Manufacturing method of thermo-sensitive color-changing spun yarn

A heat-sensitive discoloration and manufacturing method technology, which is applied in rayon manufacturing, hollow filament manufacturing, melt spinning, etc., can solve the problems that will affect the air permeability and softness of fibers, the loss of discoloration performance of fabrics, increase the mixing ratio of raw materials, and process Problems such as the difficulty of parameter adjustment to achieve the effects of avoiding adhesion, increasing permeability, and fast drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for manufacturing thermosensitive color-changing spinning, comprising the following manufacturing steps:

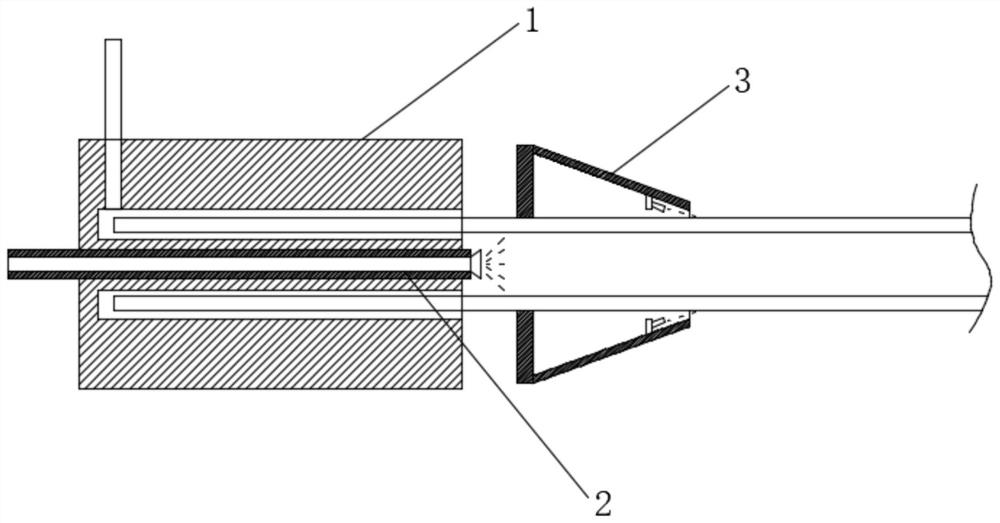

[0028] S1. Mixing polyester and corn fiber polymers in a mass ratio of 5:5, melt spinning with hollow spinneret 1 when melting to 255-260° C., to obtain hollow fibers;

[0029] S2, when the hollow spinneret 1 is spinning, the inner nozzle 2 arranged at the center of the hollow spinneret 1 and the outer nozzle 3 arranged at the outer surface of the hollow spinneret 1 are respectively used on the inner and outer walls of the hollow fiber to heat-sensitive The mixture of reversible discoloration microcapsules and ethanol vapor is sprayed, and the mixture sprayed from the inner nozzle 2 is sprayed to the inner wall of the hollow fiber in the shape of a trumpet, and the mixture sprayed from the outer nozzle 3 is sprayed to the outer wall of the hollow fiber in a conical shape. After stretching and setting Obtain hollow heat-sensitive color-changing yarn, see fo...

Embodiment 2

[0032] A method for manufacturing thermosensitive color-changing spinning, comprising the following manufacturing steps:

[0033] S1. Mixing polyester and corn fiber polymers in a mass ratio of 6:4, melt spinning with hollow spinneret 1 when melting to 255-260° C., to obtain hollow fibers;

[0034] S2, when the hollow spinneret 1 is spinning, the inner nozzle 2 arranged at the center of the hollow spinneret 1 and the outer nozzle 3 arranged at the outer surface of the hollow spinneret 1 are respectively used on the inner and outer walls of the hollow fiber to heat-sensitive The mixture of reversible discoloration microcapsules and ethanol vapor is sprayed, and the mixture sprayed from the inner nozzle 2 is sprayed to the inner wall of the hollow fiber in the shape of a trumpet, and the mixture sprayed from the outer nozzle 3 is sprayed to the outer wall of the hollow fiber in a conical shape. After stretching and setting Obtain hollow heat-sensitive color-changing yarn; wherei...

Embodiment 3

[0037] A method for manufacturing thermosensitive color-changing spinning, comprising the following manufacturing steps:

[0038] S1. Polyester and corn fiber polymers are mixed in a mass ratio of 7:3, and when melted to 255-260° C., the hollow spinneret 1 is used for melt spinning to obtain hollow fibers;

[0039] S2, when the hollow spinneret 1 is spinning, the inner nozzle 2 arranged at the center of the hollow spinneret 1 and the outer nozzle 3 arranged at the outer surface of the hollow spinneret 1 are respectively used on the inner and outer walls of the hollow fiber to heat-sensitive The mixture of reversible discoloration microcapsules and ethanol vapor is sprayed, and the mixture sprayed from the inner spray head 2 is sprayed to the inner wall of the hollow fiber in the shape of a trumpet, and the mixture sprayed from the outer spray head 3 is sprayed to the outer wall of the hollow fiber in a conical shape. After stretching and setting Obtain hollow heat-sensitive co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com