Fluid damper

A fluid damper, fluid technology, applied in liquid shock absorbers, shock absorbers, shock absorbers, etc., can solve problems such as long-term continuous standby, and achieve the effect of good vibration suppression and small damping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0083] Hereinafter, the configuration of the present invention will be described in detail with reference to the preferred embodiments shown in the drawings.

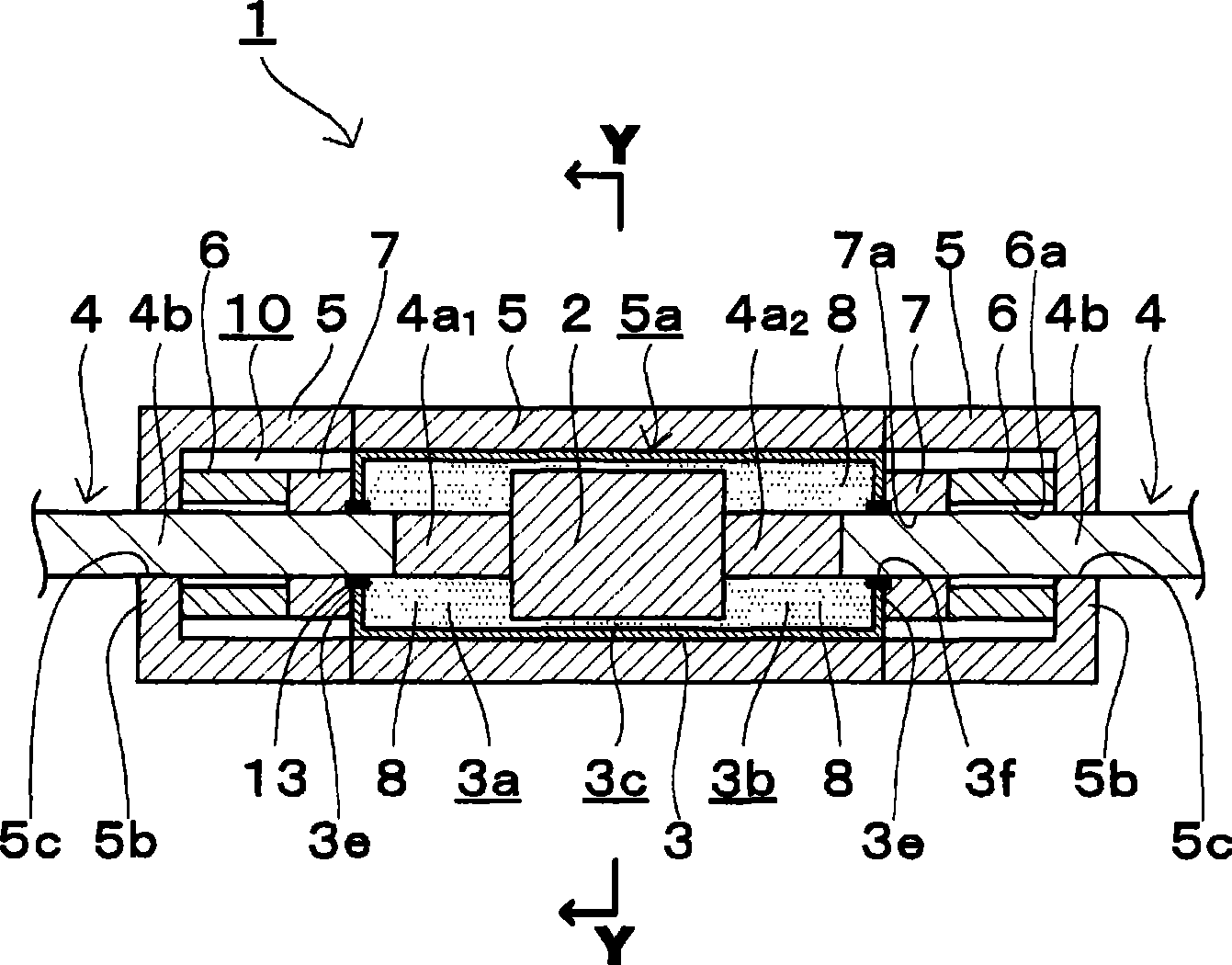

[0084] figure 1 ˜ FIG. 5 show a first embodiment of the fluid damper of the present invention. The fluid damper 1 has: a magnetic fluid 8; a magnetic piston 2; a cylinder 3 that seals the magnetic fluid 8 and accommodates the piston 2; a piston rod 4 that penetrates the cylinder 3 and supports the piston 2; A magnetic field generating device 6 outside the cylinder 3; a first yoke piece 5 disposed around the cylinder 3; and a second yoke piece 7 disposed around the piston rod 4 outside the cylinder 3.

[0085] The cylinder 3 has a cylindrical peripheral wall and end face members 3 e at both ends in the axial direction, and a hollow portion, that is, a cylinder chamber is formed by them. 3 f of through-holes through which the piston rod 4 penetrates are provided in the center part of the end surface member 3e. In additi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com