A kind of pulse hydraulic fracturing coal seam pressure relief and permeation enhancement device and pressure relief and permeation enhancement method

A technology for cracking and coal seam, applied in safety devices, earth-moving drilling, wellbore/well components, etc., can solve the problems affecting gas drainage effect, gas desorption coal seam damage, loss, etc., to improve energy utilization efficiency, overcome the The effect of a lot of waste and efficient gas extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

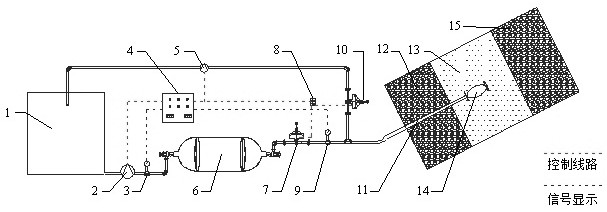

[0030] In this application, the orientation words such as upper, lower, left and right are all attached to the description. figure 1 The positional relationship in is for reference.

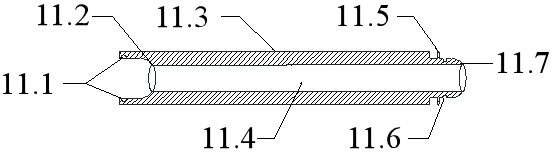

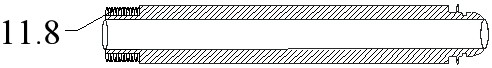

[0031] As shown in the figure, a pulse hydraulic fracturing coal seam pressure relief and permeability enhancement device includes a water tank 1, which provides a water source for a high-pressure water pump. The high-pressure water pump can pressurize the water in the water tank to form high-pressure water of 100MPa. A high-pressure water storage tank 6 connected by a pipeline, the outlet of the high-pressure water storage tank 6 is connected with a high-pressure hose through a second pipeline, the end of the high-pressure hose is provided with a delivery rod 11, and the end of the delivery rod 11 is provided with a cracker 14 , the cracker 14 is located in the coal seam 13, the top of the coal seam 13 has a top plate 15, and the bottom of the coal seam has a bottom plate 12, the first pipeline ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com