Coke oven gas desulfurization tower

A coke oven gas and desulfurization tower technology, applied in the field of desulfurization towers, can solve the problems of cumbersome sediment cleaning, increased costs, incomplete desulfurization, etc., to achieve the effect of ensuring success rate, improving effect and efficiency, and delicate contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the techniques of the present invention, the creation characteristics, the purpose and efficacy are readily understood, and the present invention is further illustrated in connection with the specific embodiments.

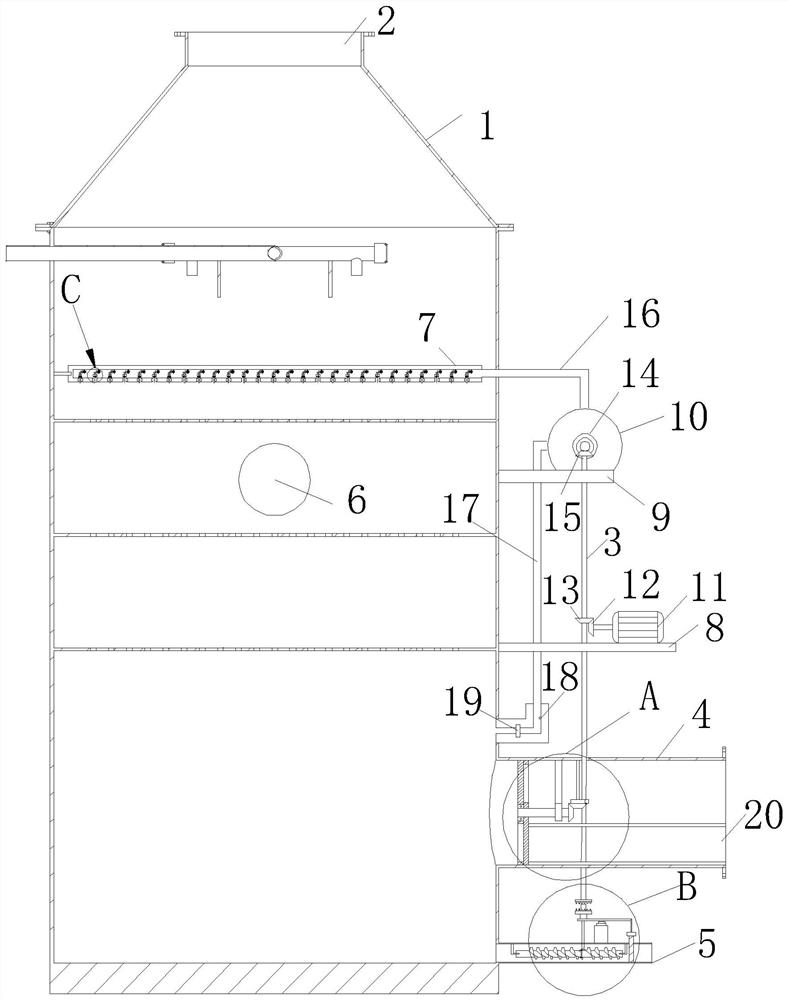

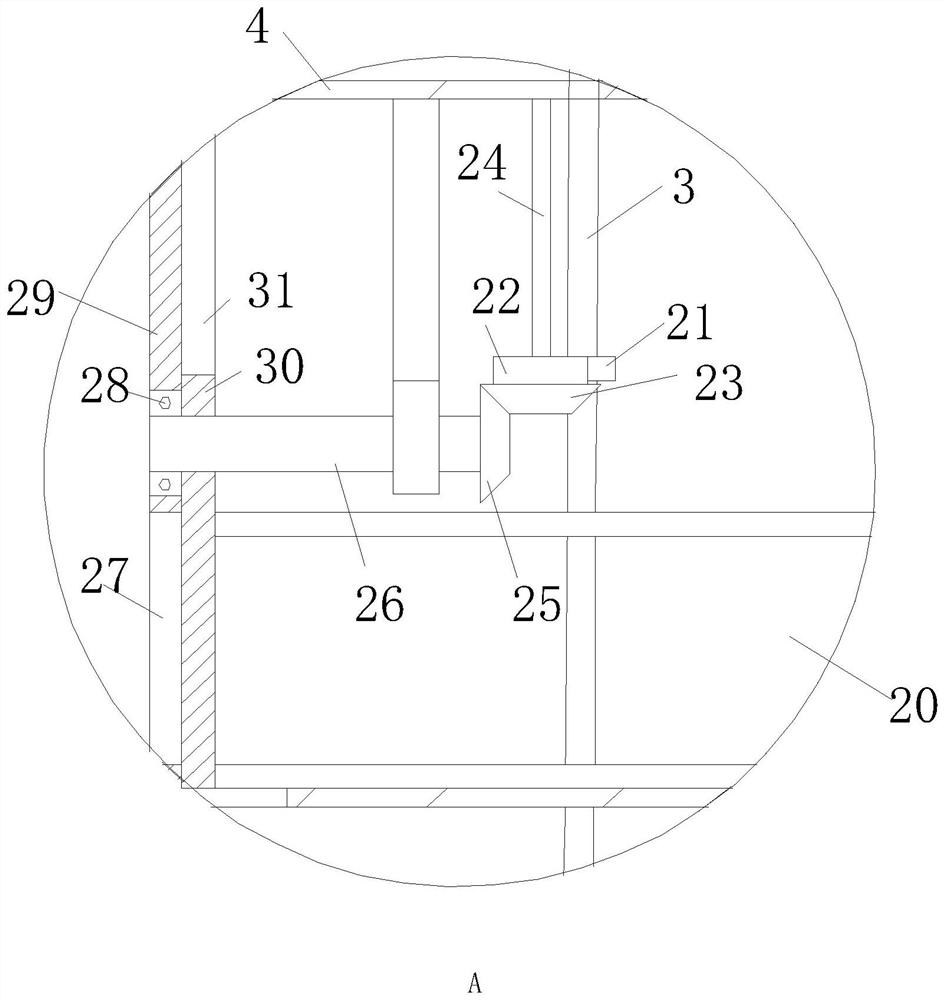

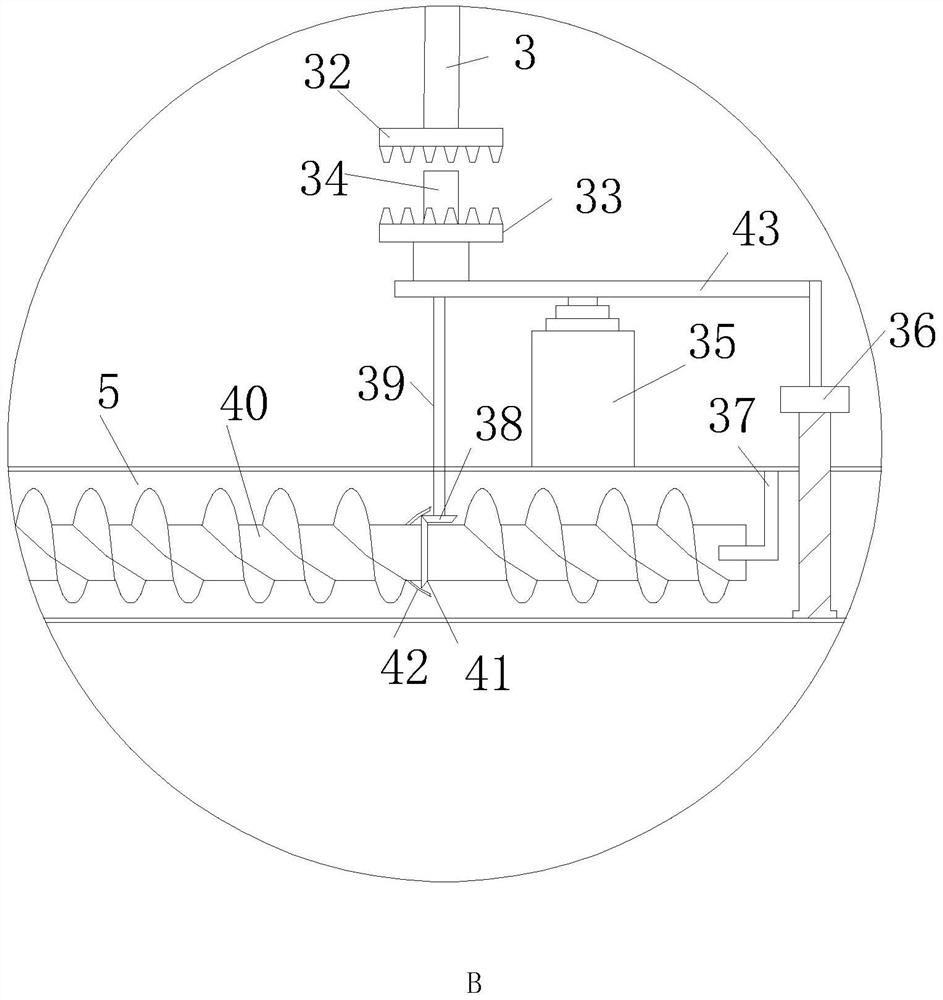

[0024] Such as Figure 1 - Figure 6As shown, the coke oven gas desulfurization tower according to the present invention includes a furnace body 1, and an exhaust port 2 is opened at the top center of the furnace body 1 and the exhaust port 2 and the inside of the furnace body 1 are connected, and the furnace body 1 The bottom end side is opened with a slurry port 5, and the furnace body 1 is located at the top of the shorter opening 5, and there is a pipeline 4, and the inner portion of the line 4 is provided in the line 20, the intake port 20 and the furnace body. 1 The internal communication, the pipeline 4, the propellant port 5, and the air port 20 are all in the same, and the side of the furnace body 1 is connected to the second conduit 17, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com