Solenoid valve

A solenoid valve, electromagnetic technology, applied in the direction of electromagnets, magnets, electromagnets with armatures, etc., can solve the problems of small space for setting the return spring and few effective turns, and achieve the effect of suppressing deviation and improving action stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

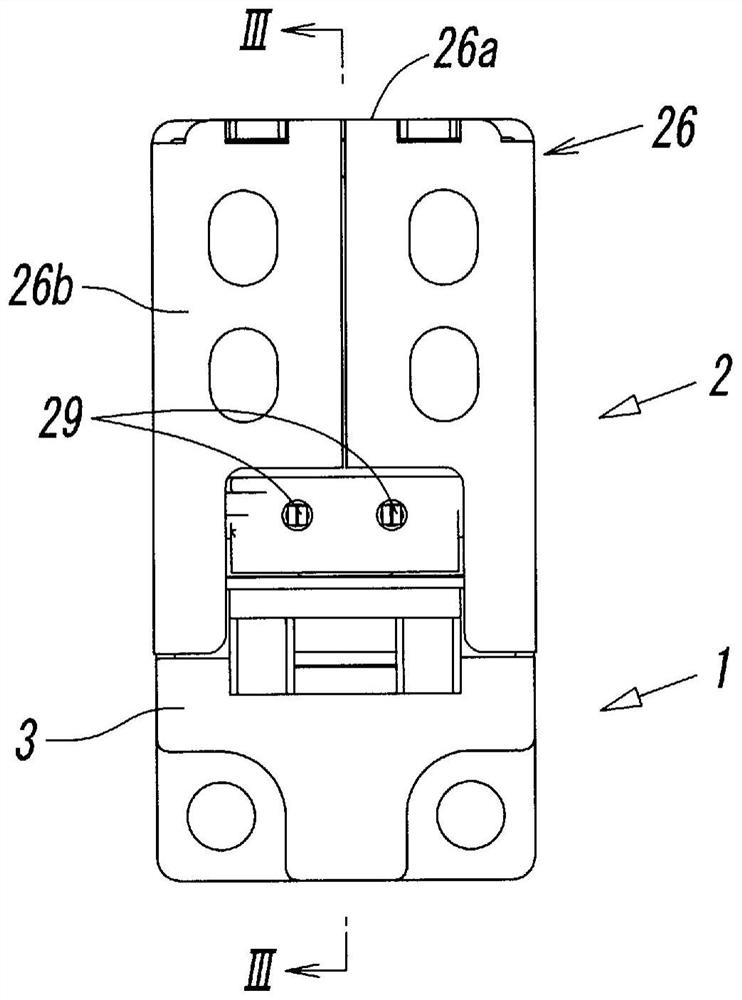

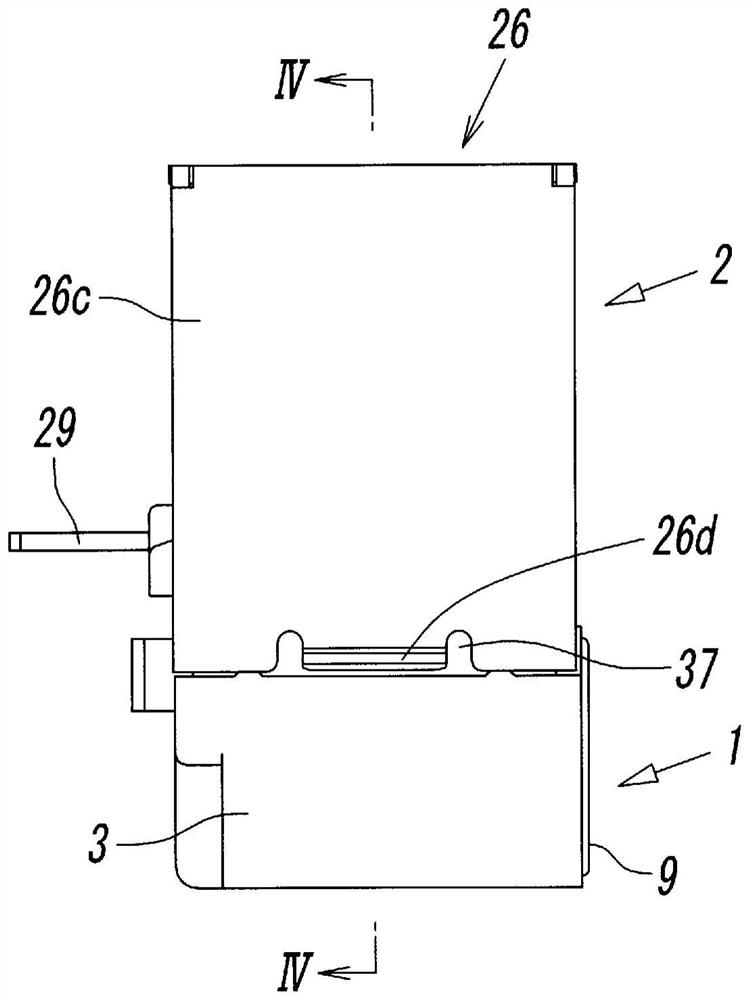

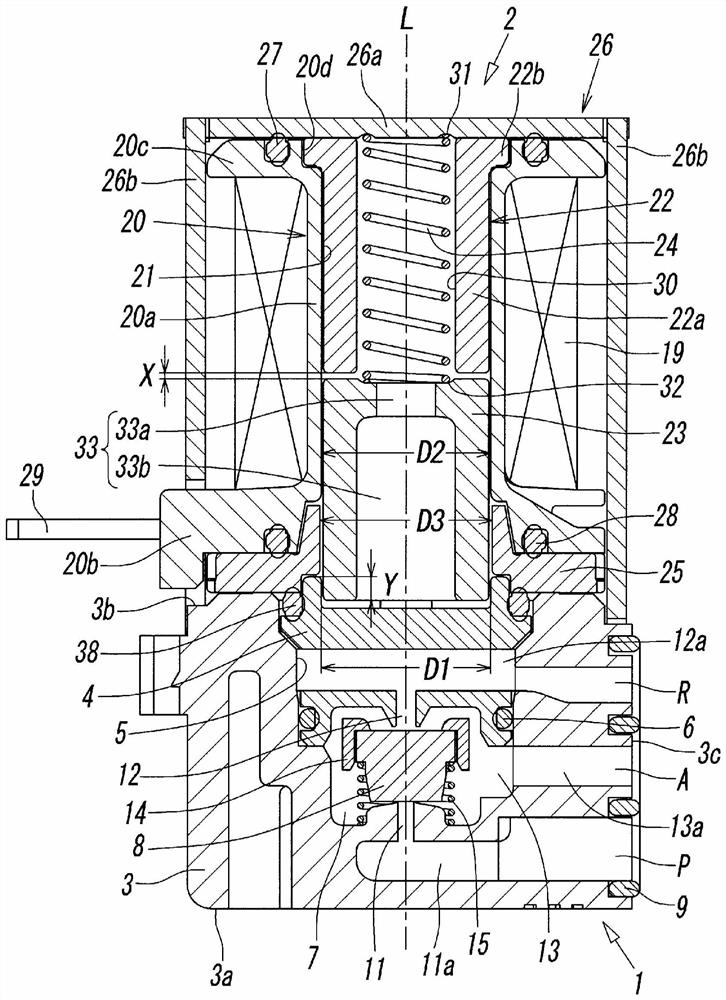

[0028] Figure 1-Figure 4 The solenoid valve shown is a three-port valve and has: a main valve part 1 having a valve member 8 for switching a fluid flow path; The electromagnetic operation parts 2 are connected in series along the axis L. As shown in FIG. The aforementioned axis L is an axis passing through the center of the bobbin hole 21 formed in the center of the bobbin 20 .

[0029] In addition, in the following description, the "proximal end" of each member forming the above-mentioned solenoid valve means figure 1 and figure 2 The end of the upper side, the "end" of each of the above components refers to figure 1 and figure 2 the end of the lower side.

[0030] The main valve unit 1 has a valve body 3 made of a non-magnetic material and a throttle 4 made of a non-magnetic material attached to the valve body 3 .

[0031] The valve body 3 has a rectangular block shape and has a first end (tip) 3a in the direction of the axis L and a second end (base end) 3b on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com