Power box take-up and pay-off control system

A control system and power box technology, which is applied in the field of power boxes, can solve problems that affect work efficiency, affect smooth line release, and increase on-site safety risks, and achieve the effects of orderly arrangement, saving manpower consumption, and reducing manpower consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art are in the range of the present invention without making creative labor premise.

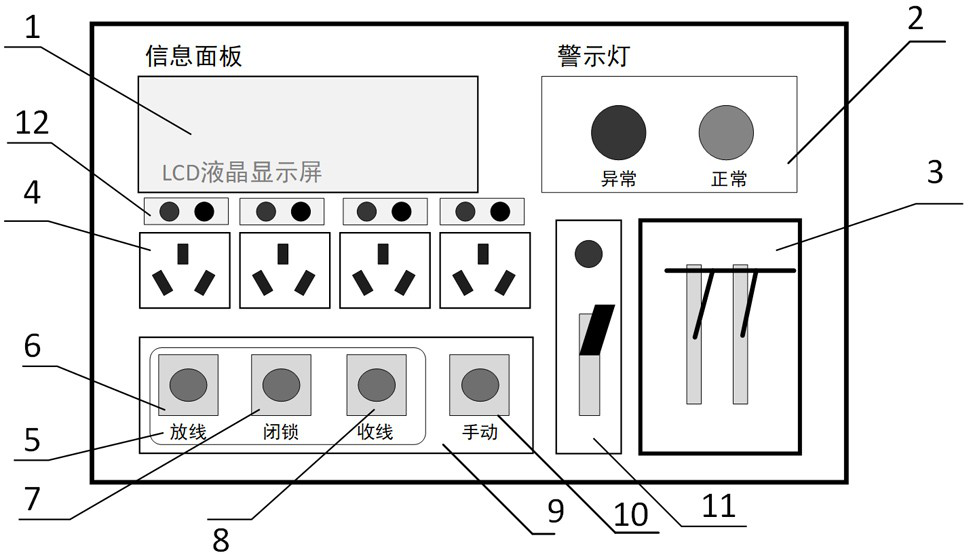

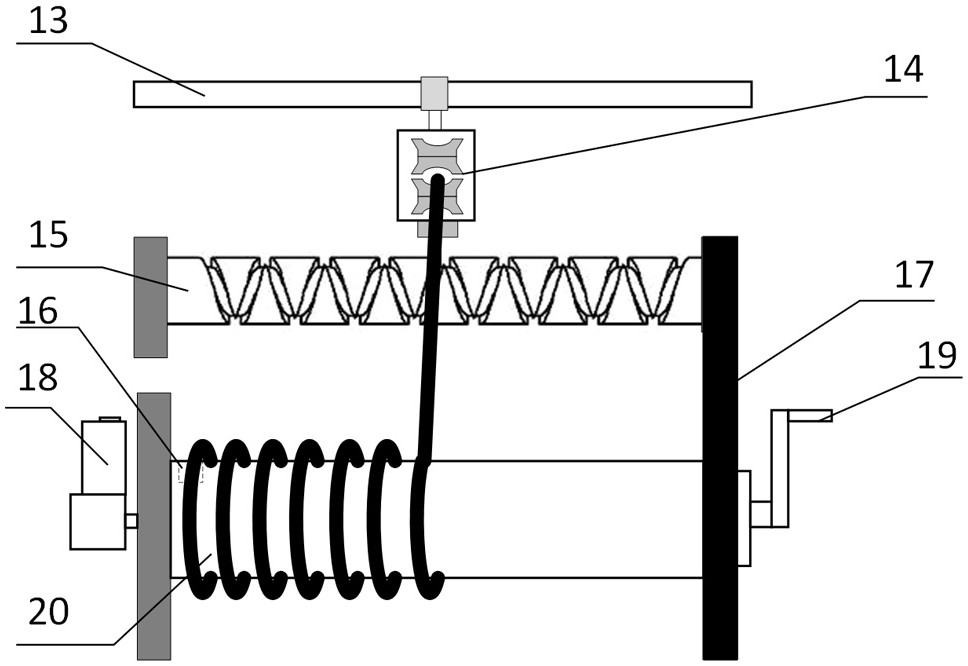

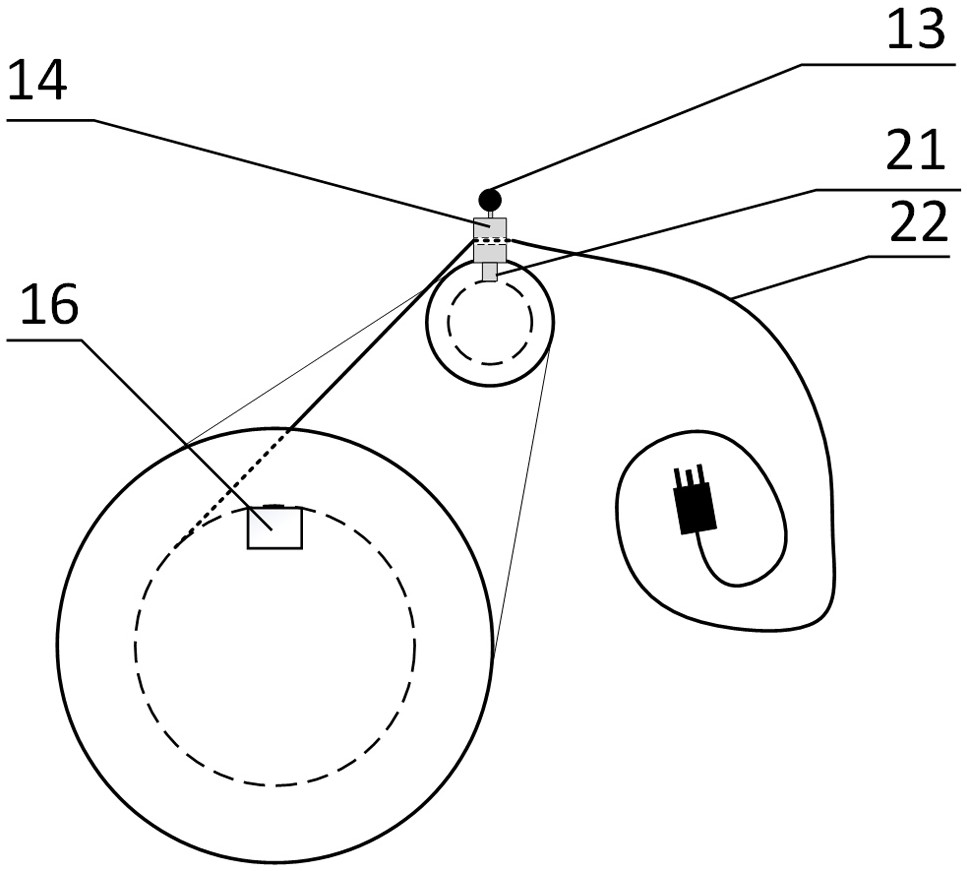

[0032] See Figure 1-5 , The retractable line control system according to the present invention, the conventional power supply box on the basis of an increase of the cable trough screw mechanism, while the reel is mounted inside the torque sensor for detecting retractable line status, control power or electric drive motor driving the retractable line control system reserve mode manually retractable lines, while increasing the reliability of detection of jamming, to avoid jamming ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com