Calcium phosphate biological ceramic with superfine uniform crystal grains and preparation method of calcium phosphate biological ceramic

A technology of bioceramics and uniform grains, which can be used in drug delivery, tissue regeneration, and pharmaceutical formulations. It can solve the problems of poor mechanical properties of calcium phosphate bioceramics, and achieve excellent mechanical properties, optimized mechanical properties, and scientific design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

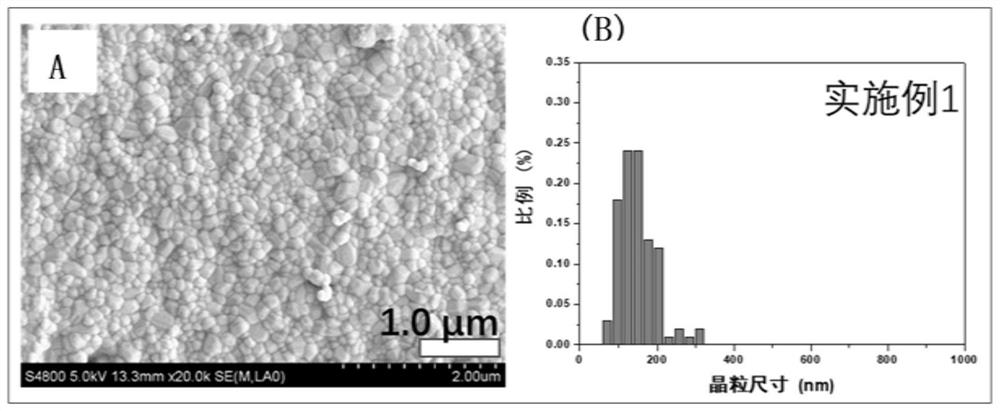

[0043] This embodiment discloses the preparation method of the calcium phosphate bioceramics of ultrafine uniform grains of the present invention, specifically:

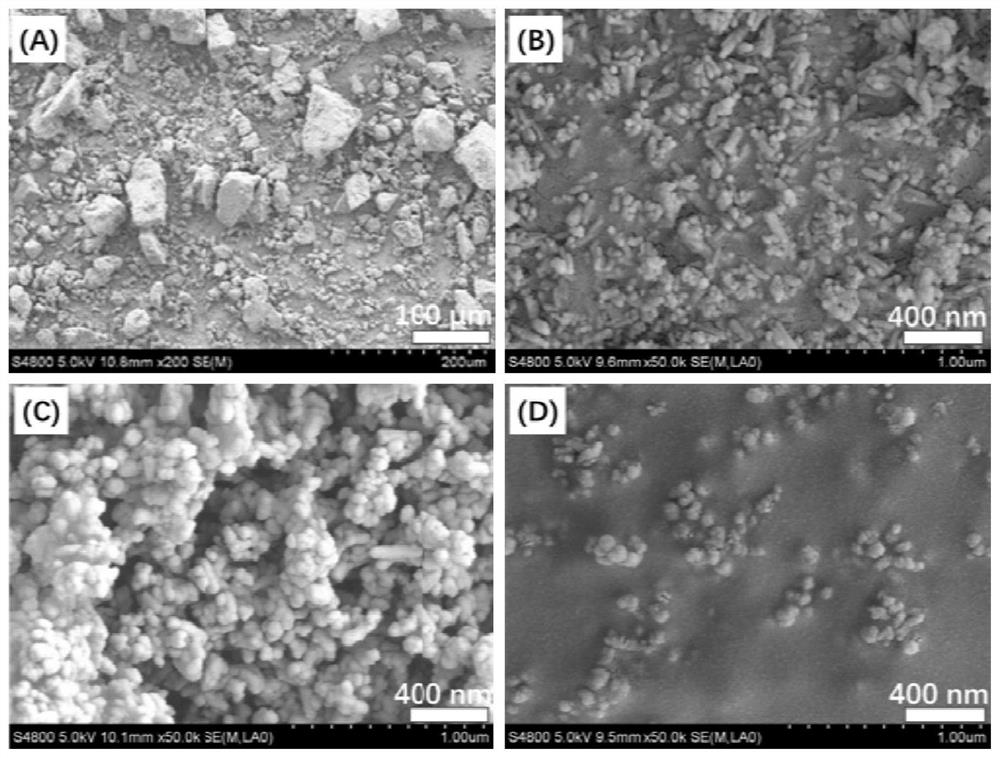

[0044] (1) Weigh 6g of primary hydroxyapatite powder (HA), and pre-sinter it at a low temperature at 600°C for 4 hours to obtain the pre-sintered powder and the microscopic morphology of the primary hydroxyapatite powder as attached figure 1 As shown in A.

[0045] (2) The calcined powder is subjected to wet ball milling, the medium is absolute ethanol, the volume is 50mL, the ball milling speed is 450rpm, and the ball milling time is 14h; the slurry after ball milling is centrifuged at 5000rpm for 5min, and then the centrifuged The supernatant was centrifuged for a second time at 10,000rpm for 5 minutes, and the supernatant obtained from the second centrifugation was centrifuged at 12,000rpm for 5 minutes, and the precipitate was collected, dried, ground and sieved to obtain phosphoric acid with small grain size an...

Embodiment 2

[0052] In this embodiment, whether low-temperature pre-sintering and the temperature of low-temperature pre-sintering are investigated: when low-temperature pre-sintering is not used, compared with Example 1, there is no step (1), and the rest of the conditions are the same; different pre-sintering temperatures are used , the pre-sintering temperature is as shown in the table below, and all the other conditions are the same as in Example 1.

[0053] Table 1 Pre-sintering temperature investigation results table

[0054]

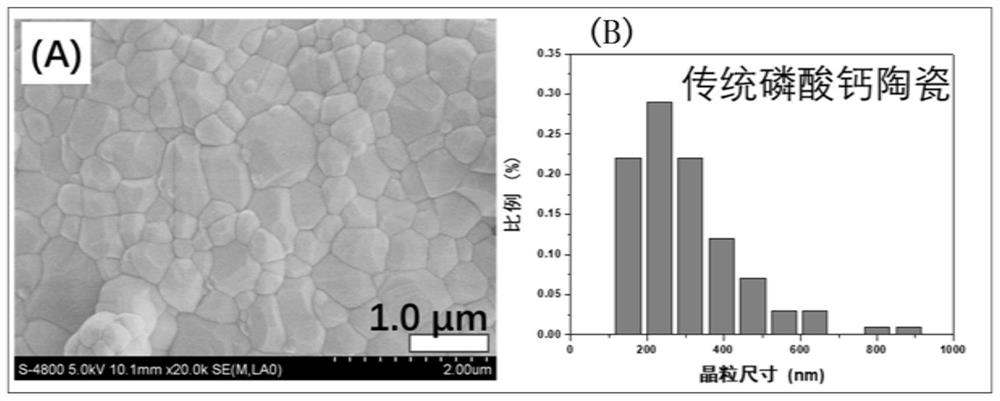

[0055] It can be seen from the above table that when the pre-sintering temperature is 600-900°C, the obtained calcium phosphate bioceramic has a small average grain size, narrow distribution, good compressive strength, and good compressive strength.

[0056] The micro-morphology of the calcium phosphate powder prepared at the pre-sintering temperature of 700 °C is shown in the attached figure 1 As shown in C, compared with the unoptimized calcium phosphate...

Embodiment 3

[0060] This embodiment investigates whether to quench and different quenching methods: when not quenching, in the two-step sintering, after the second step of sintering and heat preservation, cool with the furnace, and the rest of the conditions are the same as in Example 1; when using different quenching methods , concrete quenching conditions are as shown in the table below, and all the other conditions are with embodiment 1:

[0061] Table 2 Quenching method investigation results table

[0062]

[0063]

[0064] It can be seen from the above table that the quenching method of the present invention is better than quenching and cooling in stages, and is better than cooling with furnace without quenching.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com