Early warning system and method for grounding deterioration of rotor slip ring

A conversion system and rotor technology, which is applied in the field of iron and steel production, can solve problems such as the hidden dangers of safe and stable operation of the finishing rolling motor, the instability of the rolling system of the finishing rolling product, and the grounding degradation of the rotor slip ring, so as to achieve clarity and logic , improve the tolerance of the operating environment, and improve the effect of accuracy and timeliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

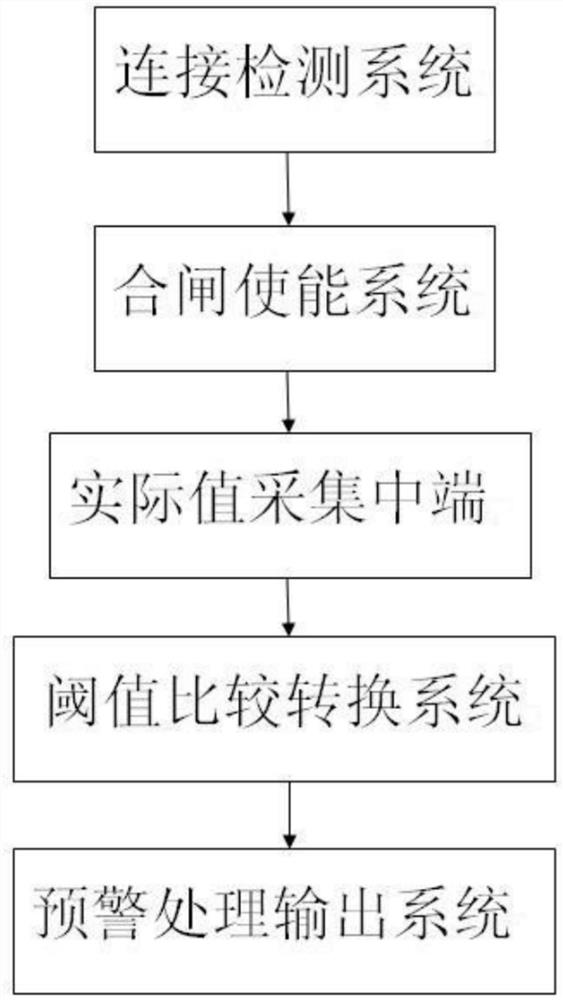

[0033] according to figure 1 As shown, this embodiment proposes a system for early warning of ground degradation of rotor slip rings, including a connection detection system, a closing enabling system, an actual value acquisition middle end, a threshold value comparison conversion system, and an early warning processing output system. The system is used to connect the left phase and the middle phase of the three-phase alternating 170V power supply, and provide 220V driving voltage to provide driving power for the detection system; the closing enabling system is used to trigger the closing signal of the system, and connect the three-phase AC and two-phase DC, and then trigger the system enable signal to drive the entire rotor slip ring system into a normal rotation cycle; the core of the connection detection system is to connect first and then detect. The logical sequence and logical relationship of the entire subsystem are very important, because in the design of the entire cir...

Embodiment 2

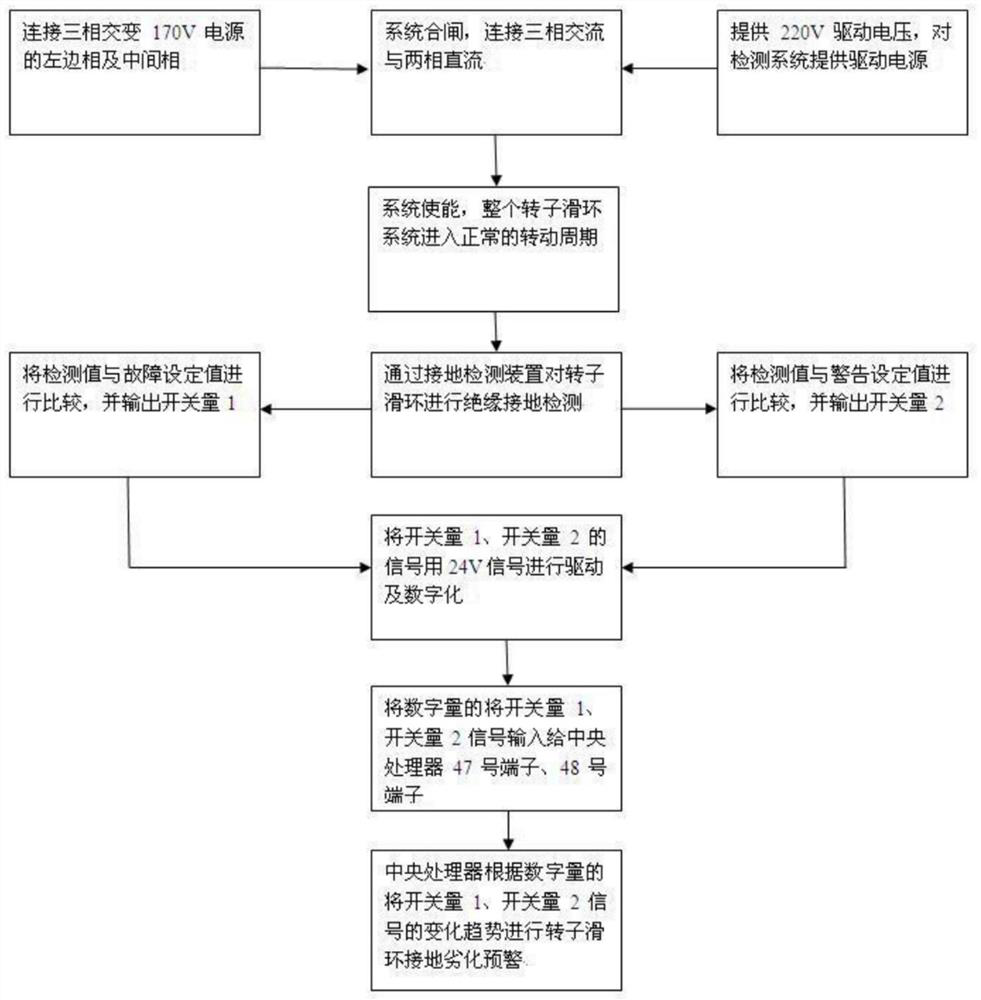

[0040] according to figure 2 As shown, this embodiment proposes a method for early warning of ground degradation of the rotor slip ring, including the following steps:

[0041] Step 1: Start the connection detection system and connect to the left phase and the middle phase of the three-phase alternating 170V power supply;

[0042] Step 2: use the connection detection system to provide 220V drive voltage, and provide drive power to the detection system;

[0043] Step 3: Start the closing enabling system, trigger the closing signal of the system, close the system, and connect the three-phase AC and two-phase DC. The closing of the system is the connecting link of the whole system. Two different states treat the circuit system differently, so as to perform switch control according to the working conditions; such a design of switching control according to the working conditions can ensure that the slip ring system will not have power during maintenance, and can ensure the safety...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com