Multi-stage combined type efficient crushing cutter set for flour mill

A high-efficiency pulverizing and combined technology, applied in grain processing and other directions, can solve the problems of high power, unfavorable equipment energy saving, etc., and achieve the effects of long service life, high rotational speed and low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

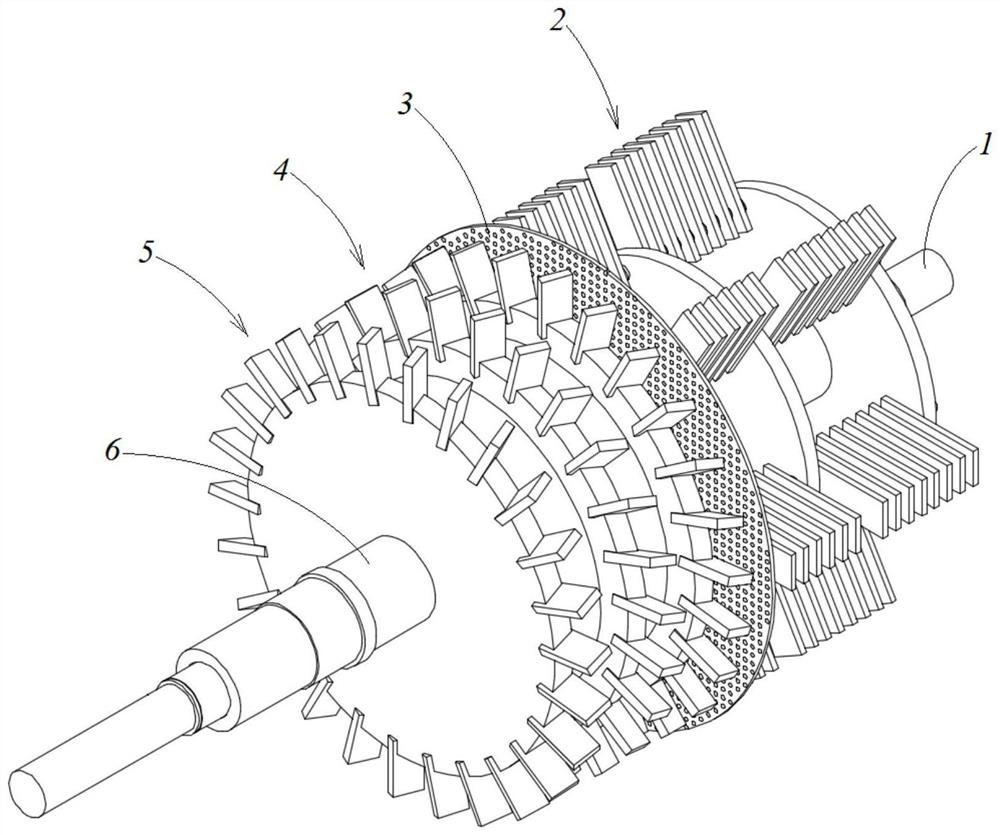

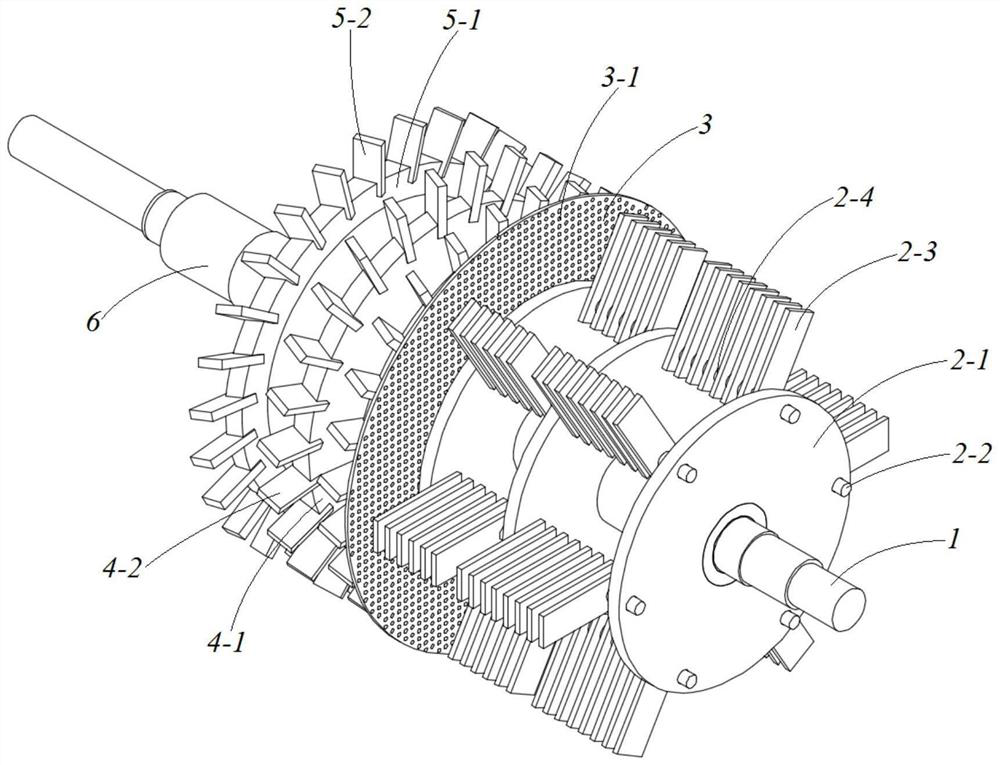

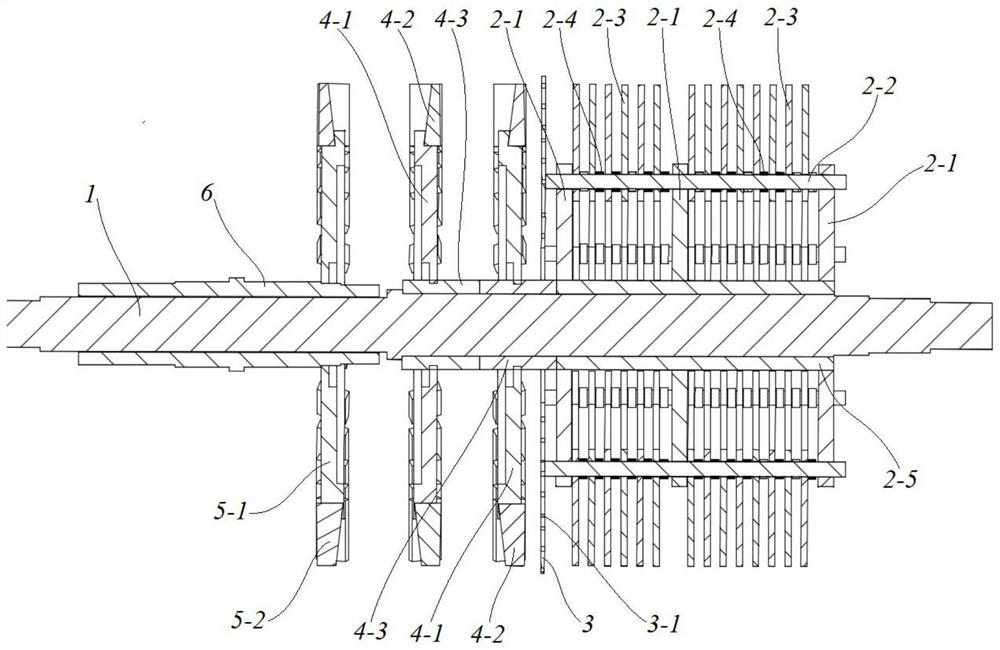

[0041] combine figure 1 , figure 2 and image 3 As shown, a multi-stage combined high-efficiency crushing knife set for a pulverizer in this embodiment includes a primary crushing knife set 2, a secondary crushing knife set 4, and a tertiary crushing knife set 5 arranged coaxially in sequence. The primary crushing knife group 2, the secondary crushing knife group 4 and the tertiary crushing knife group 5 are successively crushed step by step. The primary crushing knife group 2 and the secondary crushing knife group 4 are relatively fixed, and the two can rotate synchronously. And between the primary crushing knife set 2 and the secondary crushing knife set 4, a sieve plate 3 with several sieve holes 3-1 is provided, and the sieve plate 3 separates the primary crushing knife set 2 and the secondary crushing knife set 4 Separated, the primary crushing knife group 2 is used to coarsely crush the material, and the small particles after coarse crushing pass through the sieve hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com