Ultra-wide steel box girder total splicing cross slope control method

A control method and steel box girder technology, applied in the direction of manufacturing tools, auxiliary devices, workpiece edges, etc., can solve the problems affecting the overall structural accuracy of steel box girder segments, difficult to effectively guarantee accuracy control, and reducing bridge comfort, etc. The method is simple and feasible, the impact is reduced, and the effect of strong versatility is achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

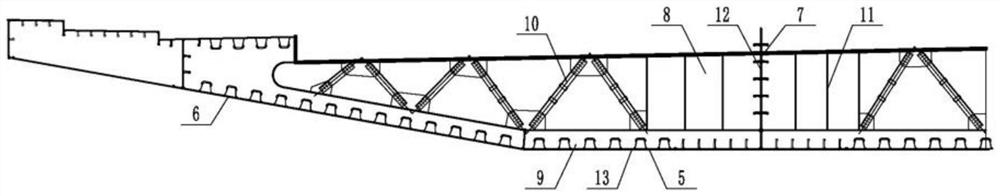

[0028] Below in conjunction with specific embodiment and Figure 1 to Figure 6 The present invention will be described in further detail, but the embodiments of the present invention are not limited thereto.

[0029] The invention provides a method for controlling the transverse slope of an ultra-wide steel box girder assembly, which specifically includes the following steps:

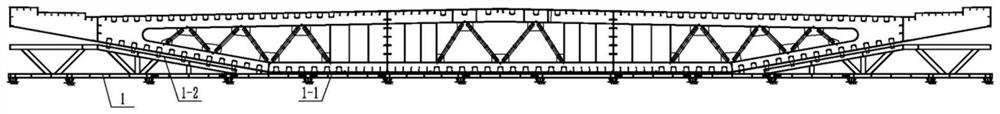

[0030] Step 1: According to the linear requirements of the steel box girder bottom plate, the assembled tire frame 1 is manufactured, and the assembled platform of the assembled tire frame 1 is composed of the horizontal tread 1-1 in the middle and the two ends connected to the horizontal tread 1-1. Symmetrically inclined tread 1-2 constitutes, such as figure 1 shown.

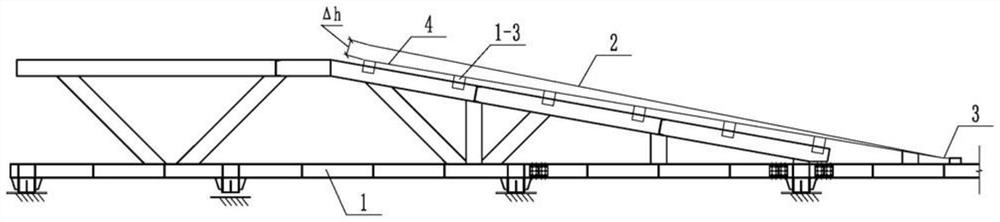

[0031] Step 2: Arranging the tooth plate 1-3 on the horizontal tread 1-1 and the inclined tread 1-2, and the elevation of the tooth plate 1-3 is determined according to the design elevation control line 2 of the steel box girder floor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com