Preparation method and application of Z-type alpha-Fe2O3/ZnIn2S4 composite photocatalyst

A -fe2o3, composite light technology, applied in the field of photocatalytic materials, can solve problems such as the improvement of unfavorable catalytic activity, poor specific surface effect, etc., to achieve the effect of photocatalytic activity, strong reducibility, and high photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

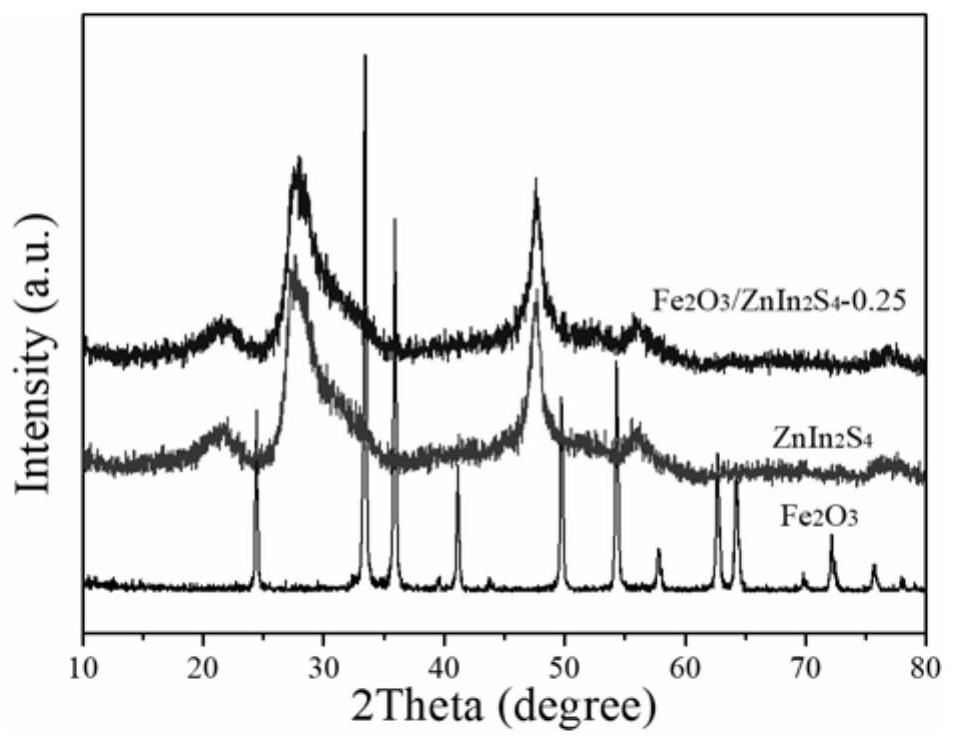

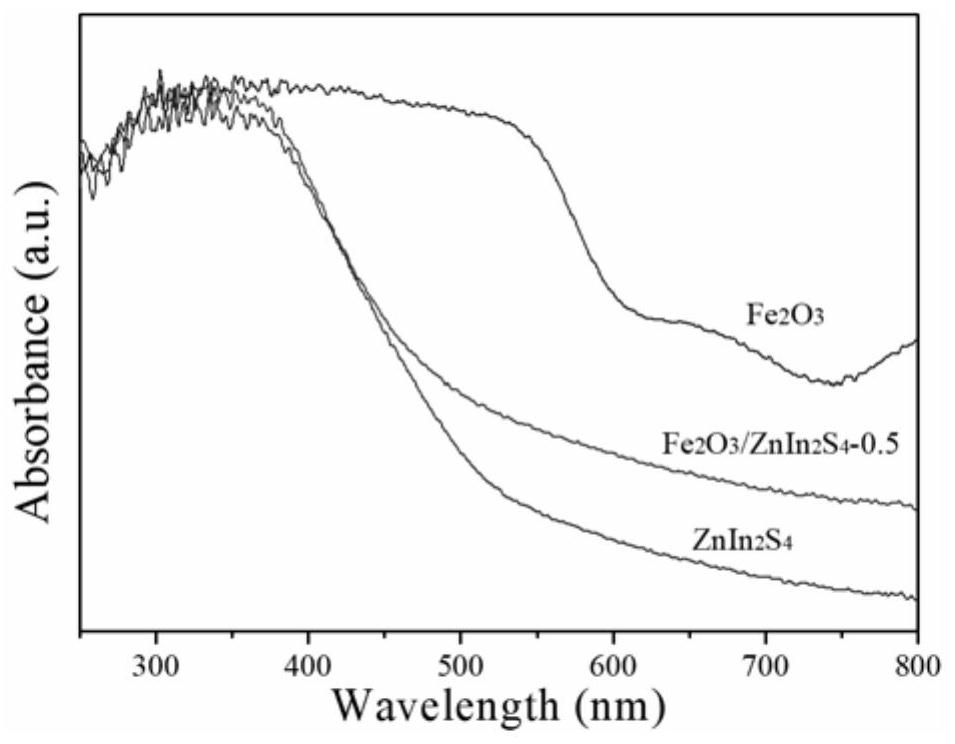

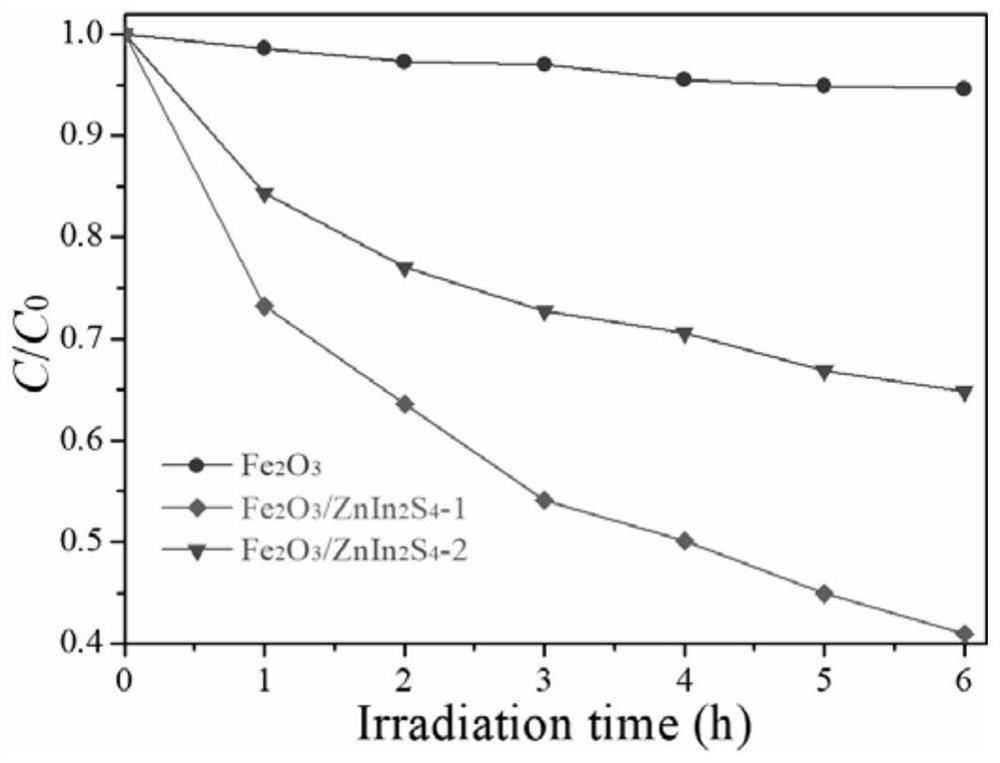

Embodiment 1

[0022] In a clean container, dissolve 0.25mmol of ferric nitrate, 1mmol of zinc nitrate, 2mmol of indium nitrate and 8mmol of thioacetamide in 75mL of dimethylformamide to form a mixed solution, and then, the mixed solution Transfer to a 100mL hydrothermal reaction kettle, control the hydrothermal reaction kettle in a sealed state, raise the temperature and control the temperature to react for 10 hours under the condition of 180°C, during the reaction process, since the hydrothermal reaction kettle is in a sealed state, as the temperature rises, During the reaction, the pressure of the system is positive, and the pressure of the system is also controlled at ≤0.3MPa during the reaction. After the reaction is completed, after natural cooling, high-speed centrifugation and water washing, the solid target product obtained is dried at 60°C , that is, α-Fe 2 o 3 / ZnIn 2 S 4 composite photocatalyst. According to the difference in the amount of ferric nitrate added, the prepared p...

Embodiment 2

[0025] In a clean container, dissolve 0.5mmol of ferric nitrate, 1mmol of zinc nitrate, 2mmol of indium nitrate and 8mmol of thioacetamide in 75mL of dimethylformamide to form a mixed solution, and then dissolve the mixed solution Transfer to a 100mL hydrothermal reaction kettle, control the hydrothermal reaction kettle in a sealed state, raise the temperature and control the temperature to react for 12 hours under the condition of 170°C, during the reaction process, since the hydrothermal reaction kettle is in a sealed state, as the temperature rises, When the reaction is carried out, the pressure of the system is positive, and the pressure of the system is also controlled at ≤0.3MPa during the reaction process. After natural cooling, high-speed centrifugation and water washing, the solid target product obtained is dried at 60°C to obtain α-Fe 2 o 3 / ZnIn 2 S 4 composite photocatalyst. According to the difference in the amount of ferric nitrate added, the prepared product...

Embodiment 3

[0028] In a clean container, dissolve 1mmol or 2mmol of ferric nitrate, 1mmol of zinc nitrate, 2mmol of indium nitrate and 8mmol of thioacetamide in 80mL of dimethylformamide to form a mixed solution, and then mix the Transfer the liquid to a 100mL hydrothermal reaction kettle, control the hydrothermal reaction kettle in a sealed state, raise the temperature and control the temperature to react for 14 hours under the condition of 180 ° C, during the reaction process, because the hydrothermal reaction kettle is in a sealed state, as the temperature increases During the rise and reaction, the pressure of the system is positive, and the pressure of the system is also controlled at ≤0.3MPa during the reaction process. After natural cooling, high-speed centrifugation, washing with water, and drying at 60°C, the α-Fe 2 o 3 / ZnIn 2 S 4 composite photocatalyst. According to the addition amount of ferric nitrate (1mmol or 2mmol), the products prepared by the method of this example a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com