Construction method of high-fill bridge bearing platform structure

A construction method and technology for bridges, which are applied in infrastructure engineering, bridges, bridge parts, etc., can solve the problems of concentrated distributed loads and low bearing capacity of bridge caps, and achieve the goal of improving bearing capacity, ensuring construction quality, and improving stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

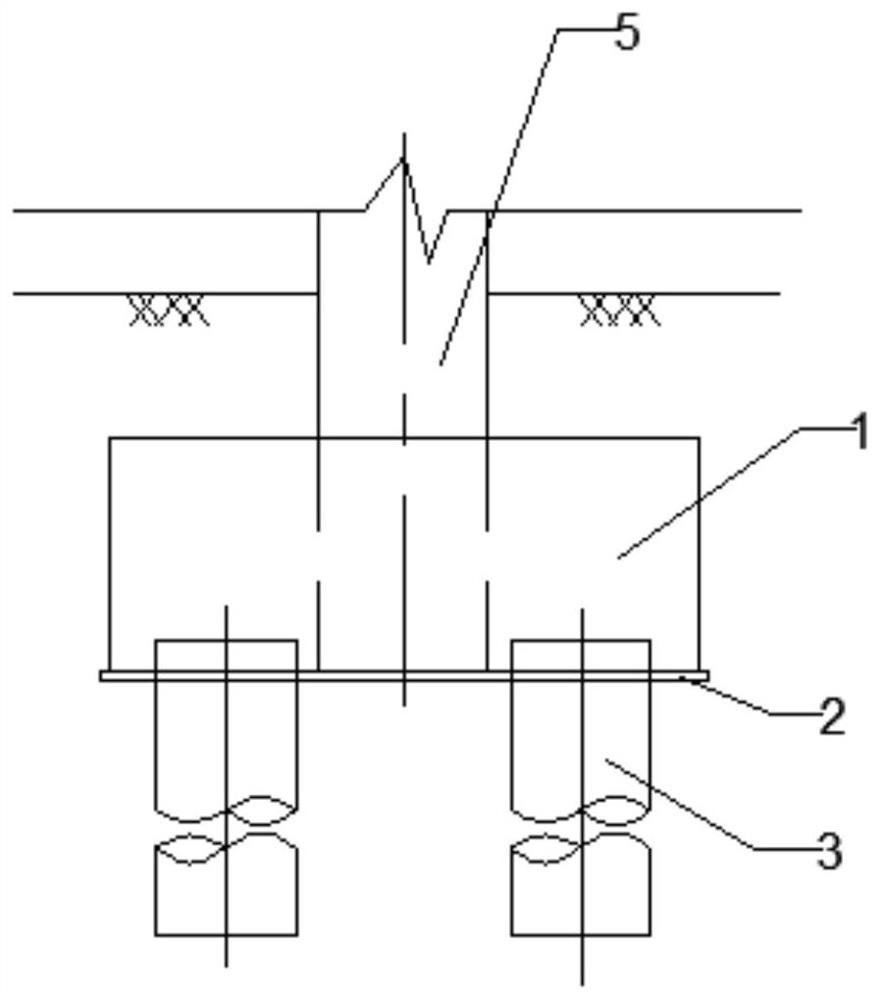

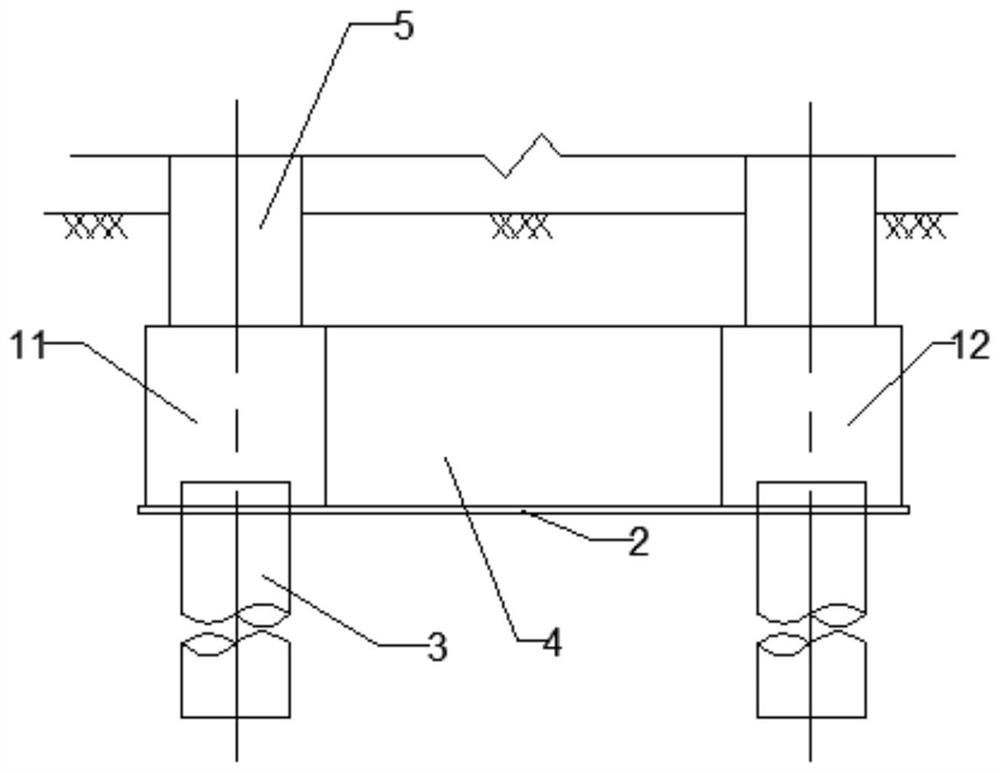

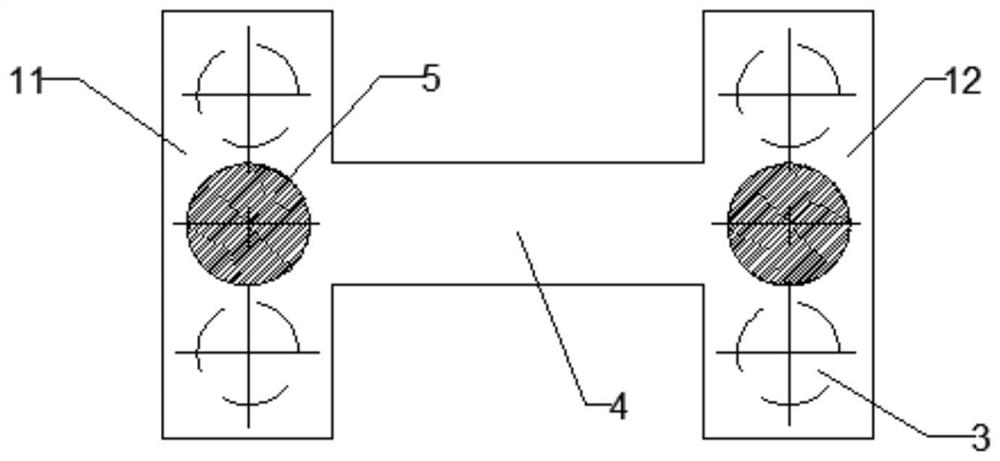

[0046] Such as figure 1 , figure 2 , image 3 As shown, the present invention provides a high-fill bridge cap structure, the high-fill bridge cap structure includes: bridge cap 1, cushion layer 2, pile foundation 3, cap tie beam 4 and pier column 5 ; The bridge cap 1, the pile foundation 3, the cap tie beam 4 and the pier column 5 are steel-concrete structures with a steel skeleton inside; the pile foundation 3 includes two or more pile columns, and each of the The top of each pile extends into the inside of the bridge cap 1; a cushion layer 2 is arranged between the bottom of the bridge cap 1 and the base, and a pier 5 is arranged on the top of the bridge cap 1, and the pier 5 is arranged on the top of the bridge cap 1. 5 includes two or more columns, and the bottom reinforcement of each column is embedded in the bridge cap 1; the bridge cap 1 includes a first cap 11 and a second cap 12, and the bridge cap A cushion layer 2 is provided between the bottom of 1 and the base...

Embodiment 2

[0051] Such as Figure 4 As shown, in order to adapt to the soil structure of the high fill foundation, further increase the stability of the bridge, and improve the safety of the bridge, on the basis of Embodiment 1, a third cap 13 is added on the right side of the second cap 12 , a cap tie beam 4 is connected between the second cap 12 and the third cap 13, and a pier column 5 is connected to the center of the top surface of the third cap 13, so that the bridge cap structure is suitable for three columns or more The column piers can improve the capacity of the bridge cap to bear and distribute the load, avoid local subsidence of the high fill foundation soil, and improve the safety of the bridge.

[0052] The invention provides a construction method for a high-fill bridge cap structure, such as Figure 5 Shown, described high fill bridge cap structure construction method comprises the following steps:

[0053] excavation pit

[0054] Before excavating the foundation pit, m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com