Distribution network overhead line pole erecting and removing device

A technology for overhead lines and poles, which is applied in the direction of overhead lines/cable equipment, towers, building types, etc. It can solve problems such as the inability to guarantee the personal safety of operators, threats to personal and power grid equipment, and hidden dangers of falling objects. The effect of improving operation efficiency, optimizing operation links, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

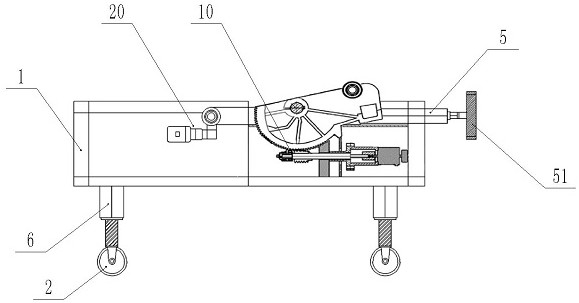

[0028] In order to make the purpose and technical solution of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

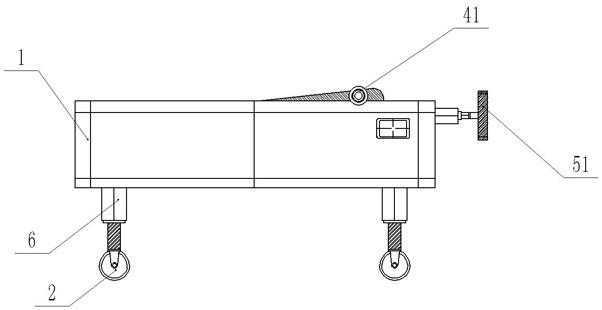

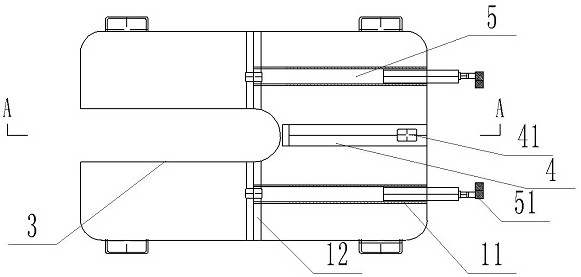

[0029] Such as Figure 1~Figure 3 As shown, a kind of vertical withdrawal pole device for distribution network overhead lines according to the present invention includes a chassis 1 and a control mechanism. Mechanically driven and assisted, the control module controls the movement of the moving wheel 2, which is used for the movement of the vertical withdrawal rod device within a short distance. At the same time, preferably, the moving wheel 2 has a locking mechanism and a self-locking function to ensure that it is firmly fixed in the operation project at the target location.

[0030] The front part of the chassis 1 is provided with a pole channel plate 3. The pole channel plate 3 is an open slot from the middle of the chassis 1 to the front through the chassis 1 vertically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com