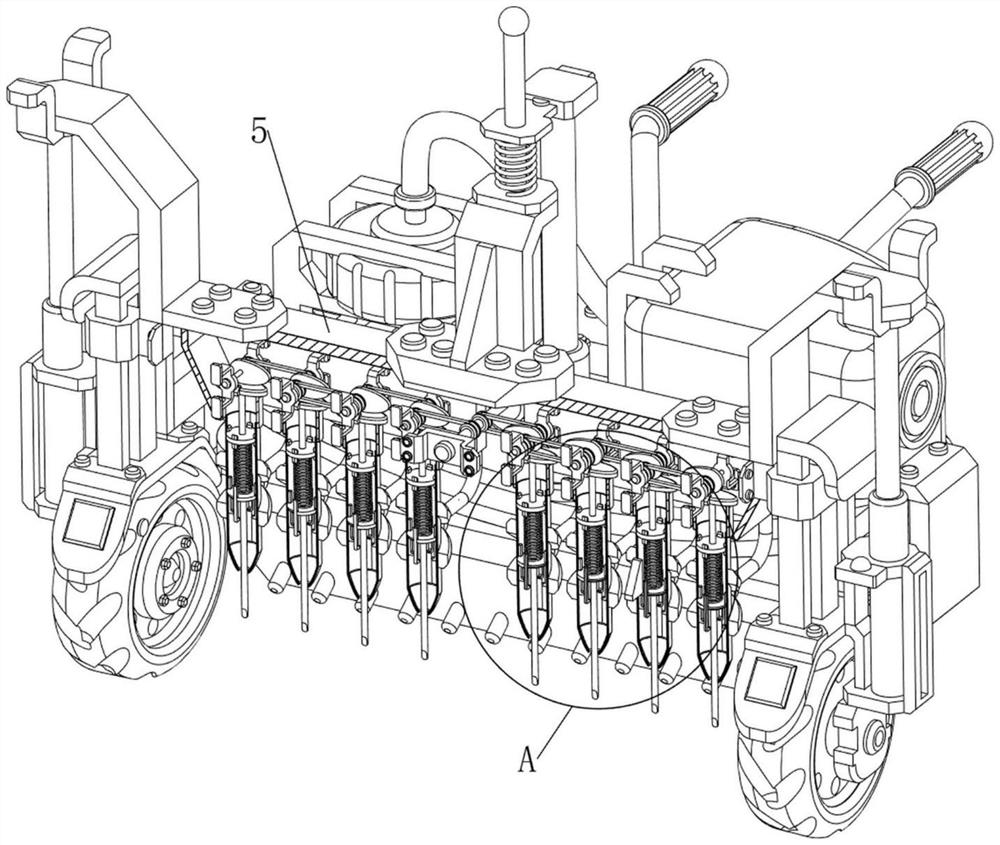

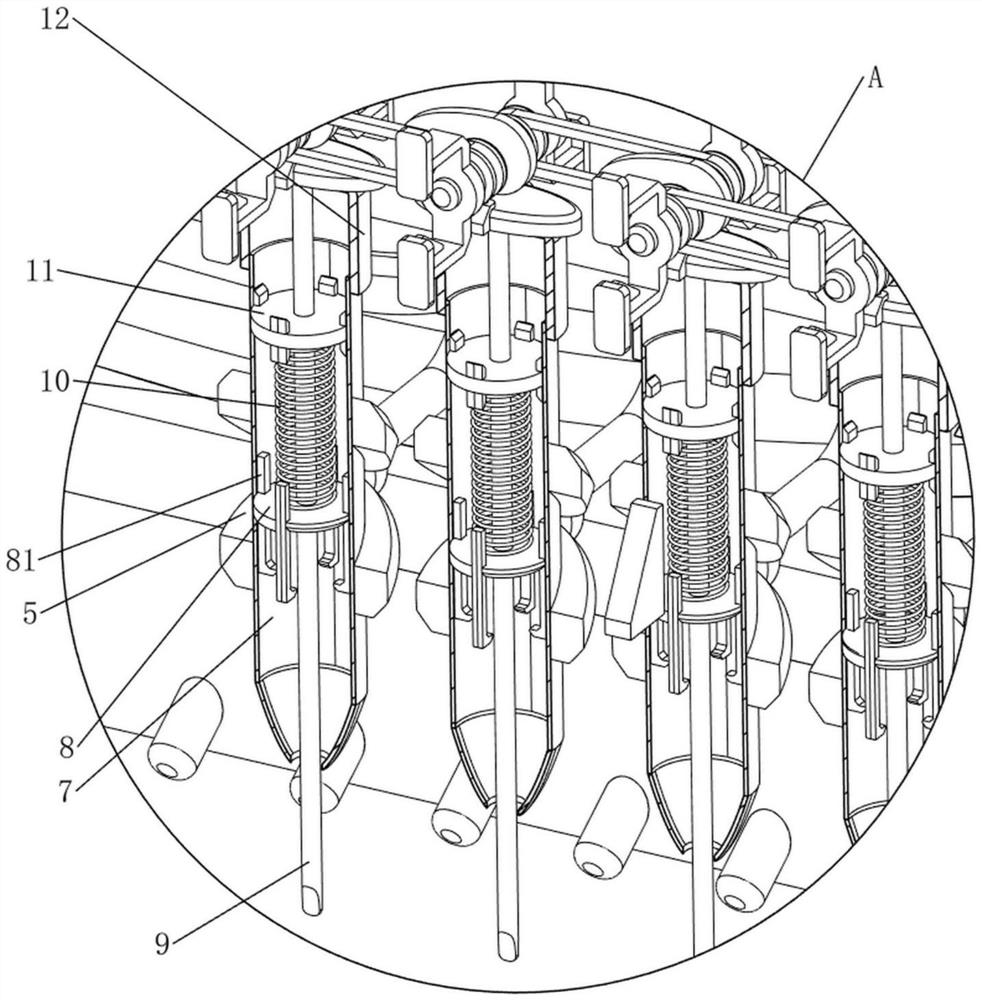

[0023] A fast shedding equipment of a concrete mat, such as Figure 1-6 As shown, including the front wheel 1, the first rotating shaft 2, the first support frame 3, the guide frame 4, the first fixing frame 5, the bottom frame 6, the casing 7, the slider 8, the guide block 81, the top rod 9, The first spring 10, the limit block 11, the slider 12, the connecting frame 13, the second rotating shaft 14, the control box 15, the contact switch 16, the rear wheel 141, the elevator 17, the vibration mechanism 18, extrusion mechanism 19 and the mobile mechanism 20, the bottom of the chassis 6 is provided with an armrest, and the bottom frame is provided with a guide frame 4 in front of the front portion, and the sliding frame is slidably equipped between the two guide frames 4, and the guide frame 4 is provided. There is a first support frame 3, and the lower portion of the first support frame 3 is provided with a first rotating shaft 2 by a bearing, and a front wheel 1 is provided on the...

Embodiment 2

[0030] On the basis of Example 1, such as Figure 5 , Figure 14 and Figure 15As shown, it includes a protective mechanism 21, and the protective mechanism 21 includes a third support frame 211, a baffle 212, a fourth support frame 213, a second deceleration motor 214, a fifth axis 215, a winding wheel 216, a drawn wire 217. , The sixth axis 218 and the torsion spring 219, the lower portion of the lower portion of the first fixing frame 5 is provided with the third support frame 211, and the first fixing frame 5 is fixed in the middle of the front side of the lower portion, and the fourth support frame 213, the fourth support frame are fixed. At the top of the 213, a second reduction motor 214 is attached, and the output shaft of the second reduction motor 214 is provided with a fifth axis 215 through a coupling. The upper portion of the fifth axis 215 is welded with winding wheel 216, the fourth support frame 213 lower portion and two A sixth axis 218 is connected between the third...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com