An anti-rolling device and its bogie

A bogie and anti-roll technology, which is applied in the direction of the device for lateral relative movement between the underframe and the bogie, can solve the adverse effects of the safety, reliability, and stability of the bogie, and cannot guarantee the torsion of the anti-roll device. Consistent rod height, high height of anti-rolling device from rail surface, etc., to achieve the effect of improving the stress state of torsion bar, compact structure, and improving the stress state of torsion bar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] For the convenience of description, the description of the relative positional relationship of each component (such as: front, rear, etc.) is described according to the layout direction of the drawings in the specification, and does not limit the structure of this patent.

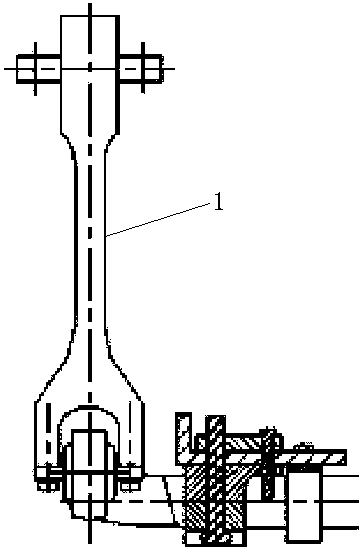

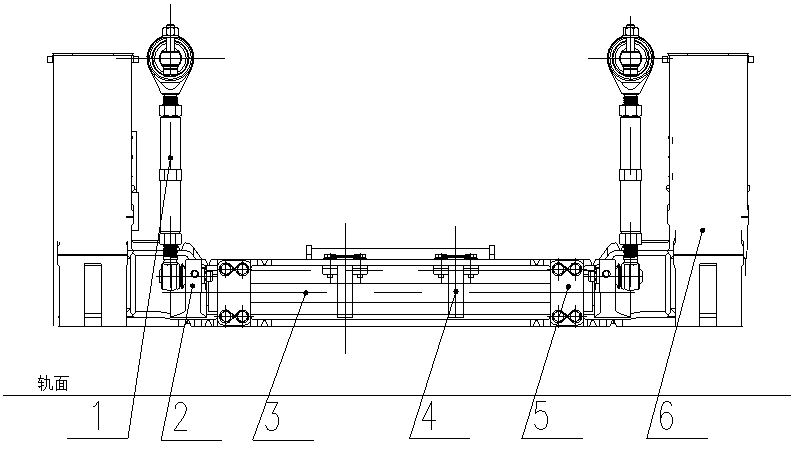

[0046] Such as Figure 2-6 As shown, an anti-rolling device includes a pair of tension and compression rods 1, a torsion arm 2 hinged to the lower end of each tension and compression rod 1, a torsion arm 2 arranged between the two torsion arms 2 and connected to the torsion arm 2. pole 3.

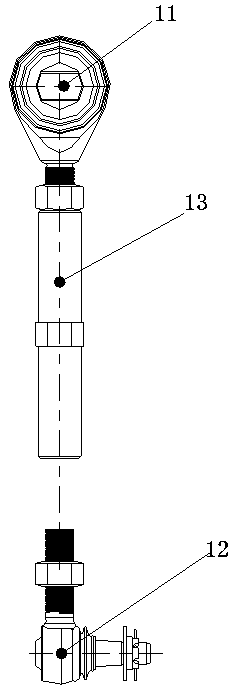

[0047] The tension and compression rod 1 is a telescopic tension and compression rod, and its structure includes an upper joint link 11 , a lower joint link 12 , and an intermediate link 13 connecting the upper joint link 11 and the lower joint link 12 .

[0048] The intermediate connecting rod 13 is threadedly connected with the upper joint connecting rod 11 and the lower joint connecting rod 12, and is fastened...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com