Intelligent vertical oxidation electrophoresis production line

A production line, vertical technology, applied in the field of vertical oxidation electrophoresis production equipment, to achieve the effect of improving work efficiency and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The following describes an intelligent vertical oxidation electrophoresis production line according to the first embodiment of the present application with reference to the accompanying drawings.

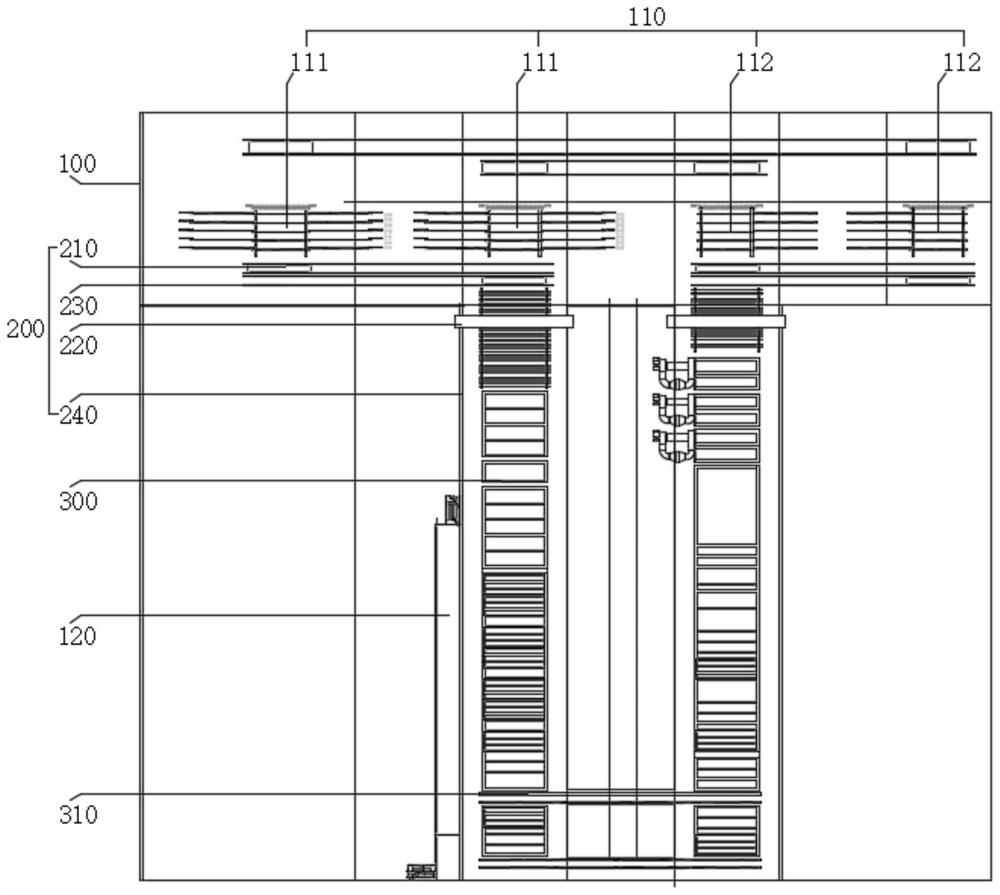

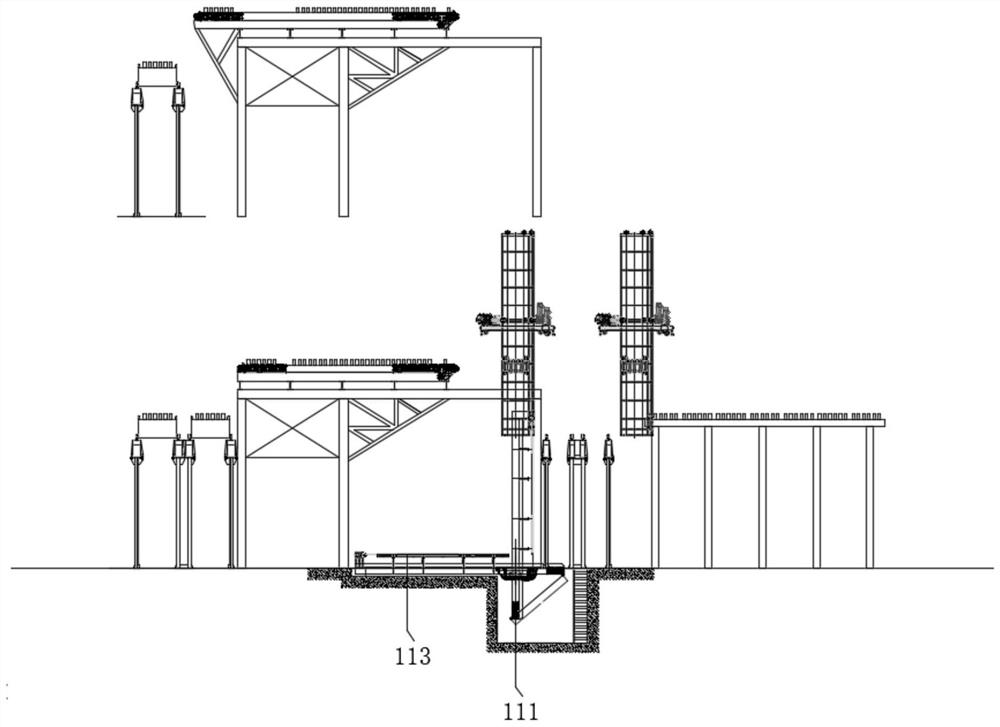

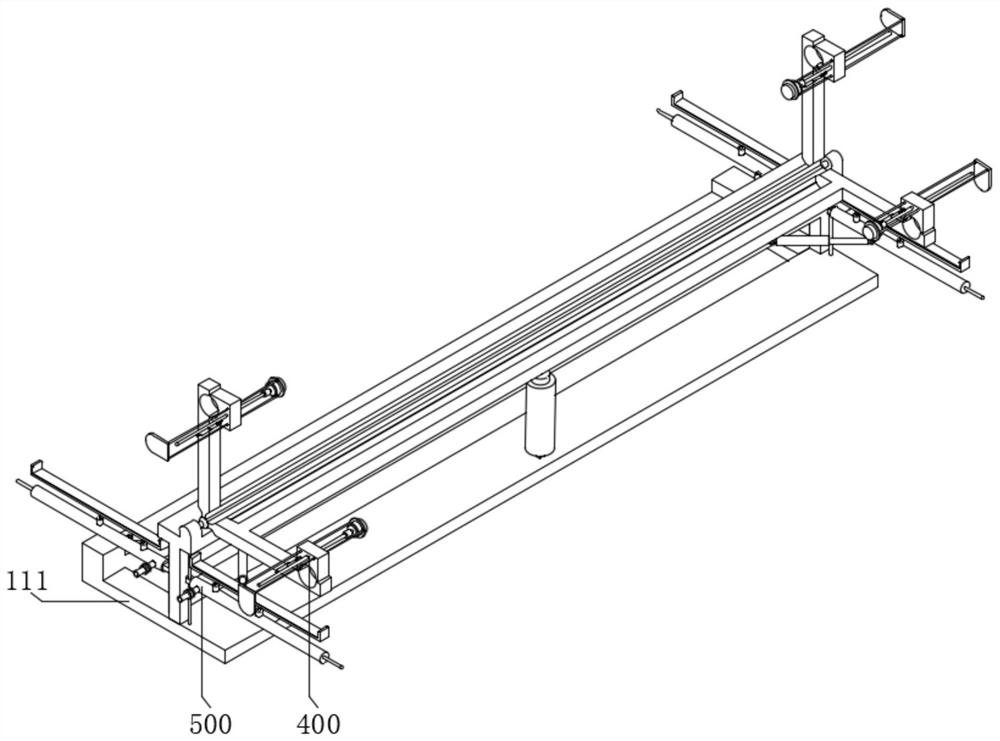

[0043] like figure 1 As shown, the intelligent vertical oxidation electrophoresis production line according to the embodiment of the present application includes: a production plant 100 , a conveying mechanism 200 and a processing pool 300 .

[0044] The conveying mechanism 200 is used for conveying the workpiece to be processed to the processing pool 300 for processing and processing.

[0045] The production plant 100 is provided with a double-station loading and unloading structure 110, and the double-station loading and unloading structure 110 has two loading stations 111 and two unloading stations 112;

[0046] The material conveying mechanism 200 includes a crossover car 210 and a material conveyance carriage 220. The production plant 100 is provided with a crossover ra...

Embodiment 2

[0054] The following describes an intelligent vertical oxidation electrophoresis production line according to the second embodiment of the present application with reference to the accompanying drawings.

[0055] like figure 1 As shown, the intelligent vertical oxidation electrophoresis production line according to the embodiment of the present application includes: a production plant 100 , a conveying mechanism 200 and a processing pool 300 .

[0056] The conveying mechanism 200 is used for conveying the workpiece to be processed to the processing pool 300 for processing and processing.

[0057] The production plant 100 is provided with a double-station loading and unloading structure 110, and the double-station loading and unloading structure 110 has two loading stations 111 and two unloading stations 112;

[0058] The material conveying mechanism 200 includes a crossover car 210 and a material conveyance carriage 220. The production plant 100 is provided with a crossover r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com