Nickel phosphide composite electrode and preparation method and application thereof

A composite electrode, nickel phosphide technology, used in hybrid capacitor electrodes, hybrid/electric double layer capacitor manufacturing, battery electrodes, etc., can solve the problems of reducing the bonding force at the interface of materials, discounting electrode cycle life, and difficult to industrialize applications. Achieve controllable balance of conductivity and capacity, good cycle performance, and firm adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] Based on the same inventive concept, the embodiment of the present application also provides a method for preparing the above-mentioned nickel phosphide composite electrode, comprising the following steps:

[0033] S1. Prepare a mixed solution containing nickel salt, triton and reducing agent, then heat it to 55-65° C., heat up to 66-75° C. after the reaction, and continue the reaction to obtain a nickel hydroxide nanosheet / nickel nanowire precursor;

[0034] S2. Put the nickel hydroxide nanosheet / nickel nanowire precursor and the phosphating additive in a tube furnace, raise the temperature to 300-400° C. under a protective atmosphere, and obtain the nickel phosphide composite electrode after phosphating.

[0035] It should be noted that the specific preparation method of the mixed solution of this application is: add nickel salt, triton and reducing agent to water, and stir evenly to obtain the mixed solution; the nickel hydroxide nanosheet / nickel nanowire precursor in...

Embodiment 1

[0048] The embodiment of the present application provides a method for preparing a nickel phosphide composite electrode, comprising the following steps:

[0049] S1. Prepare a mixed solution containing nickel salt, triton and hydrazine hydrate, then heat it to 62°C, keep it warm for 30 minutes, then raise the temperature to 70°C, keep it warm until the solution is clear, collect, wash, and dry to obtain nickel hydroxide nano Sheet / nickel nanowire precursor;

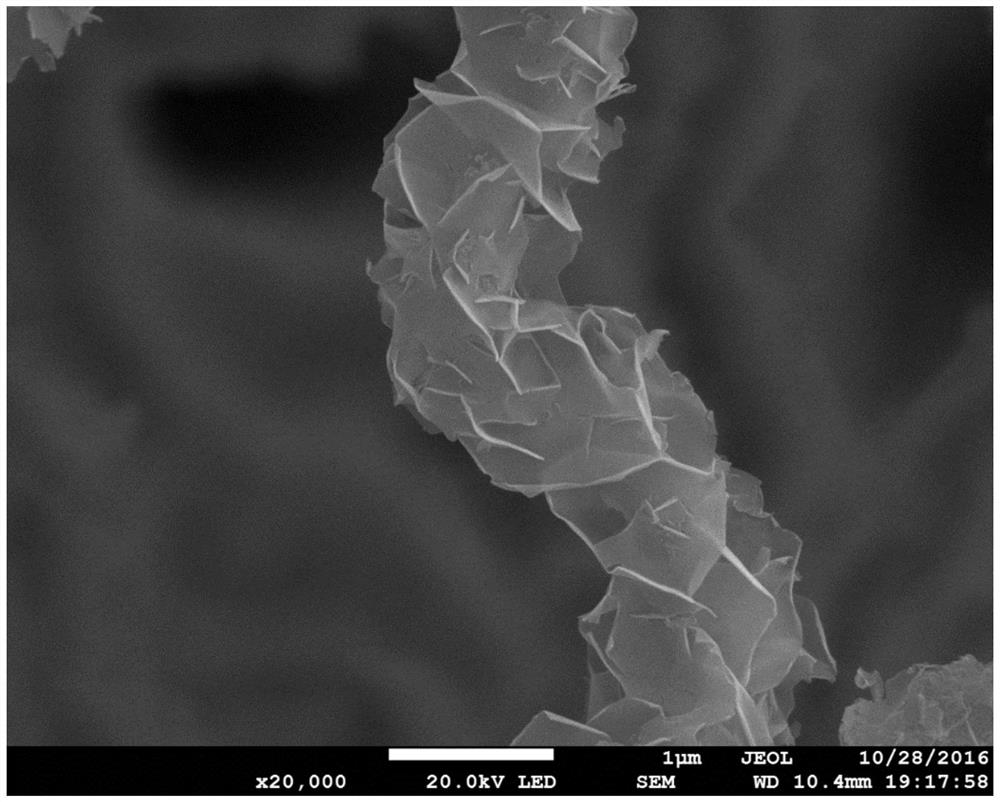

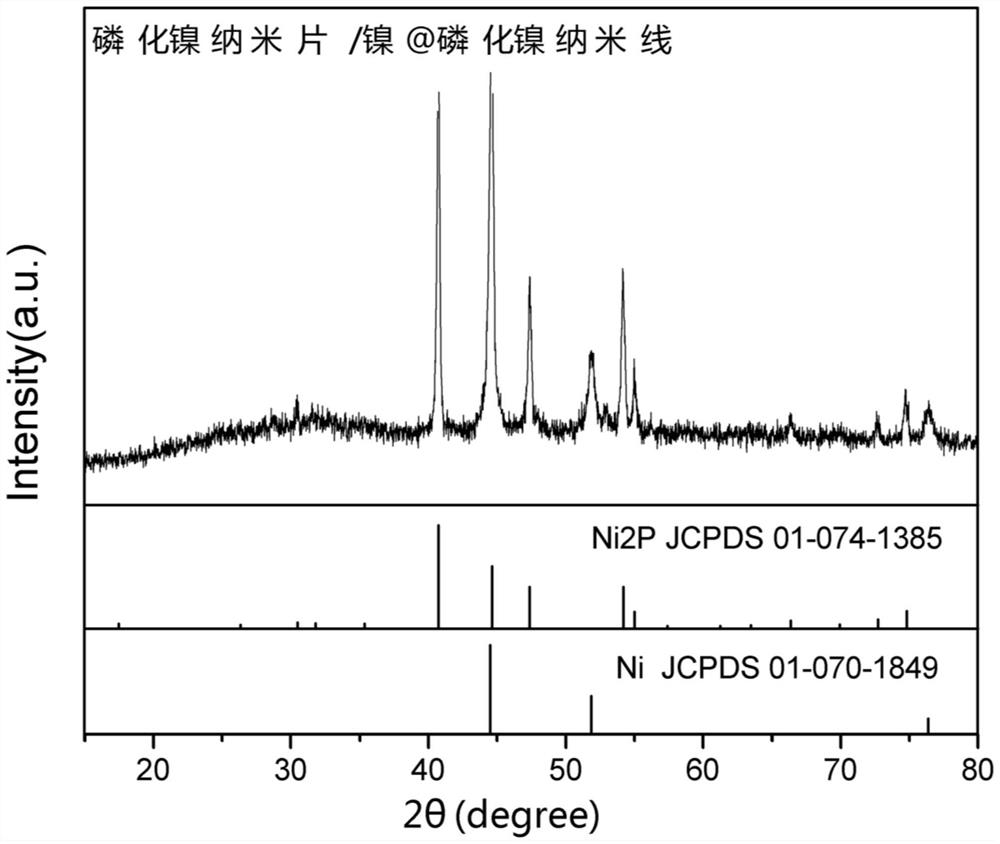

[0050] S2. Put the nickel hydroxide nanosheet / nickel nanowire precursor and excess sodium dihydrogen hypophosphite in a tube furnace, and raise the temperature to 350°C at a heating rate of 1°C / min under a hydrogen / argon mixed atmosphere, and then phosphate After annealing for 2 hours, cool to room temperature and collect samples to obtain a composite electrode of "nickel phosphide nanosheet / nickel@nickel phosphide nanowire" (that is, nickel phosphide composite electrode);

[0051] Wherein, the nickel salt in the mixed s...

Embodiment 2

[0053] The embodiment of the present application provides a method for preparing a nickel phosphide composite electrode, comprising the following steps:

[0054] S1. Prepare a mixed solution containing nickel salt, triton and hydrazine hydrate, then heat it to 62°C, keep it warm for 30 minutes, then raise the temperature to 70°C, keep it warm until the solution is clear, collect, wash, and dry to obtain nickel hydroxide nano Sheet / nickel nanowire precursor;

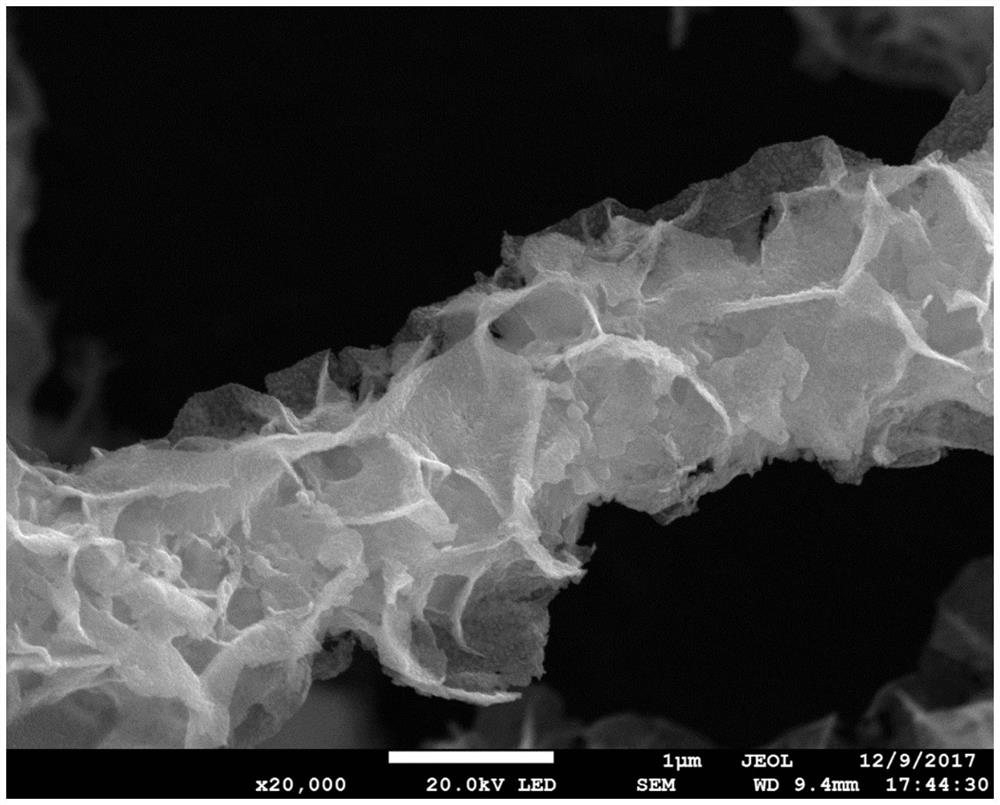

[0055] S2. Put the nickel hydroxide nanosheet / nickel nanowire precursor and excess sodium dihydrogen hypophosphite in a tube furnace, and raise the temperature to 350°C at a heating rate of 1°C / min under a hydrogen / argon mixed atmosphere, and then phosphate After annealing for 1 hour, cool to room temperature to collect the sample, and obtain the composite electrode of "nickel phosphide nanosheet / nickel@nickel phosphide nanowire" (that is, nickel phosphide composite electrode);

[0056] Wherein, the nickel salt in the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com