Heat dissipation type anti-seismic aluminum electrolytic capacitor

An aluminum electrolytic capacitor, heat dissipation technology, applied in the field of capacitors, can solve the problems of broken needle capacitor heat, capacitor element damage, capacitor shaking, etc., to improve heat dissipation performance, avoid vibration problems, and improve service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

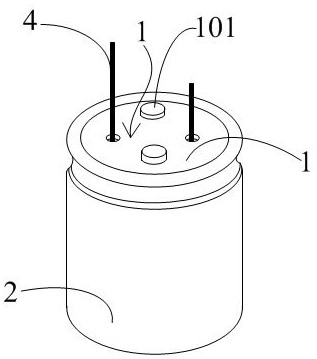

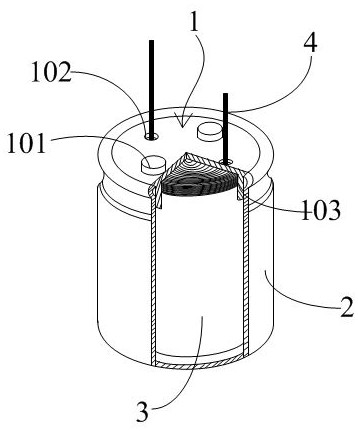

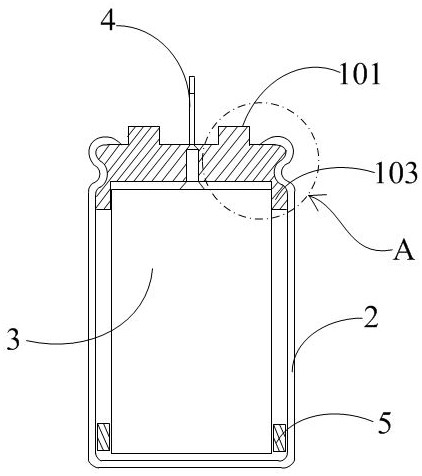

[0041]In this embodiment, the protrusions 101 are evenly distributed along the circumferential direction of the upper end surface of the cover plate 1 , and the number of the protrusions 101 is two. The height of the protrusions 101 is 3nm. The section of the protrusion 101 is circular. The upper end surface of the cover plate 1 is provided with a protrusion 101 symmetrically with the center of the cover plate 1, and a wall portion 103 is arranged on the circumferential direction of the lower end surface of the cover plate 1; The diameter of the outer circumference matches that of the outer circumference; the outer circumference of the wall 103 is in conflict with the inner circumference of the housing 2; One end of the element 3 connected with the lead wire 4 is sleeved and fixed in the wall 103 to form a whole. The end of the element 3 away from the cover plate 1 is sleeved with a ring member 5 . The height of the protrusion 101 is greater than that of the plain waist 104...

Embodiment 2

[0045] In this embodiment, the protrusions 101 are evenly distributed along the circumferential direction of the upper end surface of the cover plate 1, as Figure 5 As shown, the number of the protrusions 101 is four. The height of the protrusions 101 is 2nm. The section of the protrusion 101 is circular. The upper end surface of the cover plate 1 is provided with a protrusion 101 symmetrically with the center of the cover plate 1, and a wall portion 103 is arranged on the circumferential direction of the lower end surface of the cover plate 1; The diameter of the outer circumference matches that of the outer circumference; the outer circumference of the wall 103 is in conflict with the inner circumference of the housing 2; One end of the element 3 connected with the lead wire 4 is sleeved and fixed in the wall 103 to form a whole. The end of the element 3 away from the cover plate 1 is sleeved with a ring member 5 . The height of the protrusion 101 is greater than that o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com