Skipping rope handle coloring device for sporting goods processing

A technique for jumping rope handles and sporting goods, which is applied to the device for coating liquid on the surface, pretreatment surface, coating, etc., and can solve the problem of slow painting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

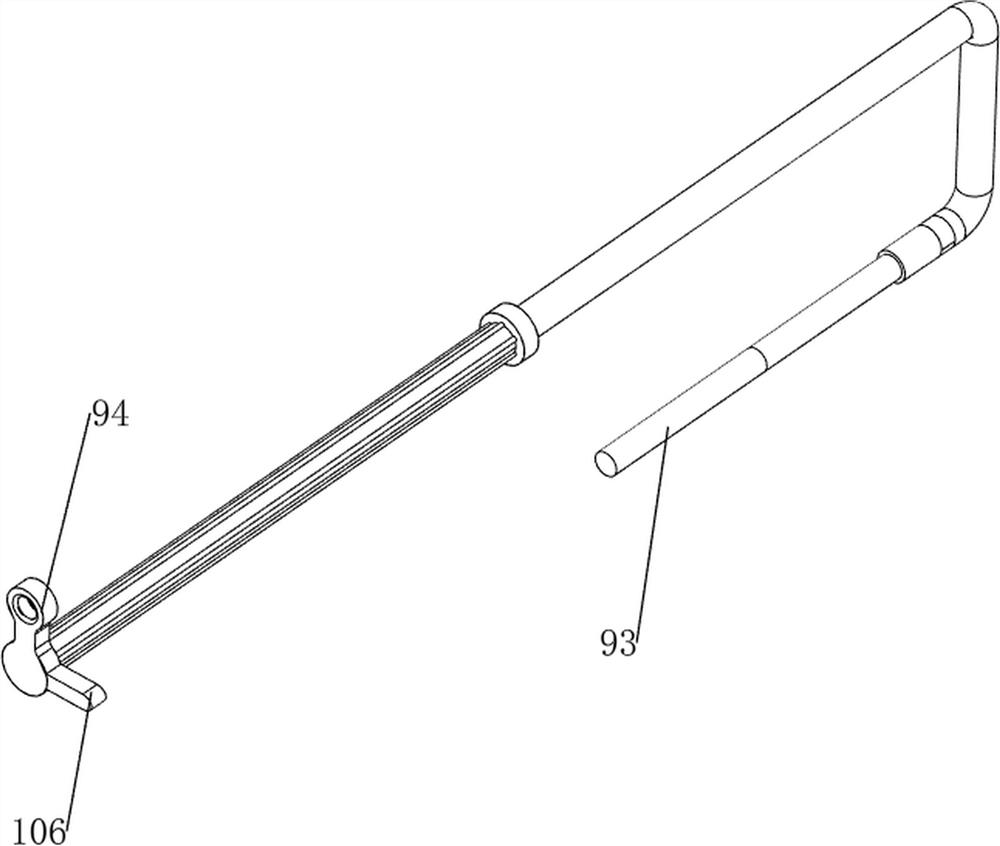

[0030] A skipping rope handle coloring device for sporting goods processing, such as Figure 1-4 As shown, it includes a support plate 1, a first support frame 2, a rotating frame 3, a first rubber 4, a motor 5, a manual rotation mechanism 6 and a clamping mechanism 7, and the left side of the top of the support plate 1 is provided with a first support frame 2 , the first supporting frame 2 is rotatably provided with a rotating frame 3, the rotating frame 3 is provided with a first rubber 4, the left side of the first supporting frame 2 is provided with a motor 5, the output shaft of the motor 5 is connected with the rotating frame 3, and the supporting plate 1. A manual rotation mechanism 6 is provided on the front side of the top, and a clamping mechanism 7 is provided on the first support frame 2. The clamping mechanism 7 is used to clamp and limit the handle.

[0031] The manual rotation mechanism 6 includes a second support frame 61, a charging frame 62, a third support f...

Embodiment 2

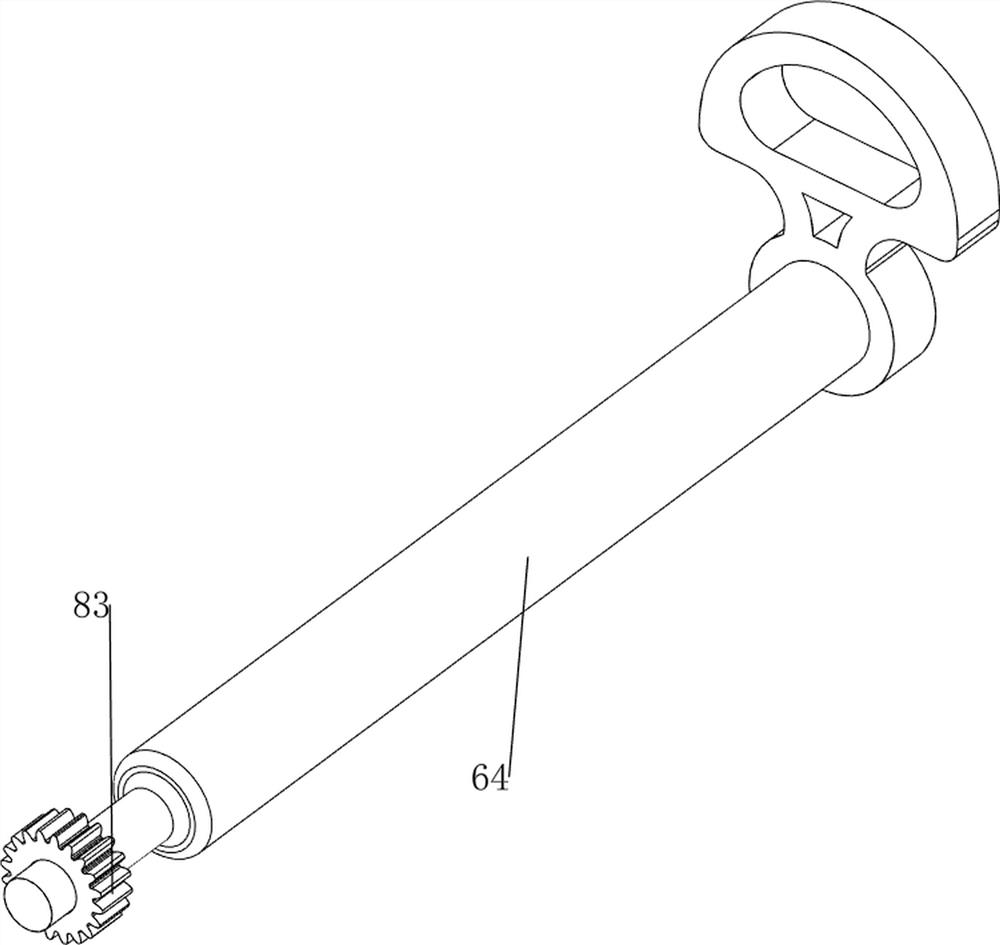

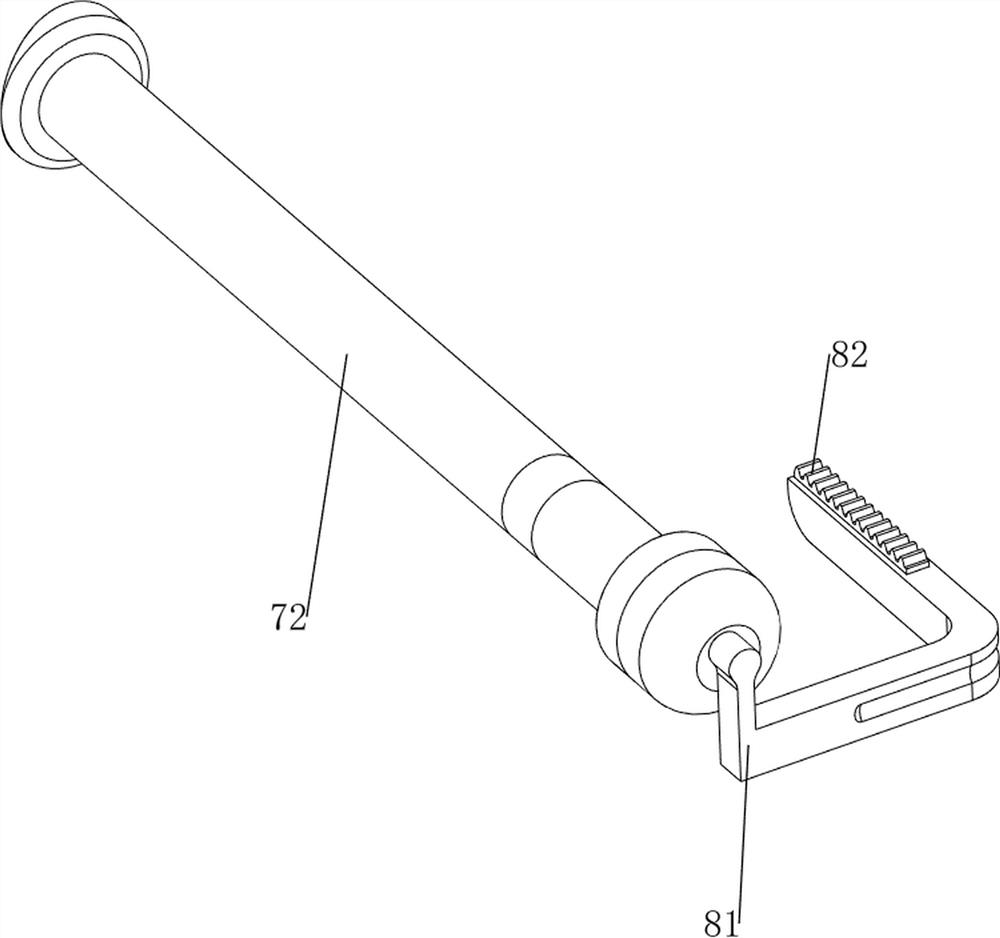

[0035] On the basis of Example 1, such as figure 1 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 As shown, it also includes an automatic rotation mechanism 8, the automatic rotation mechanism 8 includes a first bracket 81, a rack 82 and a gear 83, the movable rod 72 on the front side is provided with a first bracket 81, and the first bracket 81 is provided with a first bracket 81. The rack 82 is provided with a gear 83 on the first rotating shaft 64 , and the gear 83 meshes with the rack 82 .

[0036]The user moves the front movable rod 72 forward to drive the rack 82 to move forward, and then the movable rods 72 on both sides move to both sides for a short distance, just leaving a space to limit the handle. , the gear rack 82 meshes with the gear 83, so that the first rotating shaft 64 drives the brush 65 to rotate to contact with the handle. Drive the rack 82 to move to the inside and reset. At this time, the first rotating shaft 64 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com