Wafer test probe station with high performance and high efficiency

A Wafer Test, High Efficiency Technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the techniques, creative characteristics of the present invention, it is easy to understand that the present invention is further illustrated in connection with the specific embodiments.

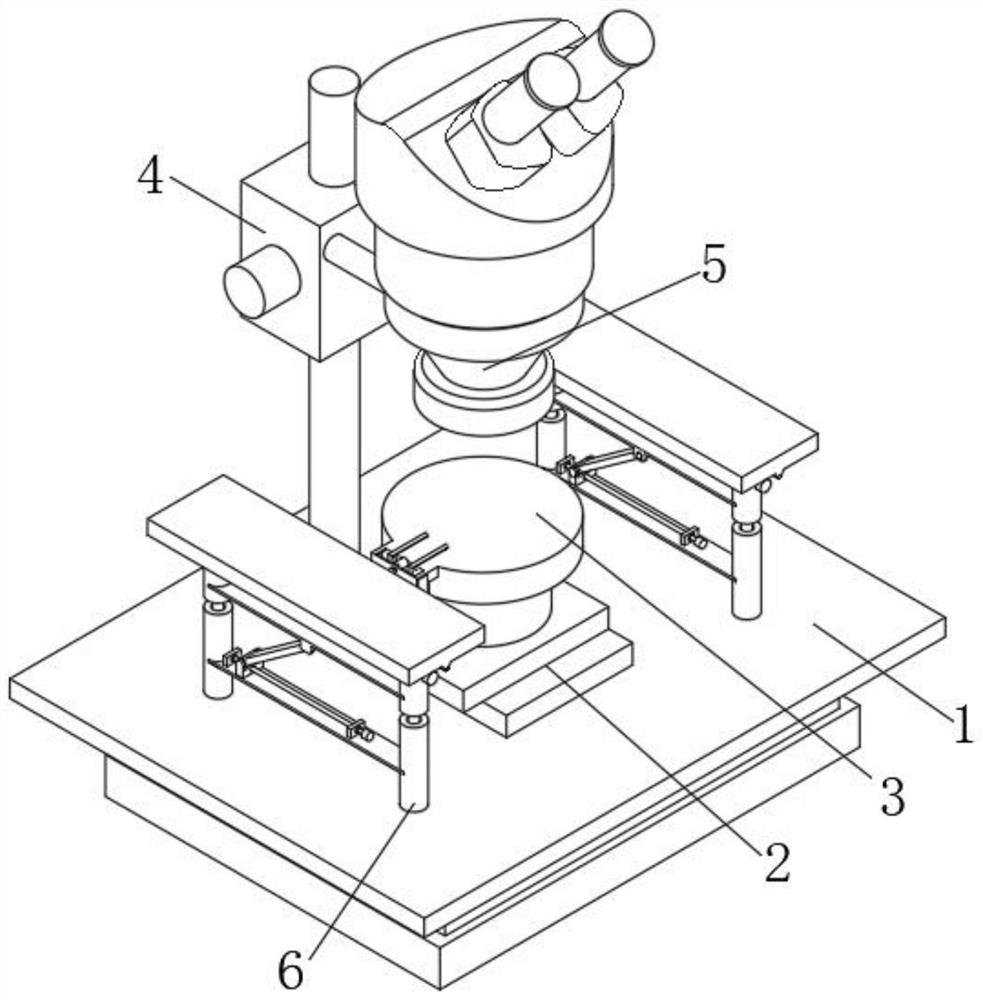

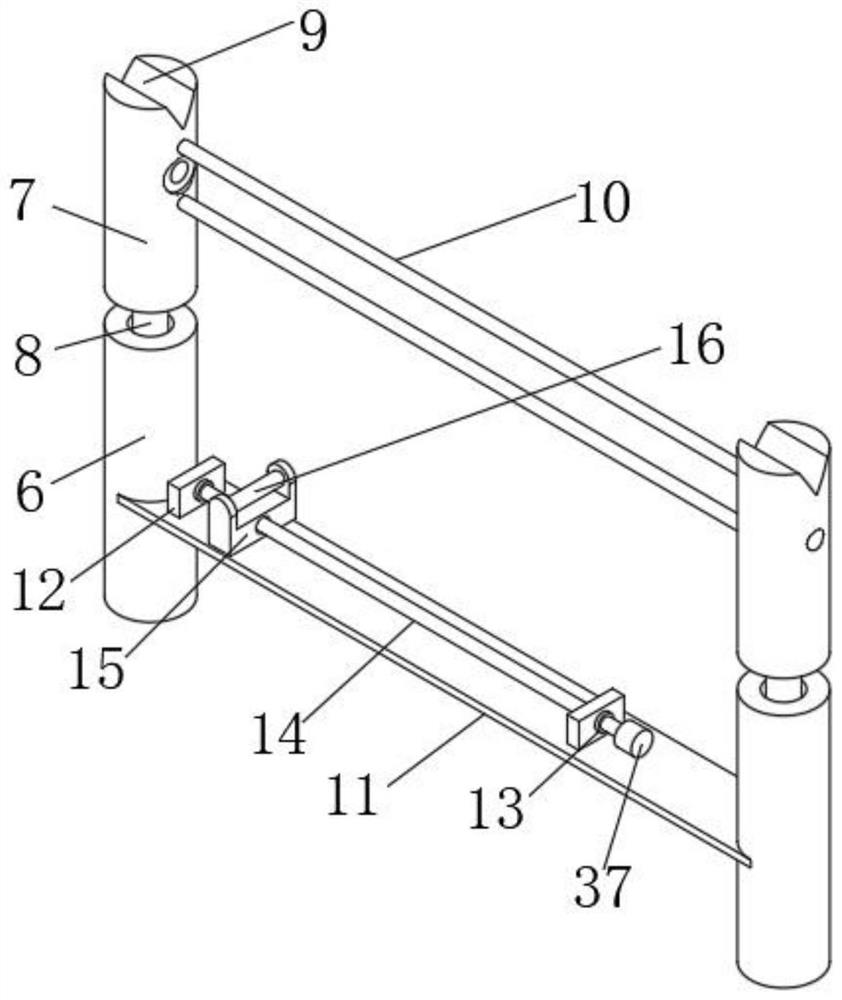

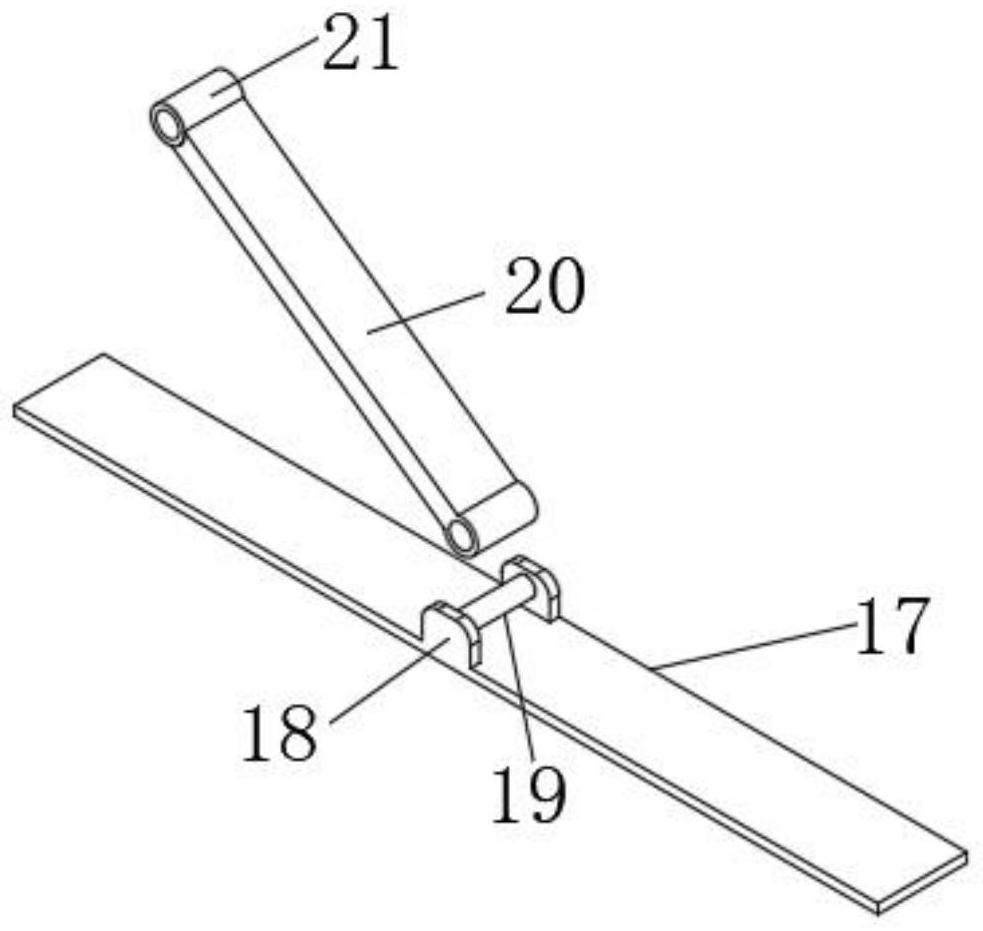

[0025] Such as Figure 1-6 As shown, a wafer test probe station having high performance high-performance, including the No. 1 mounting table 1, a lateral longitudinal adjustment stage 2, and the lateral longitudinal adjustment stage 2 is provided with a table 3 The rear side position of the table 3 is provided with a rear bracket 4, and the rear bracket 4 is provided with a viewing mirror barrel 5, and the first mounting table 1 is provided with a side lower mounting tube 6 on both sides of the table 3. The internal movable rod 8 is provided in the side lower mounting tube 6, and the upper end position of the inner movable rod 8 is provided with a side mounting column 7, and the lower mounting plate 11 is provided between the side surface mount 6, and the lower mounting pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com