Dynamic target tracking accuracy test device for photoelectric detection equipment

A photoelectric detection and dynamic target technology, applied in the direction of radio wave measurement systems, instruments, etc., can solve the problems of limited installation space, small tracking range, and poor versatility, and achieve the effect of large installation space, small volume limit, and good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

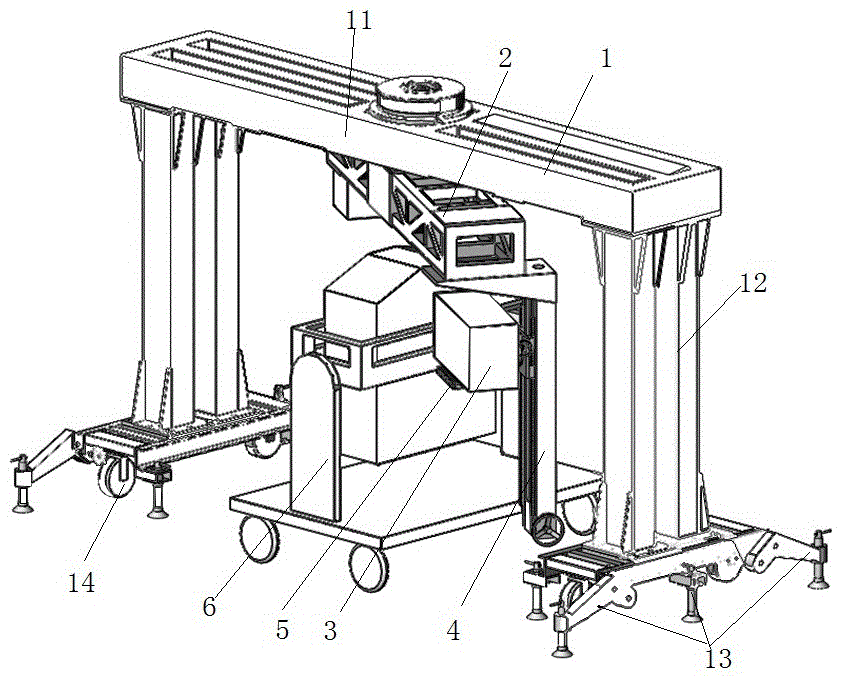

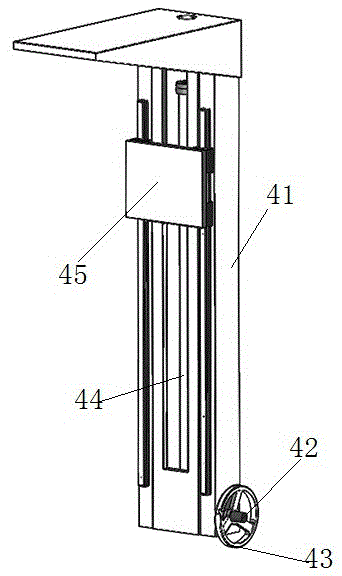

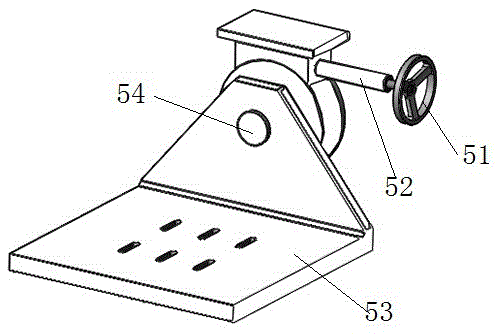

[0021] Such as Figure 1 to Figure 3 Shown, a kind of embodiment of photoelectric detection equipment dynamic target tracking precision test device, the test device in this embodiment comprises portal frame 1, and portal frame 1 has two vertical legs 12 of upper beam 11 and two ends, in On the upper beam 11, the position corresponding to the photoelectric detection device 6 to be tested is provided with a central rotating shaft extending in the up and down direction, and a cantilever beam 2 is installed coaxially rotating at the position of the central rotating shaft, and the cantilever beam 2 is far away from the central rotating shaft. The target source 3 for simulating the target tracked by the photoelectric detection equipment to be tested is installed at the far end of the position, and the cantilever beam 2 can carry the target source 3 in the range of the portal frame 1 to make a circumferential revolution. The cantilever beam 2 here Driven by a rotating motor, the rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com