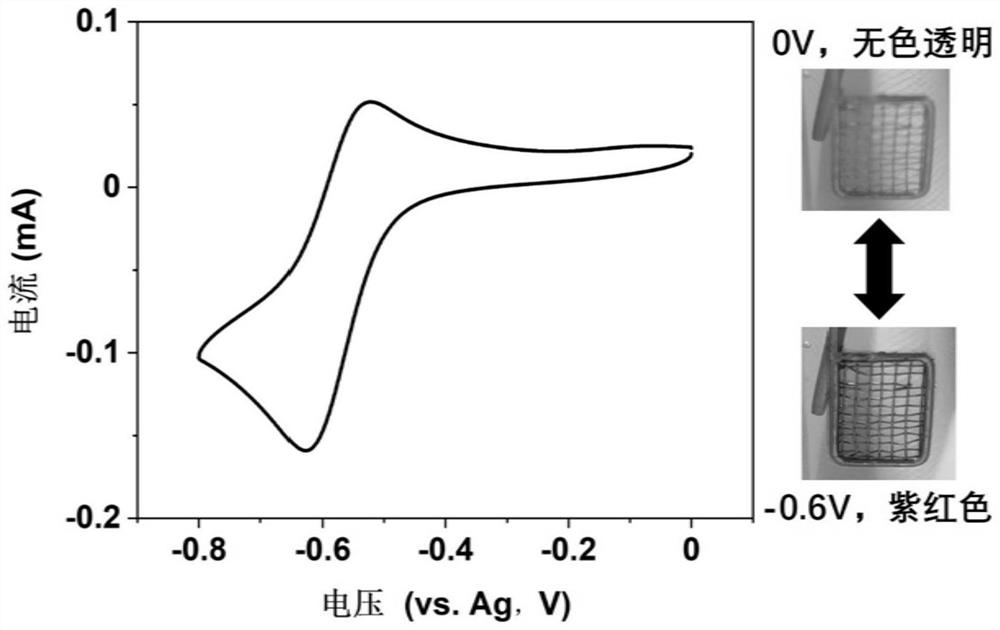

Para-aryl substituted pyridinium salt derivative electrochromic material and preparation method thereof

A technology of electrochromic materials and derivatives, applied in the direction of color-changing fluorescent materials, chemical instruments and methods, organic chemistry, etc., can solve the problems of high mortality and human toxicity, and achieve simple synthesis, low toxicity and high yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A preparation method of a para-aryl-substituted pyridinium salt derivative electrochromic material 1-benzyl-4-phenylpyridinium bromide, comprising the following steps:

[0049] 1) Mix pyridine 4-boronate, chlorobenzene, sodium hydroxide, palladium chloride, tri-tert-butylphosphine (molar ratio 1:1:8:0.5:2) and water evenly, and place in N 2 Stir at room temperature under atmosphere for 20-30min, and reflux at 100°C for 14h; after the reaction is completed, cool the solution to room temperature, filter, and concentrate the filtrate; recrystallize with ethyl acetate to obtain 4-phenylpyridine;

[0050] 2) Mix 4-phenylpyridine, benzyl bromide (molar ratio 1:2) and DMF obtained in 1) evenly, reflux at 80-85°C for 0.1h, and remove the solvent by rotary evaporation; recrystallize with dichloromethane to obtain the molecular structure formula 1-benzyl-4-phenylpyridinium bromide salt electrochromic material, its 1 H NMR spectrum as figure 1 shown. The overall yield for the t...

Embodiment 2

[0054] A preparation method of an electrochromic material 1-benzyl-4-(3-(trifluoromethyl)phenyl)pyridinium bromide salt substituted by a para-aryl group, comprising the steps of:

[0055] 1) Mix 4-pyridine boronic acid, 3-(trifluoromethyl)bromobenzene, cesium fluoride, tridibenzylideneacetone palladium (molar ratio 1:2:4:0.01) and DMF evenly, and place in N 2 Stir at room temperature under atmosphere for 20-30min, reflux at 120°C for 70h; after the reaction is complete, cool the solution to room temperature, filter, and concentrate the filtrate; recrystallize with ethyl acetate to obtain 4-(3-(trifluoromethyl)phenyl) pyridine;

[0056] 2) Mix 4-(3-(trifluoromethyl)phenyl)pyridine, benzyl bromide (molar ratio 1:2.5) and DMF obtained in 1) evenly, reflux at 80-85°C for 2 hours, and remove the solvent by rotary evaporation; Obtain molecular structure formula 1-benzyl-4-phenylpyridinium bromide electrochromic material with dichloromethane recrystallization, its 1 H NMR spectrum ...

Embodiment 3

[0060] A preparation method of an electrochromic material 1-benzyl-4-(3-thiophene) pyridinium bromide salt substituted by a para-aryl group, comprising the steps of:

[0061] 1) Mix 4-chloropyridine, 3-(boronic acid) thiophene, potassium tert-butyl, bis(tri-tert-butyl)palladium, triphenylphosphine (molar ratio 1:1.5:5:0.025:0.5) and dioxygen Hexacyclic mixed well, in N 2 Under atmosphere, stir at room temperature for 20-30 minutes, and reflux at 100°C for 46 hours; after the reaction is completed, cool the solution to room temperature, filter, and concentrate the filtrate; recrystallize with ethyl acetate to obtain 4-(3-thiophene)pyridine;

[0062] 2) Mix 4-(3-thiophene)pyridine, benzyl bromide (molar ratio 1:2) and diethyl ether obtained in 1) evenly, reflux at 80-85°C for 2 hours, and remove the solvent by rotary evaporation; recrystallize with dichloromethane to obtain Molecular structural formula 1-benzyl-4-(3-thiophene) pyridinium bromide electrochromic material, its 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com