Hydraulic jet drilling pipe column and hydraulic jet drilling method

A technology of hydraulic jetting and drilling pipes, which is applied to drilling equipment and methods, drilling with liquid/gas jets, drilling equipment, etc., and can solve the problems of multiple operating links, difficulty in drilling pipe strings, and high operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

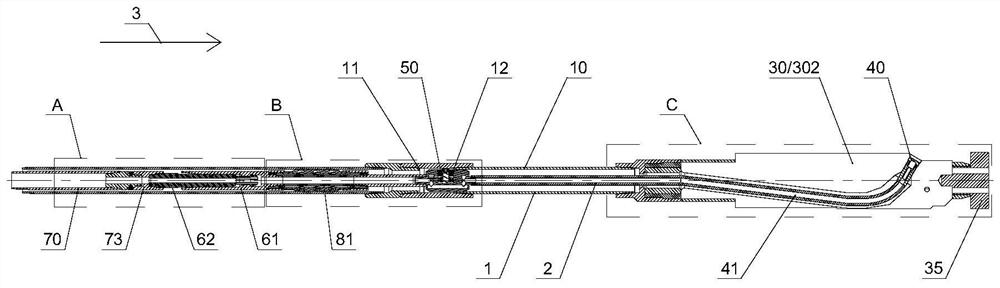

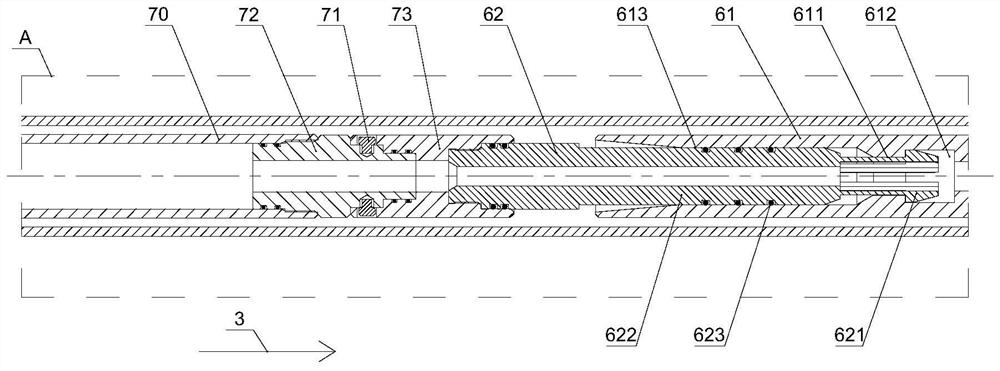

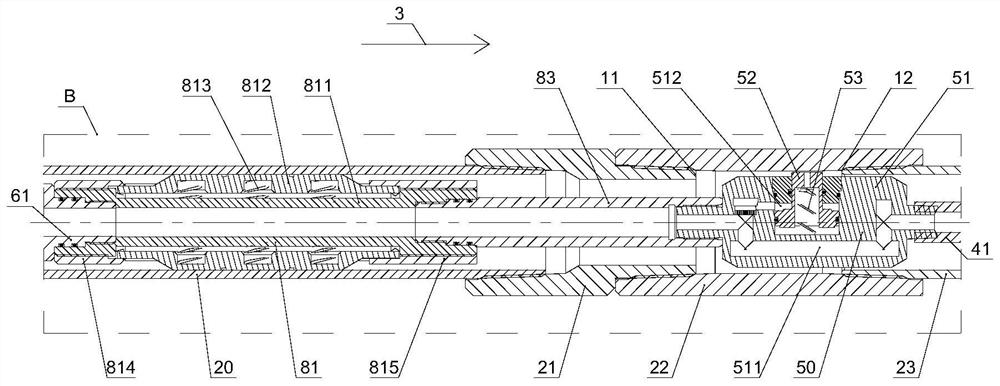

[0085] The invention provides a hydraulic jet drilling string, such as Figure 1 ~ Figure 4 As shown, the hydraulic jet drilling string includes: an outer pipe string 1 and an inner pipe string 2 arranged in the outer pipe string 1; the outer pipe string 1 includes: an outer pipe body 10 and a guide 30, and the outer pipe body 10 The inner wall is provided with a first step 11 and a second step 12 distributed along the direction 3 from bottom to top; the guide 30 is connected to the lower end of the outer tube body 10, and is provided with a hose traveling channel 301; the inner tube column includes: a nozzle 40 , the injection hose 41, the action conversion mechanism 50, the first butt joint 61, the second butt joint 62, and the inner tubing string running into the oil pipe 70; the injection hose 41 is located in the hose travel passage 301, and can move in the hose travel passage 301, The nozzle 40 is connected to the lower end of the injection hose 41; the action conversion...

Embodiment 2

[0113] The present invention provides a hydraulic jet drilling method, using the above hydraulic jet drilling string, such as Figure 19 As shown, the hydraulic jet drilling method includes: Step S10, installing the nozzle 40, the jetting rubber hose 41, the action conversion mechanism 50 and the first butt joint 61 in the outer pipe string 1; Step S20, lowering the outer pipe string 1 into the to the designated formation; step S30, run in the second butt joint pipe 62 and the inner pipe string into the oil pipe 70 in sequence, so that the second butt joint pipe 62 is plugged and communicated with the first butt pipe 61; step S40, pass into the inner pipe string Mortar liquid, the mortar liquid entering the conversion pipe body 51 makes the positioning and limiting pin shaft 52 shrink inwardly, and at the same time, the mortar liquid is sprayed outward through the nozzle 40 to open a window on the casing; step S50, push the inner pipe string down to make the nozzle 40 enters t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com