Rigid push chain drive system

A technology of rigid push chain and drive system, which is applied in the field of mechanical transmission, can solve the problems of high manufacturing cost, interference, and various types of parts, and achieve the effects of ensuring safety and reliability, reducing the space occupied by the level, and improving the level of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

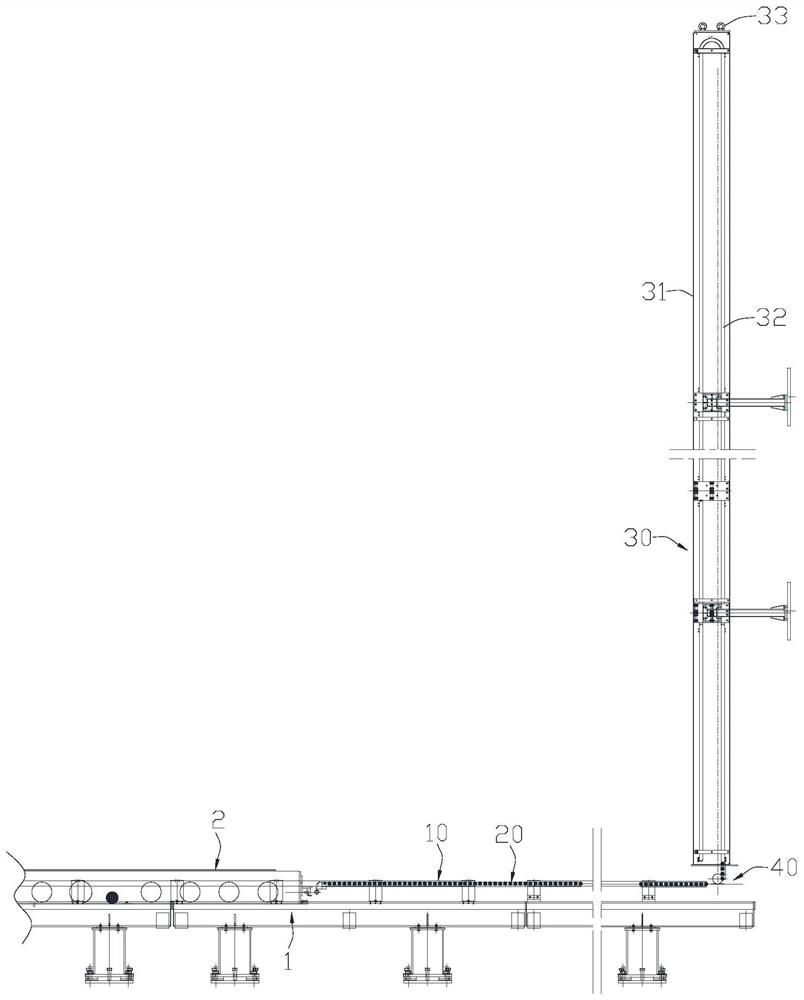

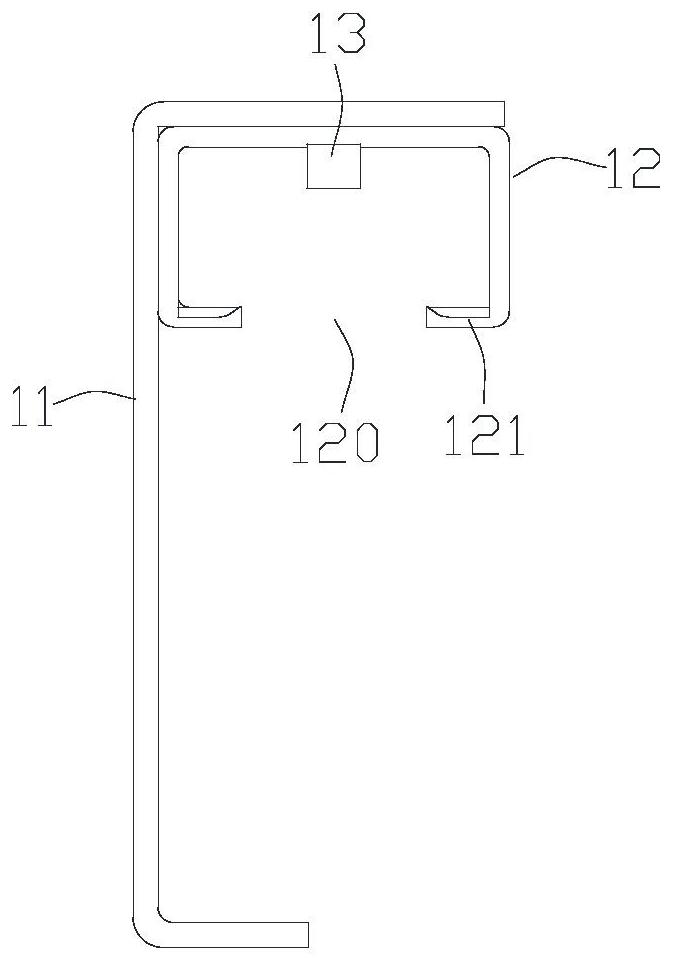

[0037] Such as figure 1 As shown, a rigid push chain drive system according to an embodiment of the present invention can be used for nuclear fuel transfer, and it can include a guide rail 10 , a rigid push chain 20 , a chain storage mechanism 30 and a sprocket mechanism 40 .

[0038] One end of the guide rail 10 is connected to the transport guide rail 1 , so that the transport trolley 2 can travel from the transport guide rail 1 to the guide rail 10 . The rigid push chain 20 is arranged in the guide rail 10 and fixedly connected with the transport trolley 2. The rigid push chain 20 can move back and forth along the axial direction of the guide rail 10, thereby pushing and pulling the transport trolley 2 to realize the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com