Spinning bobbin replacement device capable of avoiding shutdown and replacement method of spinning bobbin replacement device

A textile thread and bobbin technology, which is applied in the field of textile bobbin replacement devices, can solve problems such as textile bobbin monitoring, increase device cost, and affect textile thread replenishment, and achieve the effects of reducing labor intensity, ensuring efficiency, and improving practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

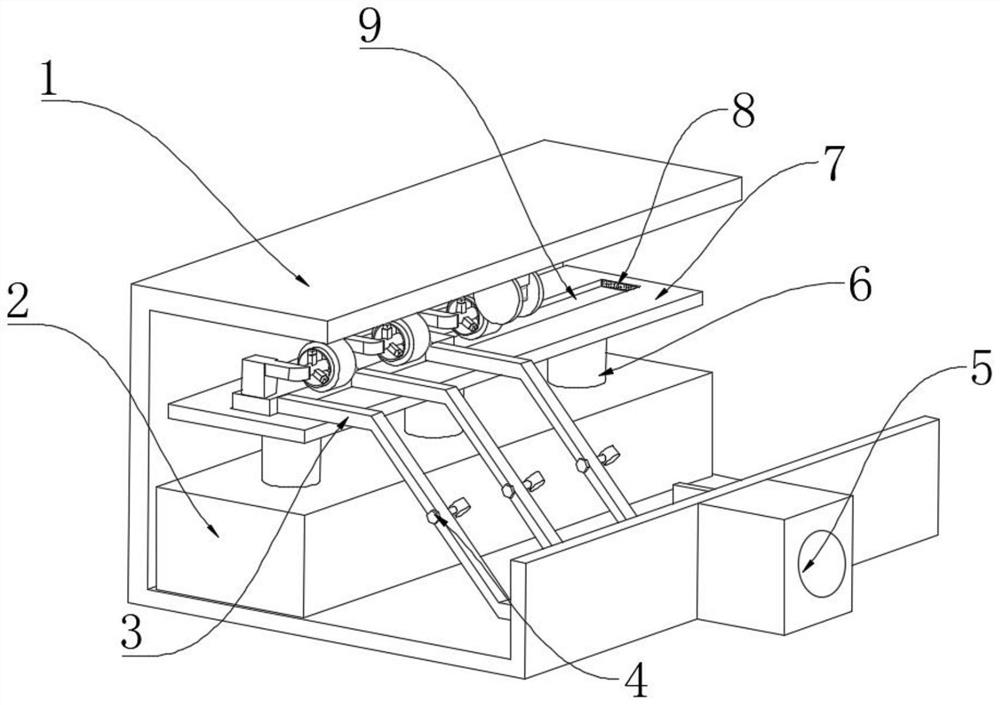

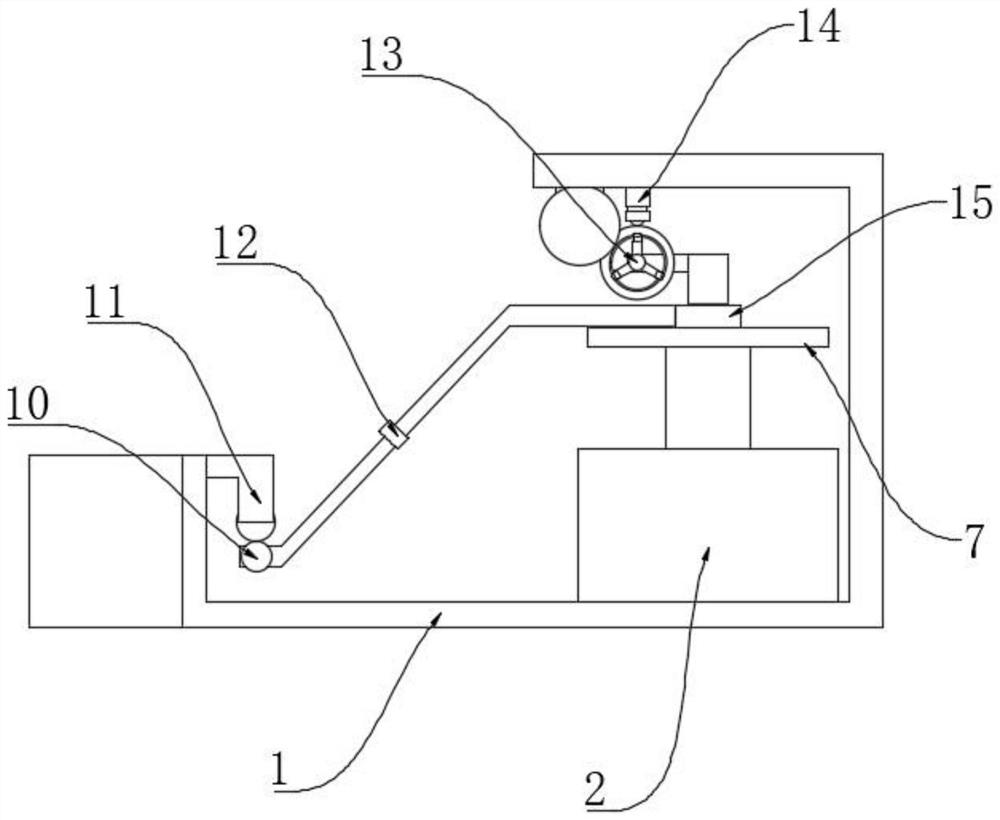

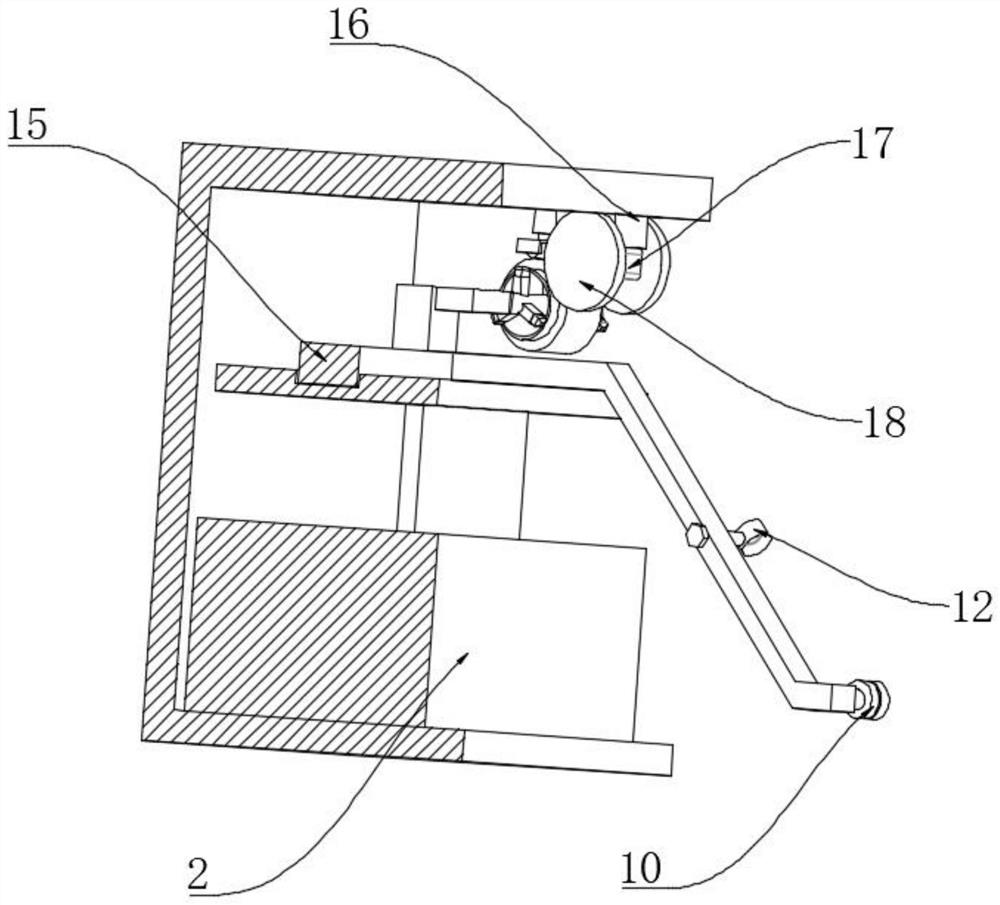

[0038] A textile bobbin changing device that avoids downtime such as figure 1 , figure 2 , Figure 4As shown, it includes a working frame 1 and a spinning spool 19; the inner wall at the bottom of the working frame 1 is fixedly connected with a hydraulic cylinder 2; the inner wall at the top of the hydraulic cylinder 2 is provided with evenly distributed telescopic connecting rods 6; The outer wall is fixedly connected with a supporting connecting plate 7; the inner wall at the top of the supporting connecting plate 7 is processed with an electric guide rail 9; the inner wall on one side of the electric guiding rail 9 is slidingly connected with an electric skateboard 15; The inner wall on one side of the wire barrel 19 is rotatably connected to the outer wall around the bearing mechanism 13; the inner wall at the top of the working frame 1 is fixedly connected with a monitoring mechanism 14; the outer walls on both sides of the electric guide rail 9 are fixedly connected wi...

Embodiment 2

[0045] A replacement method for a textile bobbin replacement device that avoids downtime, specifically comprising the following steps:

[0046] S1: pass the textile thread on the textile thread cylinder 19 respectively through the corresponding limit ring 12 and place it on the support roller 10, and sprinkle water on the textile thread on the support roller 10;

[0047] S2: Start the drive motor 2, and the winding roller 3 rotates to gather the textile thread;

[0048] S3: Run the fixed base 16 and the guide roller 11 to carry out traction and transmission of the textile thread;

[0049] S4: When the measuring connecting rod 1402 is lowered to the designated position, the hydraulic cylinder 2 operates to move the support connecting plate 7 downward, and the supporting plate 5 moves downward, and the textile thread spool 19 on the new carrying mechanism 13 is moved to the working position;

[0050] S5: When the electric skateboard 15 moves to the edge position of the electric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com