Electronically commutated electric machine, brake device and method for producing electronically commutated electric machine

An electronic commutation and rotor technology, applied in the manufacture of motor generators, brakes, electric components, etc., to achieve the effect of simple interchangeability and large installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

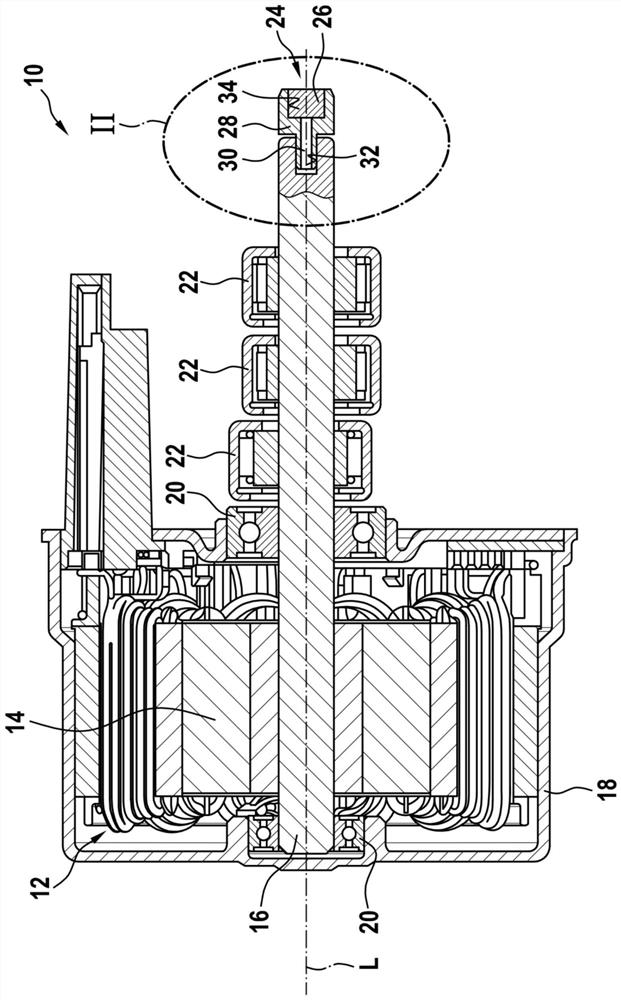

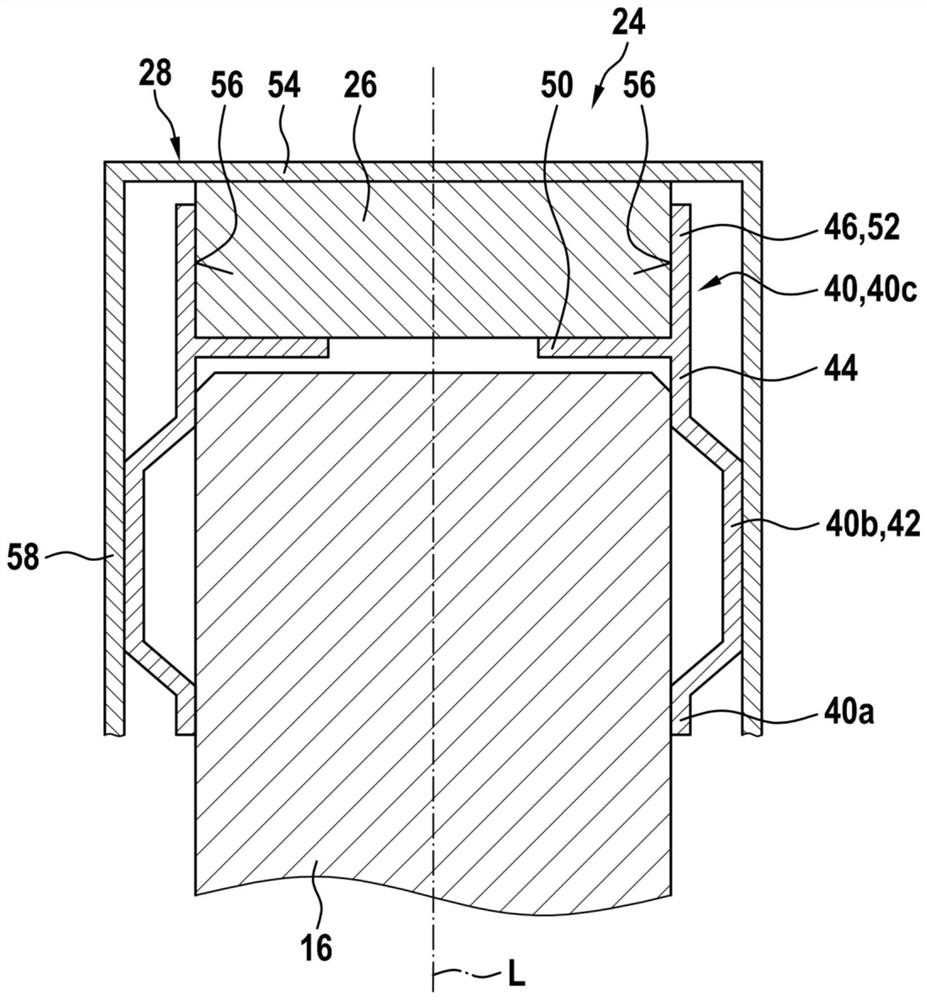

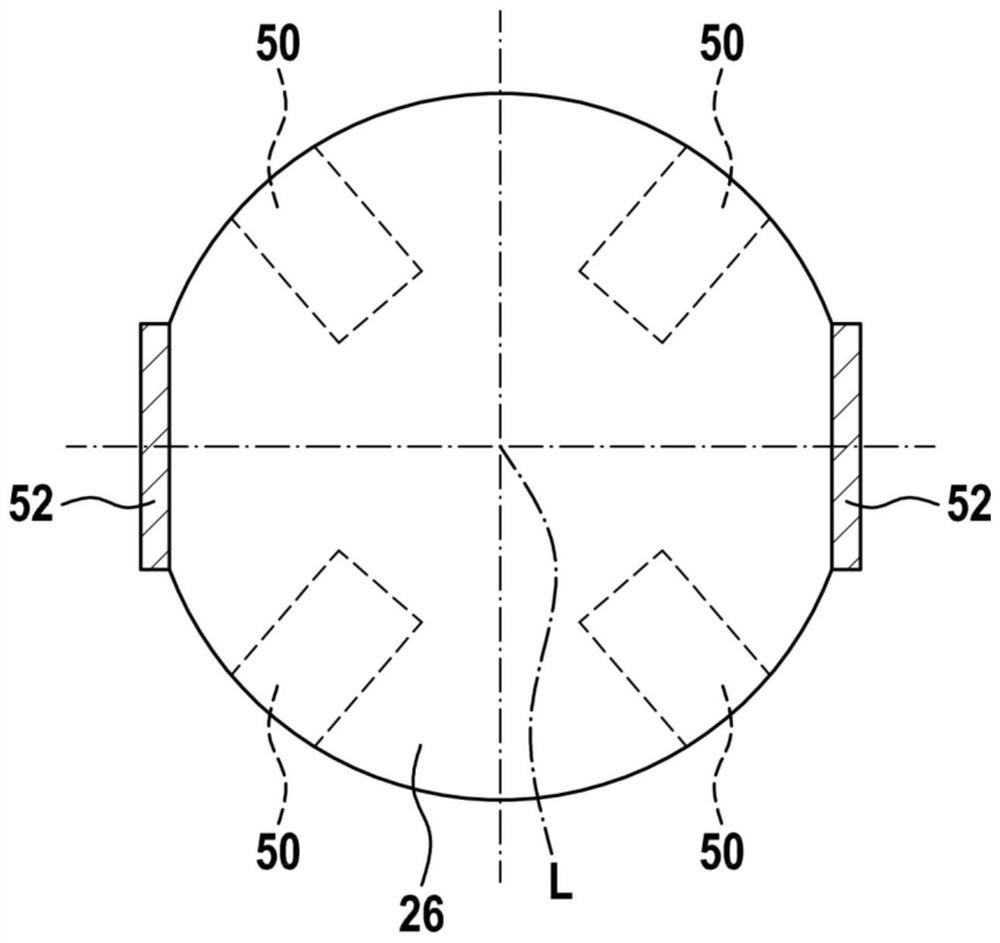

[0021] figure 2 The end of the rotor shaft 16 of an electronically commutated electric machine equipped with a signal transmitter 24 is shown. This end is situated opposite a second, unmarked end on which the rotor of the electric machine is mounted, cf. figure 1 . The rotor shaft 16 always has a constant outer diameter and is cut perpendicular to the longitudinal axis L, thus having a shaft end side oriented perpendicular thereto. The transition from the shaft end side to the shaft circumference is designed as a chamfered bevel, but can also alternatively be embodied as a rounded corner.

[0022] A clamping body 40 in the form of a tolerance ring is attached to the illustrated end of the rotor shaft 16 . The clamping body 40 is embodied as a cylindrical sleeve, which can be embodied closed on the circumferential side or slotted on the circumferential side. Slotted sleeves can be produced cost-effectively by bending sheet metal strips.

[0023] Seen in the direction of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com