Brake-shoe-type centrifugal clutch

A centrifugal clutch and brake block technology, applied in the field of clutches, can solve the problems of fast decay of the spring force, reduction of the coupling speed of the centrifugal clutch, engine damage, etc., and achieve the effect of relatively small deformation of the work, insignificant attenuation of the spring force, and stable combination speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

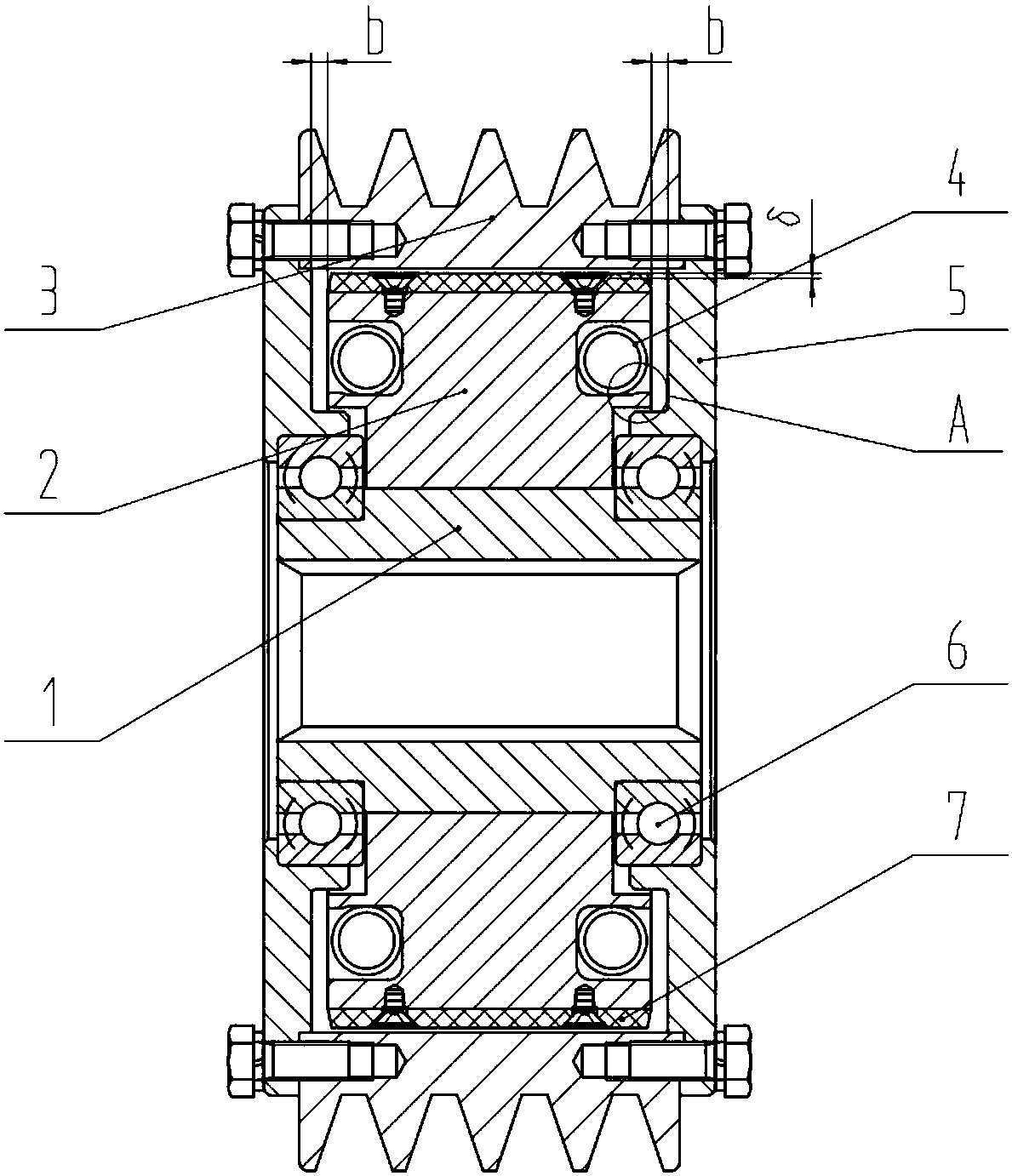

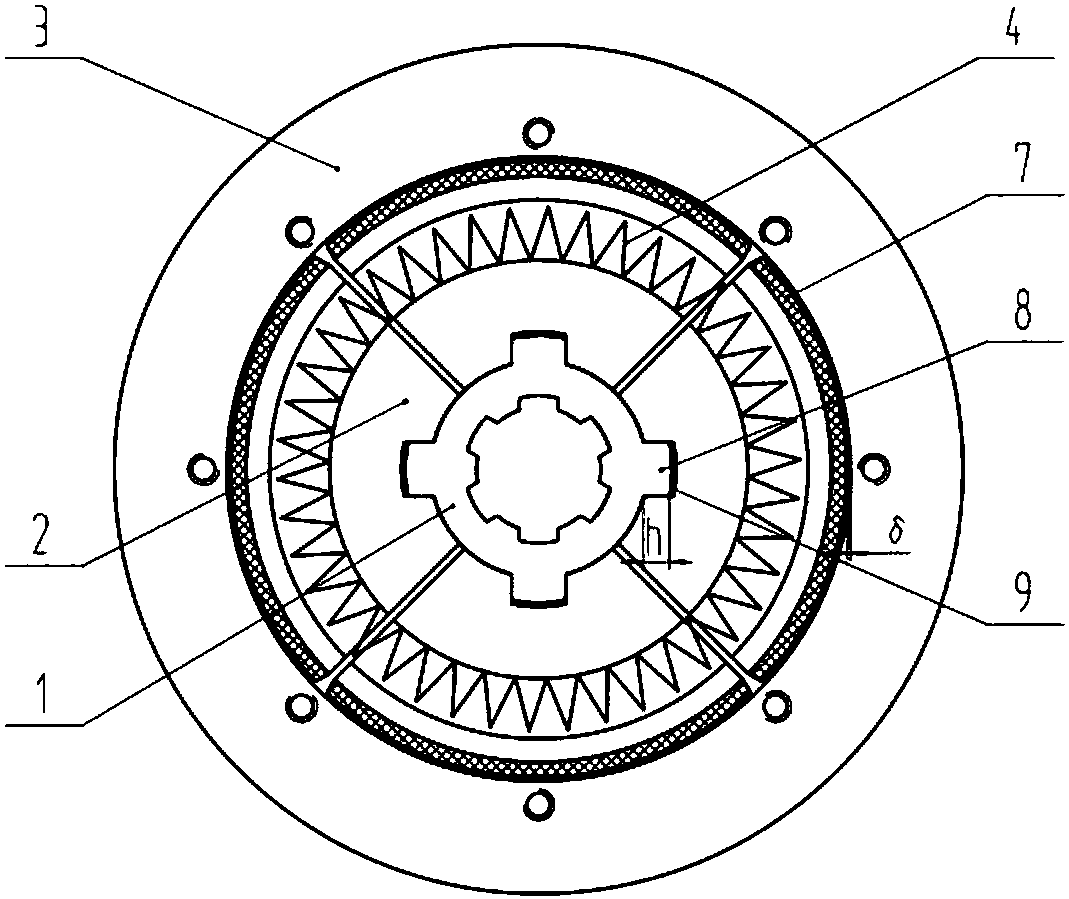

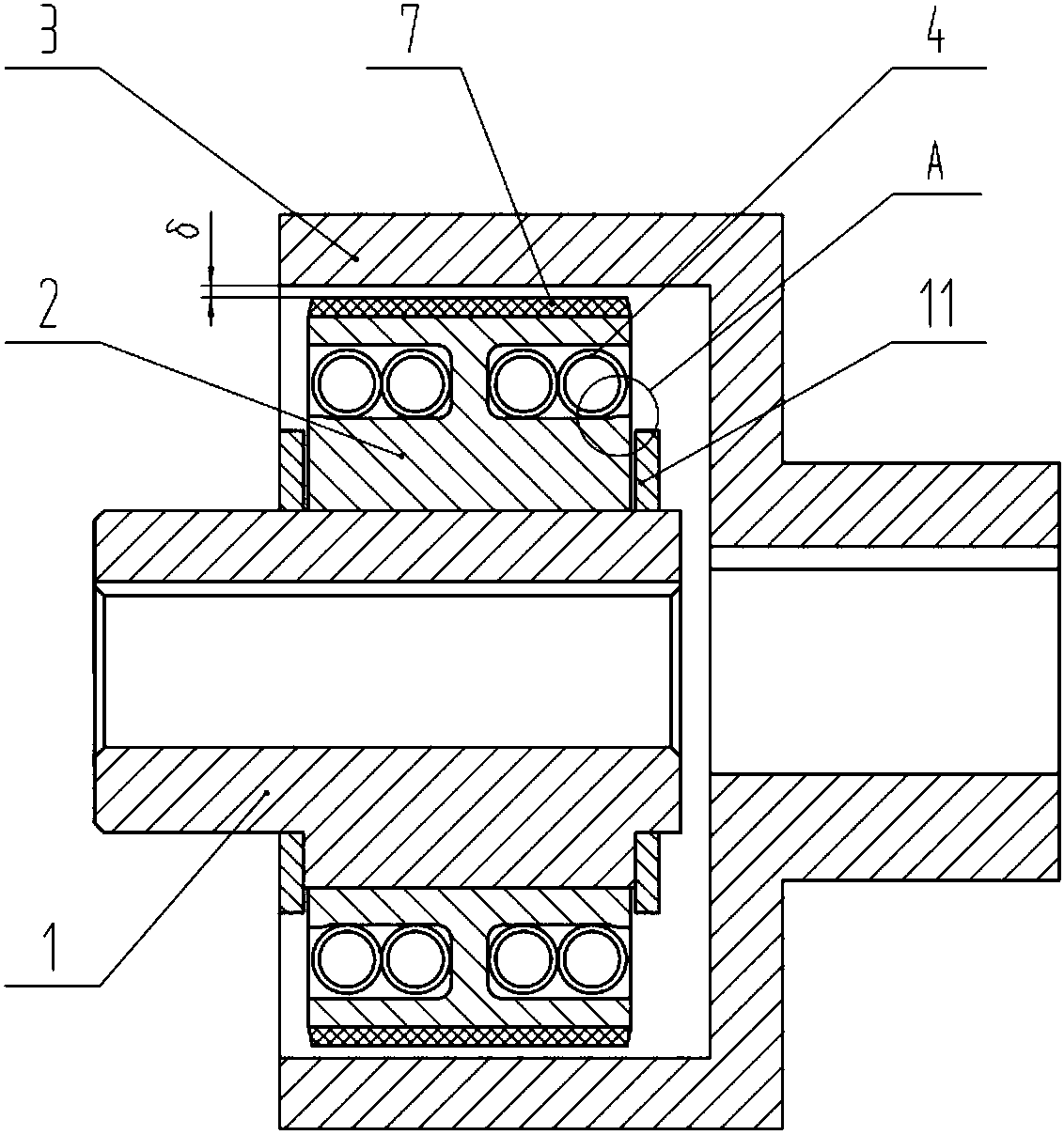

[0030] Such as figure 1 As shown: the active part 1 is a hollow shaft, the inner hole is provided with keyways or internal splines, several bosses / grooves are uniformly arranged on the outer circle, and several fan-shaped centrifuges are arranged on the outer side of the outer circle corresponding to each boss / groove 2. There is only a slight gap between the centrifugal bodies 2, and all the centrifugal bodies 2 form a complete circle surrounding the active part 1. There is a groove / boss on the inner diameter of the centrifuge 2, the groove / boss is just nested on the boss / groove of the active part 1, and can slide up and down, and the active part 1 and the centrifuge are nested through this concave and convex 2 can be rotated together. For balance, the grooves / bosses should be arranged symmetrically along the center of the centrifugal body 2 . The end face...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com