Argon-rich mixed gas shielded welding method for NM450 high-strength wear-resistant steel

A high-strength wear-resistant steel and mixed gas technology, applied in the field of wear-resistant steel welding, can solve the problems of decreased crack resistance, increased cost, decreased plastic toughness of welds, etc. The effect of resistance to cold crack susceptibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

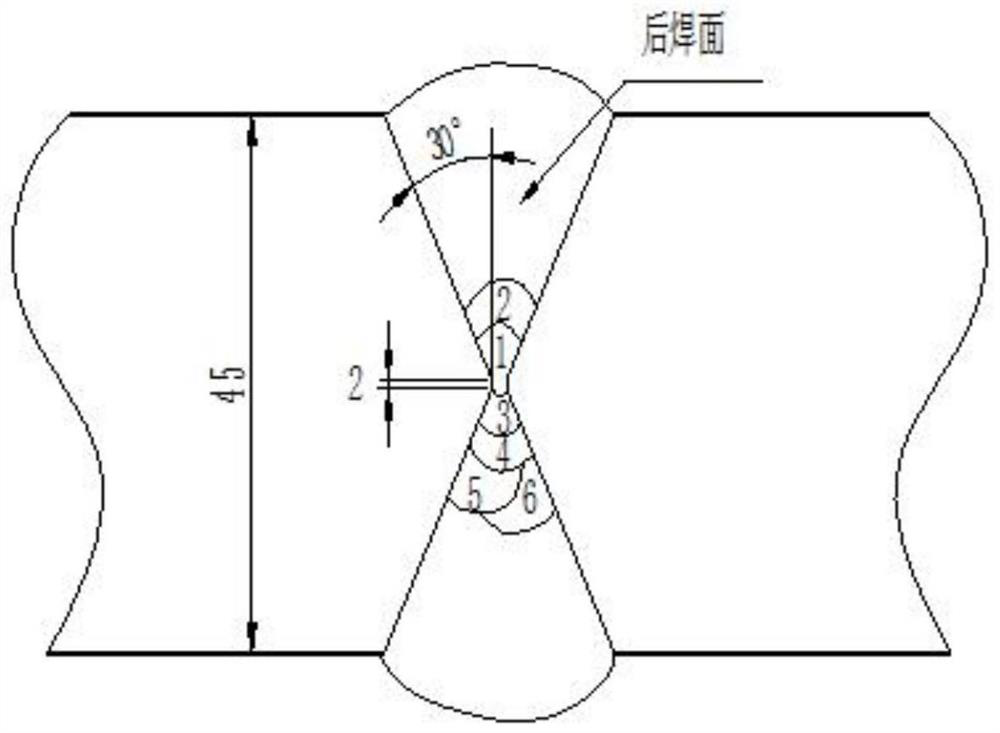

[0021] 1. The NM450 high-strength wear-resistant steel plate with a carbon equivalent of 0.66% and a hardness level of HB450 produced by quenching and tempering treatment is a combination of 45mm+45mm, and the size of the test plate is 300mm×150mm×45mm;

[0022] Matching welding materials:

[0023] The chemical composition of welding wire HS-70 is C: ≤0.12%, Mn: 1.40-1.70%, Si: 0.35-0.80%, P: ≤0.020%, S: ≤0.002%, Mo: 0.20-0.50 %, Ni: 1.30-1.50%, Cr: 0.20-0.40%, the balance is Fe and unavoidable impurities; protective gas: 80% Ar ten 20% CO2 mixed gas; such as figure 1 As shown, the groove adopts a symmetrical double-sided X-shaped groove, the groove angle is 60°, the blunt edge is 2mm, and the groove gap is 1-2mm; before welding, remove the rust and oil within 20mm around the weld, and grind the slope Metallic luster leaks from the mouth;

[0024] 2. Preheat the NM450 wear-resistant steel to be welded to 175°C, and control the interpass temperature at 100-200°C;

[0025] 3....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com