Pixel unit with driving IC, light-emitting device comprising pixel unit and manufacturing method thereof

A light-emitting device and pixel unit technology, which is applied in the fields of electrical components, semiconductor/solid-state device manufacturing, and instruments, can solve the problems of high cost of control circuits and increased costs, and achieve low production costs, high integration, and good mass production rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

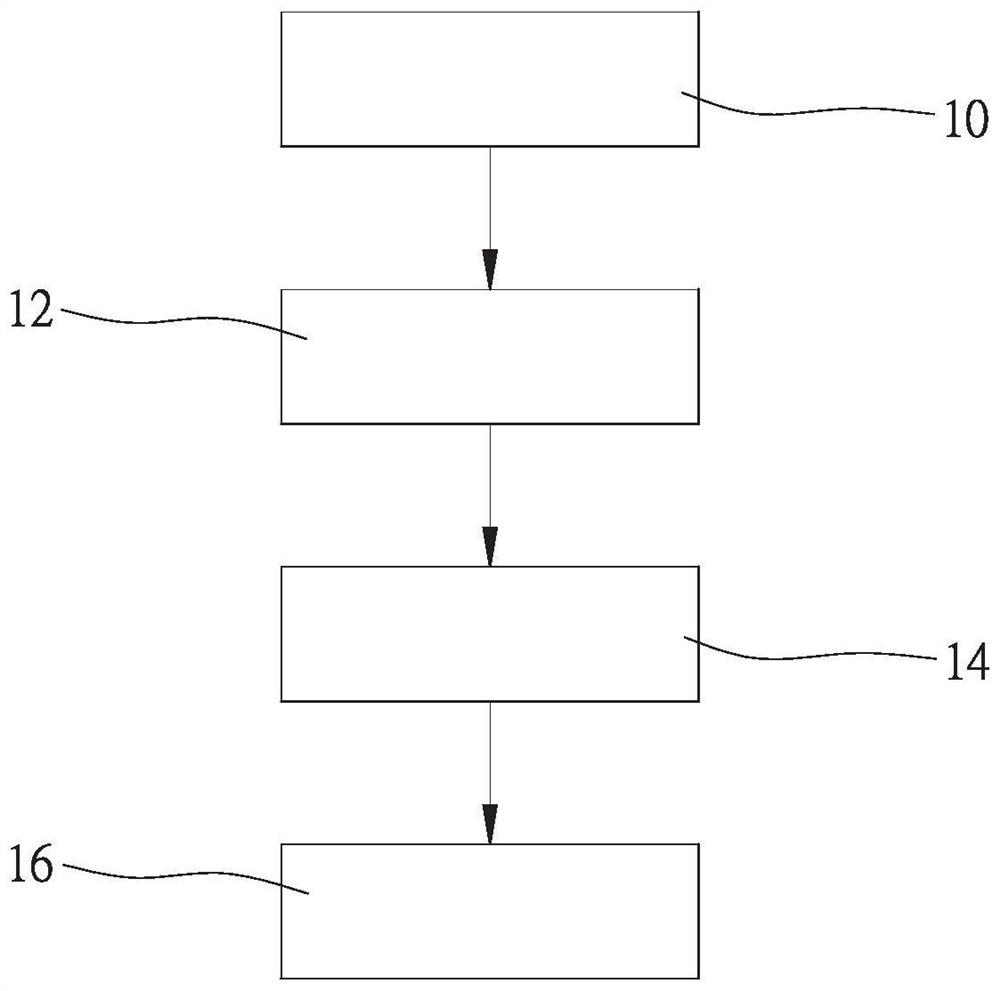

[0033] figure 1 It is a flow chart. Step 10, step 2 12, step 3 14 to step 4 16 are executed to manufacture a light-emitting device in the present invention.

[0034] Wherein, step 10 refers to: a driver integrated circuit wafer is equipped with multiple control circuits.

[0035] Step 2 12 refers to three micro-LEDs that emit red, green and blue light as a group when electrified, multiple groups of micro-LEDs are stacked on the driver integrated circuit wafer, and are electrically connected to the corresponding control circuit for packaging.

[0036] Step 3 14 refers to: the packaged driver IC wafer is laser cut into multiple driver ICs, and the control circuit of the driver ICs is electrically connected to a single group of micro LEDs to form a pixel unit in a 3D package stack structure.

[0037] As for step 4 16: multiple pixel units are transferred to the electronic circuits of the single display substrate to be connected in series to form a single-chip light emitting devi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com