Efficient pre-oxidation equipment for general-grade asphalt-based non-woven felt

A pitch-based, non-woven felt technology, applied in the direction of textiles, papermaking, fiber chemical characteristics, etc., can solve the problems of poor pre-oxidation effect of PAN-based carbon fiber pre-oxidation furnace, and achieve the effect of improving pre-oxidation efficiency and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

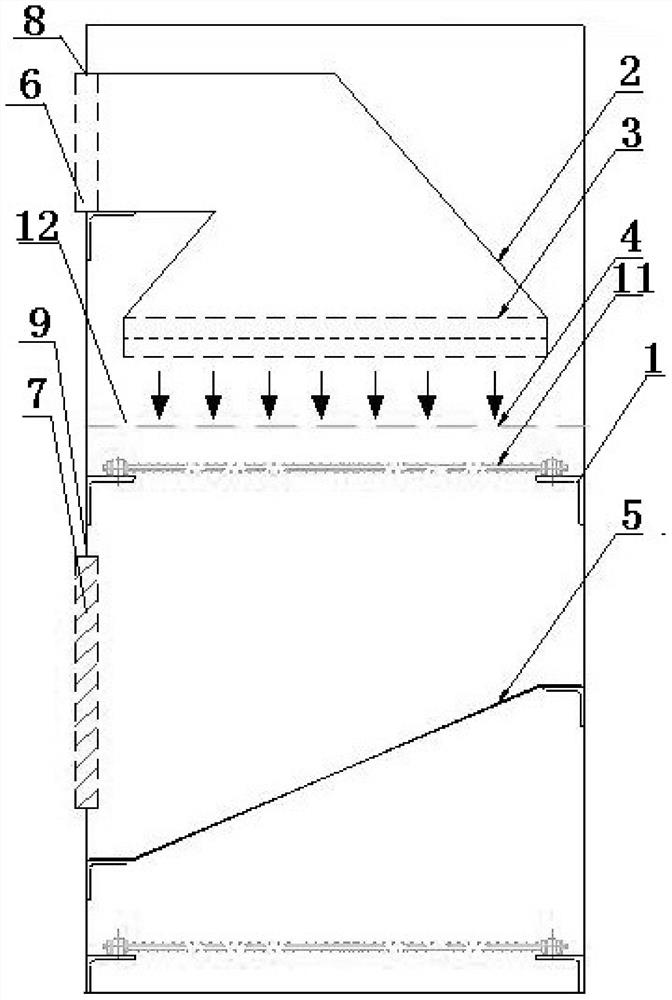

[0023] as attached figure 1 As shown, a pre-oxidation equipment for general-purpose asphalt-based non-woven felt, a pre-oxidation furnace in which hot air circulates from bottom to top, includes a pre-oxidation furnace body, and an air inlet 8 and an air outlet 9 are fixedly installed on the pre-oxidation furnace body. Enter the pre-oxidation furnace body from the air inlet, and discharge from the air outlet of the pre-oxidation furnace body.

[0024] The body of the pre-oxidation furnace includes a furnace body 1, a wind hood 2 fixedly installed on the top of the furnace body, a distribution plate 3 fixedly installed at the lower end of the wind hood, a wire pressing plate 4 fixedly installed under the distribution plate 3, and a wire pressing plate 4 fixedly installed on the bottom of the wire pressing The mesh chain device below the plate 4, the windshield 5 fixedly installed at the inner bottom of the furnace body 1, the perforated plate 6 fixedly installed at the air inle...

no. 2 example

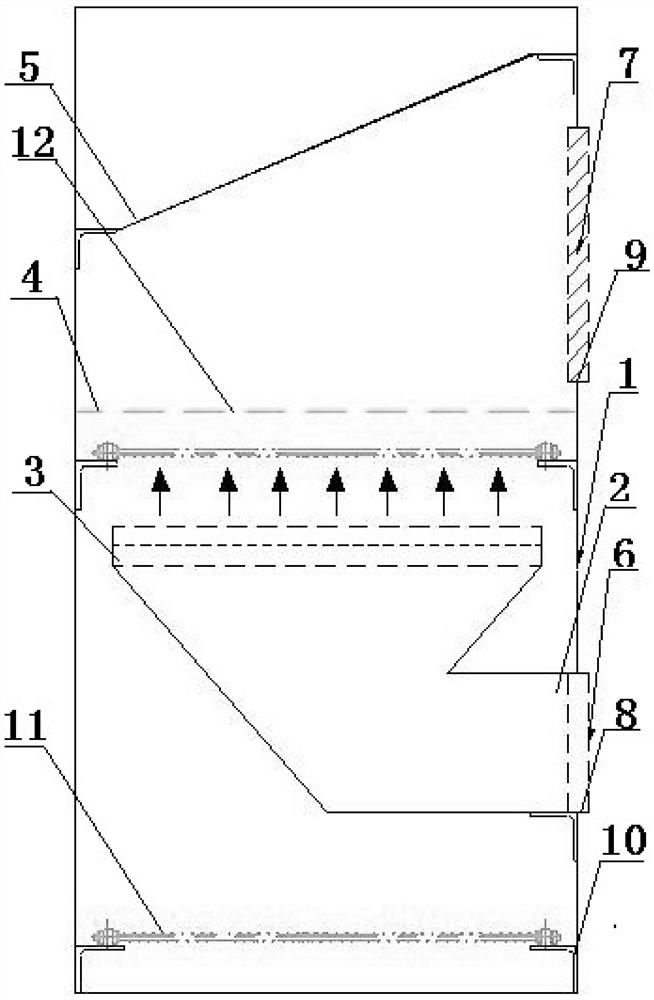

[0035] as attached figure 2 As shown, the second embodiment of the present invention is similar to the first embodiment except for the following design changes. A pre-oxidation equipment for general-purpose asphalt-based non-woven felt, a pre-oxidation furnace in which hot air circulates from top to bottom, including a pre-oxidation furnace body, and an air inlet 8, an air outlet 9, and an air inlet 8 are fixedly installed on the pre-oxidation furnace body It is fixedly installed on the top of the side wall of the furnace body 1, and the air outlet 9 is fixedly installed on the bottom end of the side wall of the furnace body 1.

[0036] The body of the pre-oxidation furnace includes a furnace body 1, a windshield 2 fixedly installed at the bottom of the furnace body, a distribution plate 3 fixedly installed at the bottom of the windshield, a wire pressing plate 4 fixedly installed above the distribution plate 3, and a wire pressing plate fixedly installed on the bottom of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com