Petroleum type soil pollution remediation process for promoting crude oil degradation

A technology of soil pollution and petroleum, applied in the field of soil remediation, can solve the problems of inability to achieve long-term effective degradation of petroleum hydrocarbons, increase the cost of remediation, and incapable of soil remediation treatment, achieve long-term effective degradation of petroleum hydrocarbons in crude oil, avoid unreasonable dosage, The effect of high adsorption and degradation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

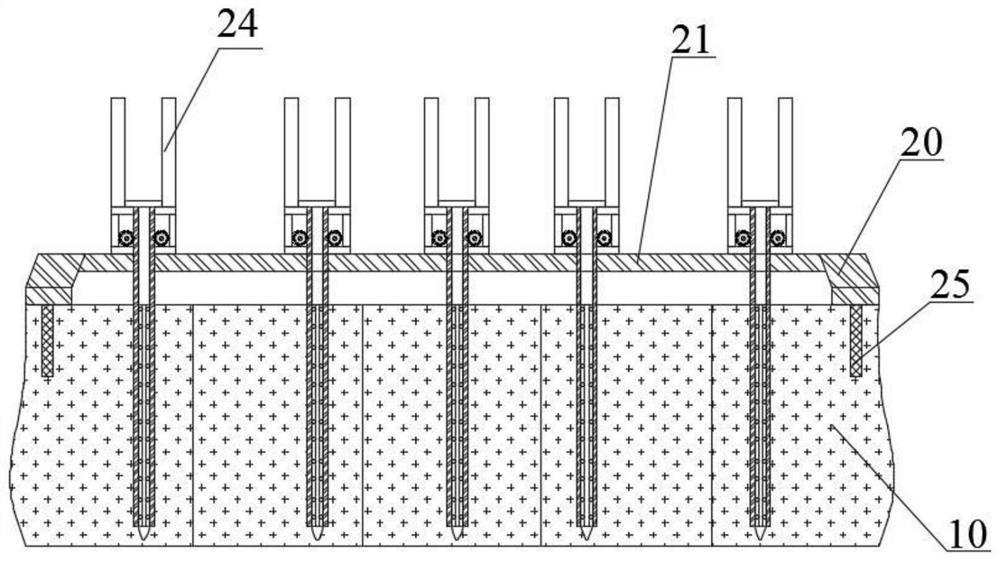

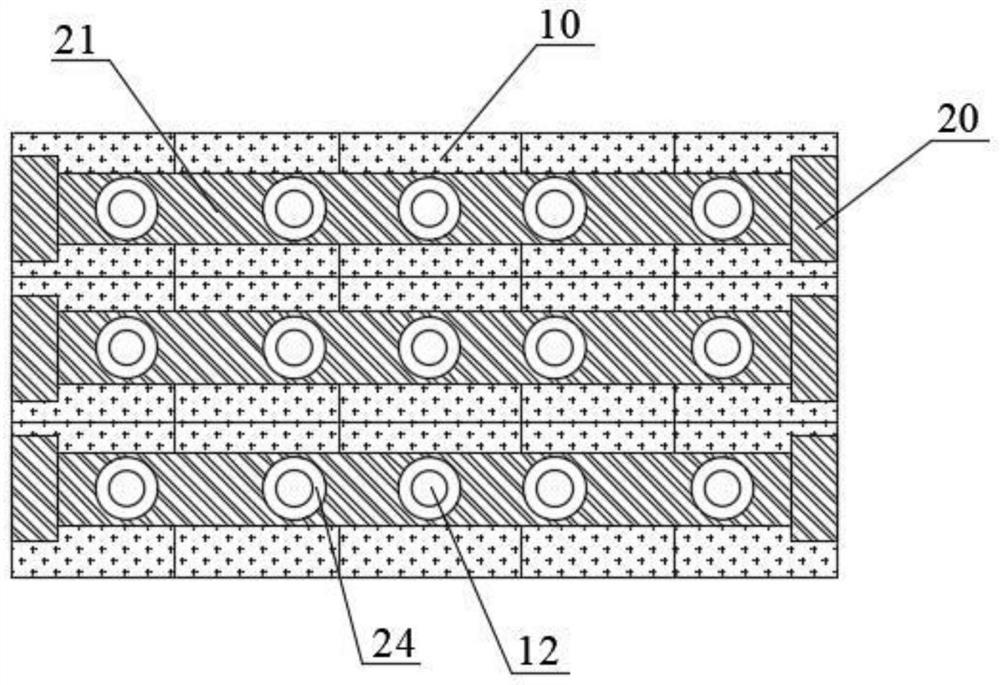

[0034] Such as Figure 2-4As shown, the present embodiment provides a petroleum soil sampling device, including a plurality of support columns 20 arranged on both sides of the gridded soil area 10, and the support columns 20 on both sides are connected with A plurality of installation plates 21 above the area 10, a plurality of installation plates 21 are provided with an installation cylinder 22 corresponding to each gridded soil area 10, a cavity 23 is provided in the installation cylinder 22, and a cavity 23 is provided above the installation cylinder 22. The vertical limiting plate 24, the limiting plate 24 and the cavity 23 are provided with a sampling mechanism that can vertically extend into the gridded soil area 10, and the bottom of the support column 20 is provided with a sampling mechanism that extends into the gridded soil area 10. The counterweight pile 25.

[0035] Sampling mechanism comprises drilling rod 11, and the top of drilling rod 11 is provided with the s...

Embodiment 2

[0039] Such as Figure 5-6 As shown, this embodiment provides a petroleum soil pollution remediation system that promotes crude oil degradation, including a plurality of pipe piles 30 that are arranged in the limiting plate 24 and the cavity 23 and extend vertically into the gridded soil area 10 , the bottom of the pipe pile 30 extends to the bottom of the gridded soil area 10, the top of the pipe pile 30 extends out of the limit plate 24, and the pipe pile 30 is located in the gridded soil area 10 and communicates with a plurality of horizontally extending extraction A solenoid valve 32 is provided at the junction of the liquid feeding pipe 31 , the extraction liquid feeding pipe 31 and the pipe pile 30 , and a plurality of vacuum liquid feeding ports 33 are provided on the path of the extraction liquid feeding pipe 31 .

[0040] The top of each pipe pile 30 is connected with a flange two-way valve 34, and a connecting pipe 35 is connected between adjacent flange two-way valv...

Embodiment 3

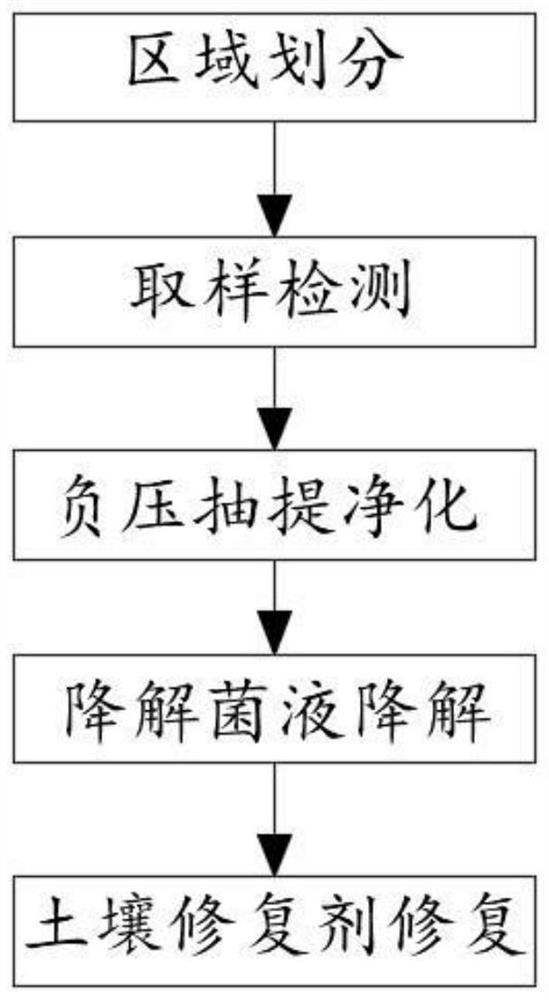

[0045] Such as Figure 1-6 As shown, the present embodiment provides a petroleum-based soil pollution remediation process that promotes degradation of crude oil, comprising the following steps:

[0046] Regional division: evenly divide the contaminated petroleum soil into multiple regions to form multiple gridded soil areas 10; the length and width of each gridded soil area 10 are 3-5m, and the depth is 0.6-1.5m .

[0047] Sampling detection: through the petroleum soil sampling device, the soil corresponding to different regions and different depths is taken out from multiple sampling holes 15, and the petroleum hydrocarbon content is detected by the soil petroleum hydrocarbon detector. Specifically, the driving motor drives the driving gear 26 to rotate, the driving gear 26 drives the drill rod 11 to rotate and lift, and the driven gear 27 assists in rotating support to keep the drill rod 11 stable to rotate and lift. A plurality of sampling holes 15 are used to take out so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com