Fusion method of glass reinforced plastic pipe and steel flange

A kind of glass fiber reinforced plastic, glass fiber reinforced plastic technology, applied in flange connection, pipe/pipe joint/pipe fitting, through components, etc., can solve the problems of easy water leakage, incomparable with steel flange, can not be used for a long time, etc., to improve waterproof capacity, improve link strength, and improve the effect of installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

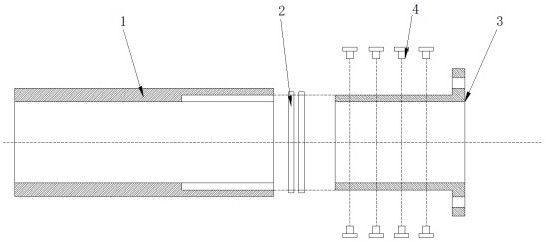

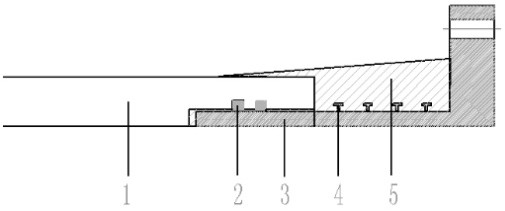

[0021] refer to Figure 1-2 , a fusion method of glass steel pipes and steel flanges, the fusion method of glass steel pipes and steel flanges consists of five parts: glass steel pipe material 1, waterproof rubber ring 2, steel flange 3, steel hook 4 and hand-laid glass fiber reinforced plastic material 5 based on the following steps:

[0022] S1: Take the fiberglass steel pipe 1 of the diameter to be connected, and grind the end of the glass steel pipe 1 so that the inner wall of the pipe end of the glass steel pipe 1 forms a pipe groove;

[0023] S2: Matching steel flange 3, the thickness of one end of steel flange 3 is required to be exactly equal to the depth of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com