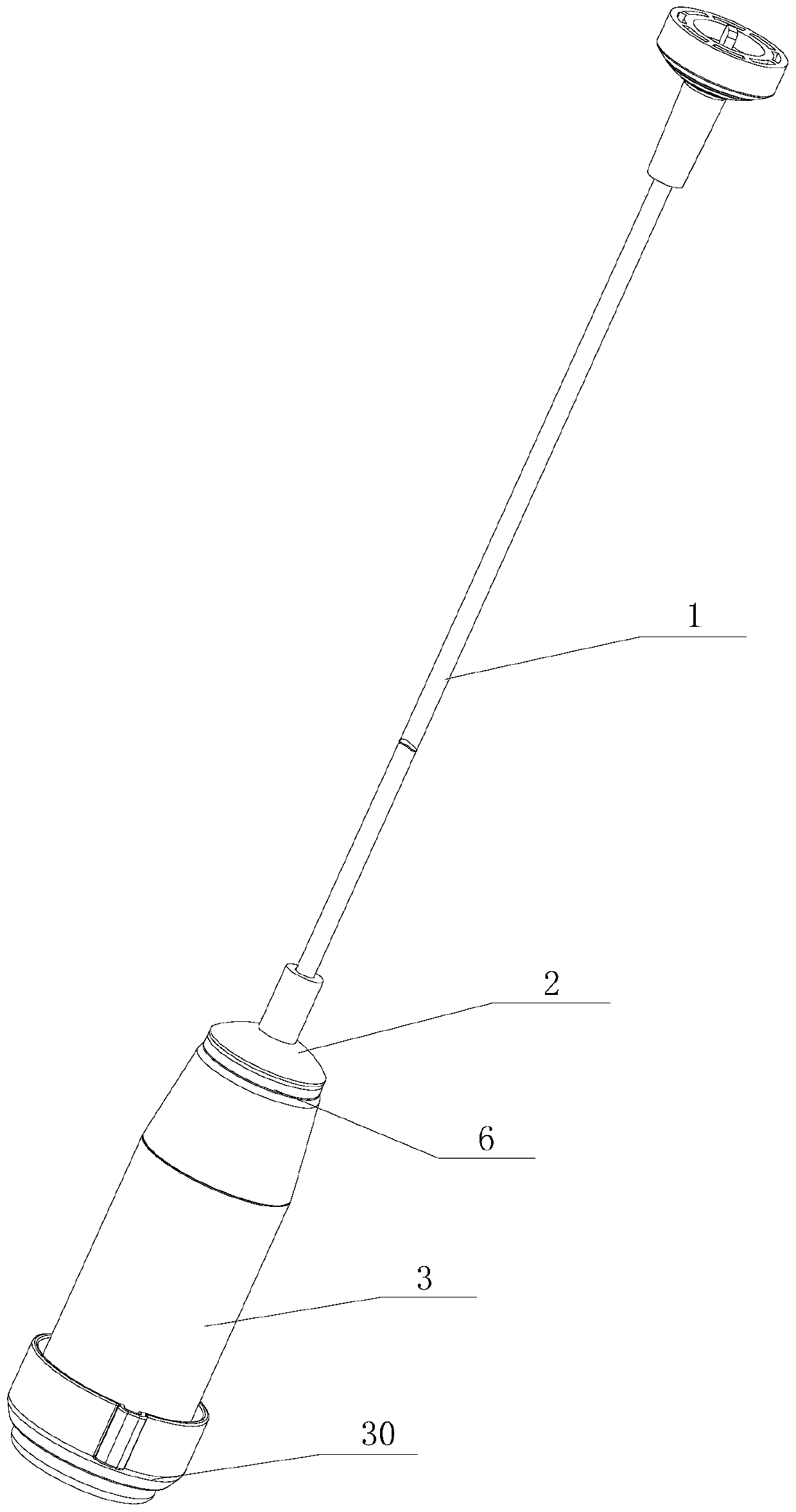

Variable damping vibration reduction device for washing machine and washing machine

A vibration damping device and variable damping technology, applied in the field of washing machines, can solve the problems of small spring deformation, reduced swing stability of the outer tub, large damping force, etc., so as to improve the level of vibration and noise, improve the dehydration start performance, and improve the vibration reduction. The effect of the noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

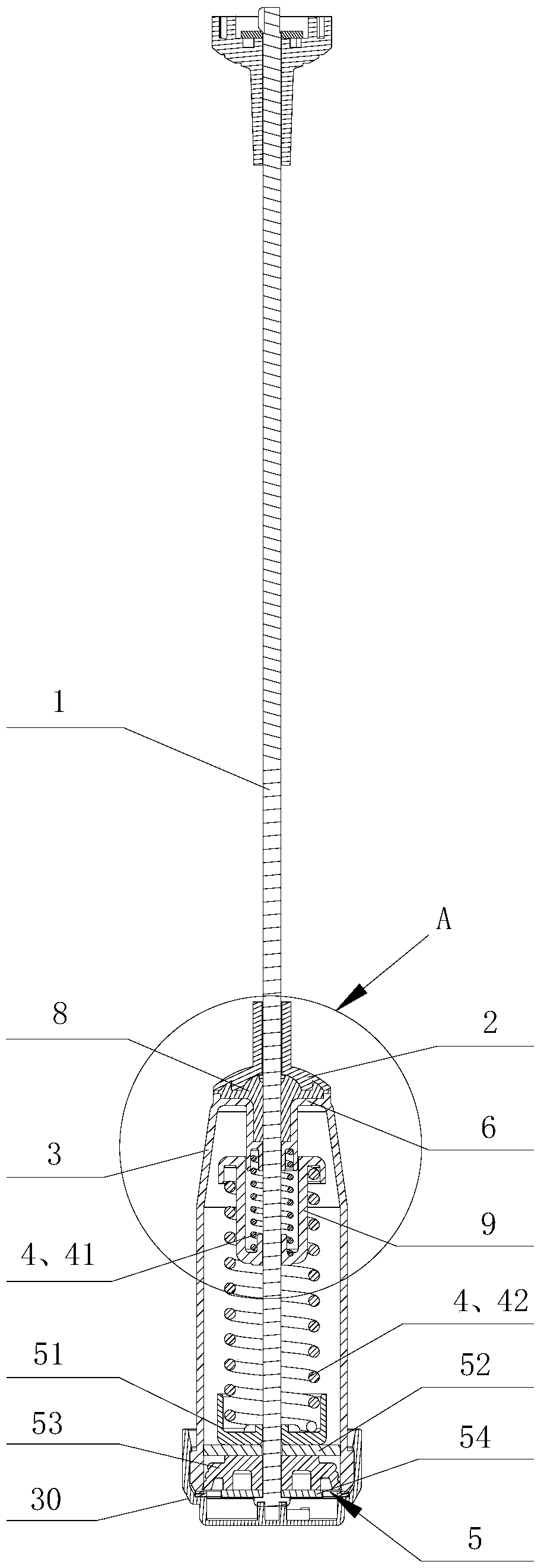

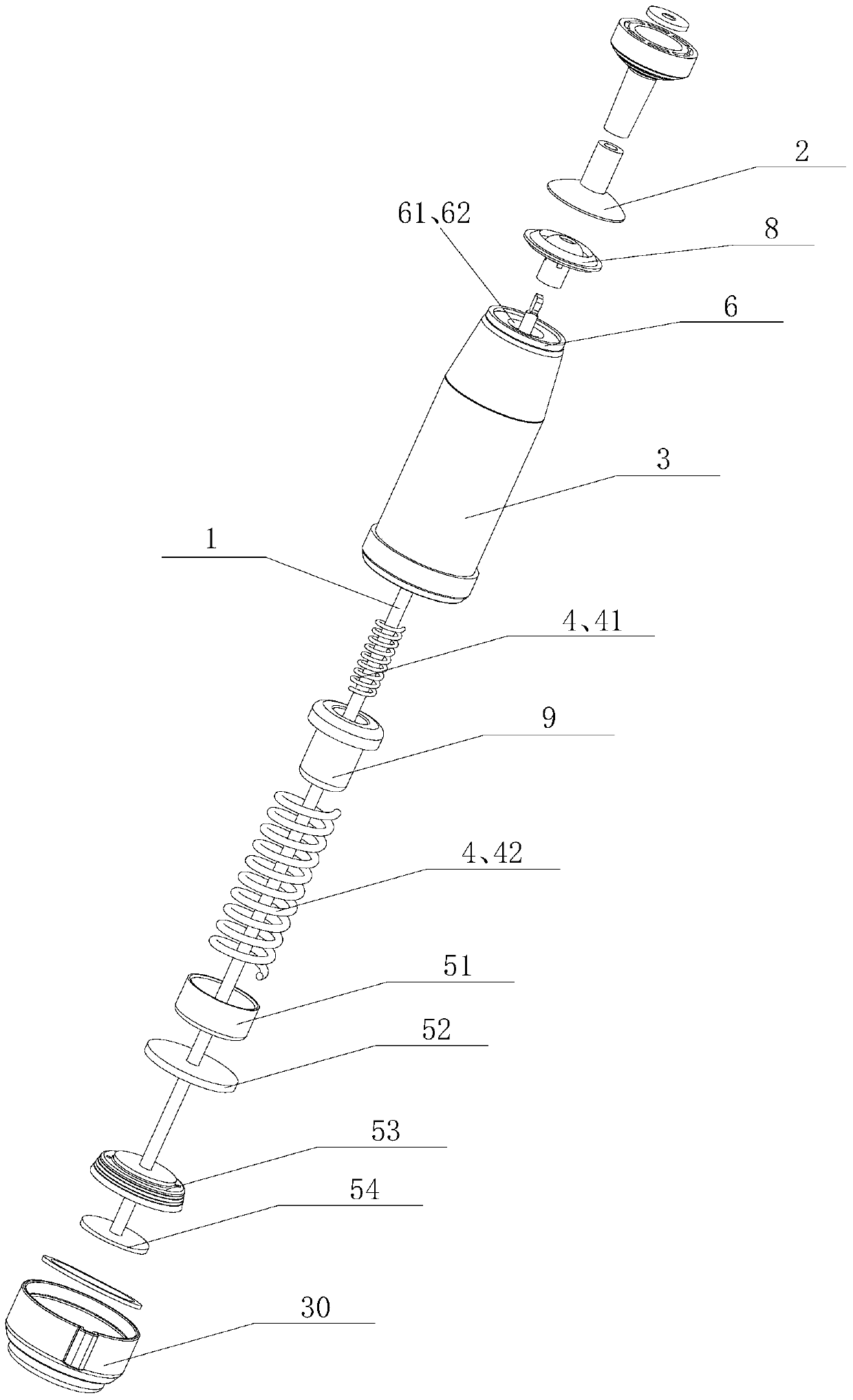

[0053] Such as figure 2 , image 3 , Figure 6 and Figure 10 As shown, the damping sleeve 8 described in this embodiment is arranged between the upper bracket 2 and the bracket 6, and the damping sleeve 8 includes a tray 81 supporting the upper bracket 2, which is located under the tray 81 and extends into the To the support sleeve 82 in the bracket 6 and the hanger installation hole 83 axially penetrating the tray 81 and the support sleeve 82 . The damping sleeve 8 is a damping rubber sleeve with a T-shaped integral structure as a whole.

[0054] Further, such as Figure 4 As shown, the pallet 81 is provided with a first variable damping structure 10 that makes the inner diameter of the boom installation hole 83 smaller after being stressed, and the first variable damping structure 10 is arranged on the upper end surface of the pallet 81 to support the upper bracket 2, and The downward pressure of the support 2 is converted into the radial deformation pressure of the d...

Embodiment 2

[0060] Such as Figure 8 and Figure 11 As shown, the damping sleeve 8 described in this embodiment is arranged between the bracket 6 and the pressure buffer mechanism, and the pressure buffer mechanism includes an upper spring seat 7, a damping spring 4 and a lower spring seat 5, and The vibrating spring 4 is installed between the upper spring seat 7 and the lower spring seat 5, and the damping sleeve 8 includes a tray 81 supporting the bracket 6, a support sleeve 82 arranged below the tray 81 and extending into the upper spring seat 7 and Axially penetrates the suspension rod installation hole 83 of the tray 81 and the support sleeve 82 . The damping sleeve 8 is a damping rubber sleeve with a T-shaped integral structure as a whole.

[0061] Further, the pallet 81 is provided with a first variable damping structure 10 that makes the inner diameter of the boom mounting hole 83 smaller after being stressed (see Figure 4 ), the first variable damping structure 10 is set on t...

Embodiment 3

[0067] This embodiment is the combination of embodiment one and embodiment two, such as Figure 9 As shown, a damping sleeve 8 is provided between the upper bracket 2 and the bracket 6, and between the bracket 6 and the pressure buffer mechanism.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com