Efficient chemical reaction kettle

A chemical reaction and reaction kettle technology, which is applied in chemical instruments and methods, chemical/physical processes, chemical/physical/physical chemical processes, etc. Prevent the spread of toxic gases, improve work and experimental efficiency, and ensure the effect of experimental safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

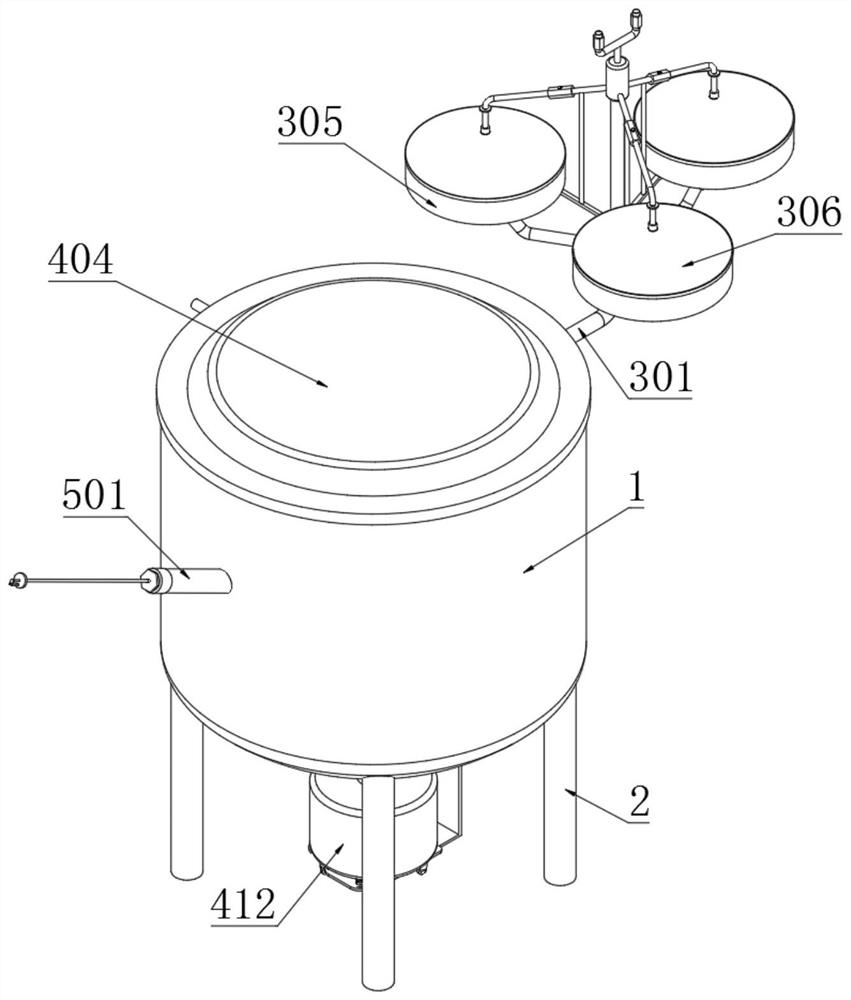

[0040] Example: such as Figure 1-9 As shown, the present invention provides a technical solution, a high-efficiency chemical reactor, comprising a reactor tank 1, a support leg 2 is welded to the bottom of the reactor tank 1, and a feeding assembly 3 is installed on one side end of the reactor tank 1 , the inside of the reactor tank 1 is equipped with a waste treatment assembly 4, and the outside of the reactor tank 1 is equipped with a sampling assembly 5;

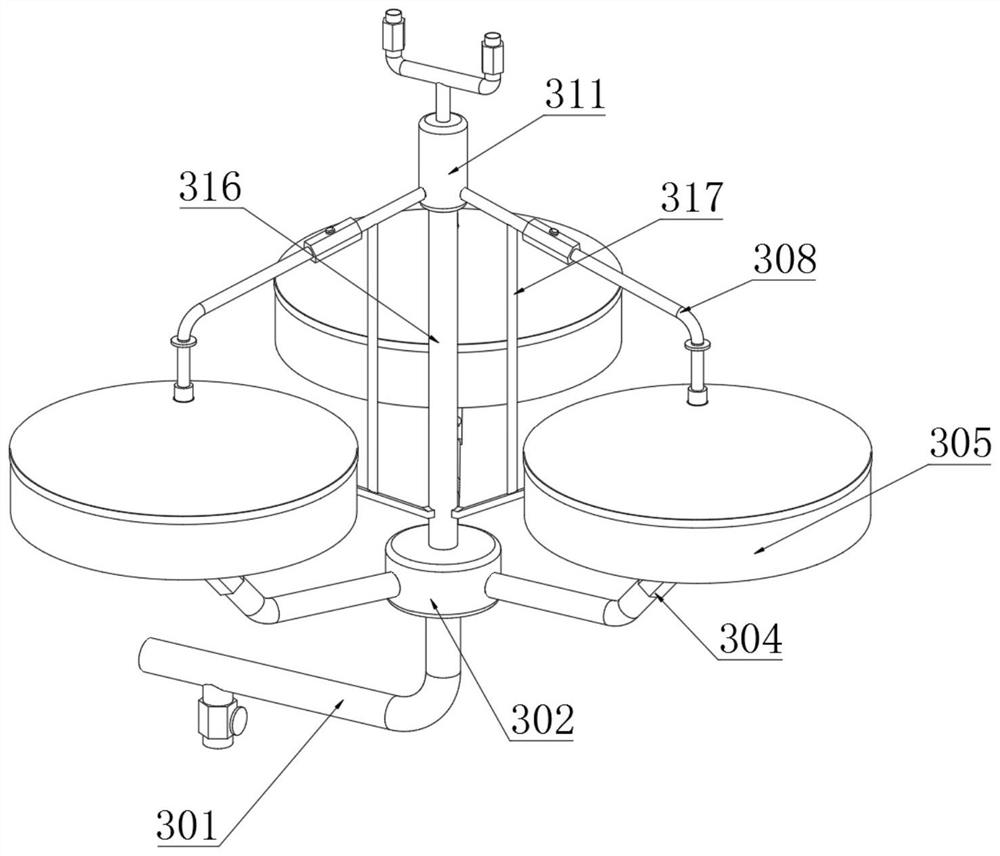

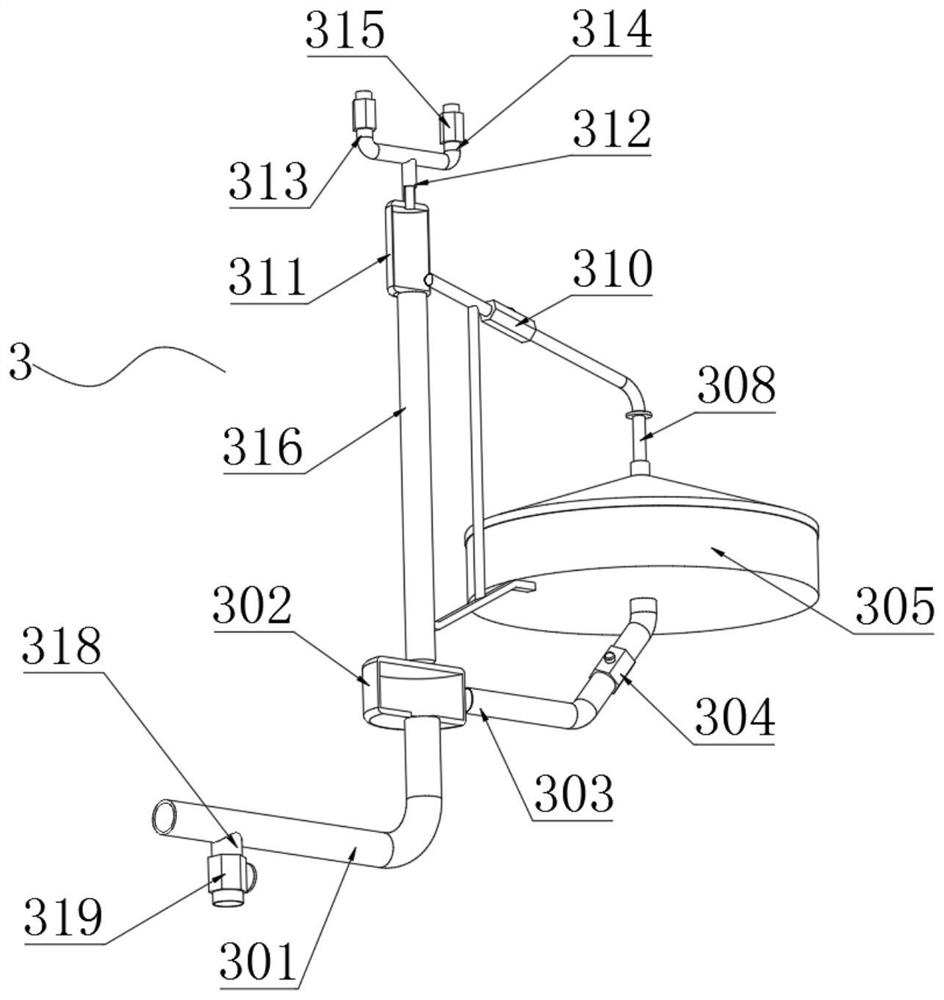

[0041] Feeding assembly 3 comprises feeding pipe 301, collecting box 302, collecting pipe 303, bottom control valve 304, raw material box 305, airtight screw cap 306, sealing ring 307, injection pipe 308, magnet 309, top control valve 310, Air collecting barrel 311, diversion pipe 312, water inlet pipe 313, air inlet pipe 314, flow valve 315, support rod 316, support frame 317, drain pipe 318 and manual valve 319;

[0042] The outside of the reactor tank 1 is connected with a feed pipe 301, and the outside of the reacto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com