Device for dredging pipe blocked by initial setting cement paste and construction method

A technology for plugging pipes and mud, which is applied in the direction of measuring devices, material analysis using sound waves/ultrasonic waves/infrasonic waves, instruments, etc., can solve the problems that cement slurry cannot be replaced in time, and achieve the goal of reducing cleaning difficulty, simple overall mechanism, and ease of use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

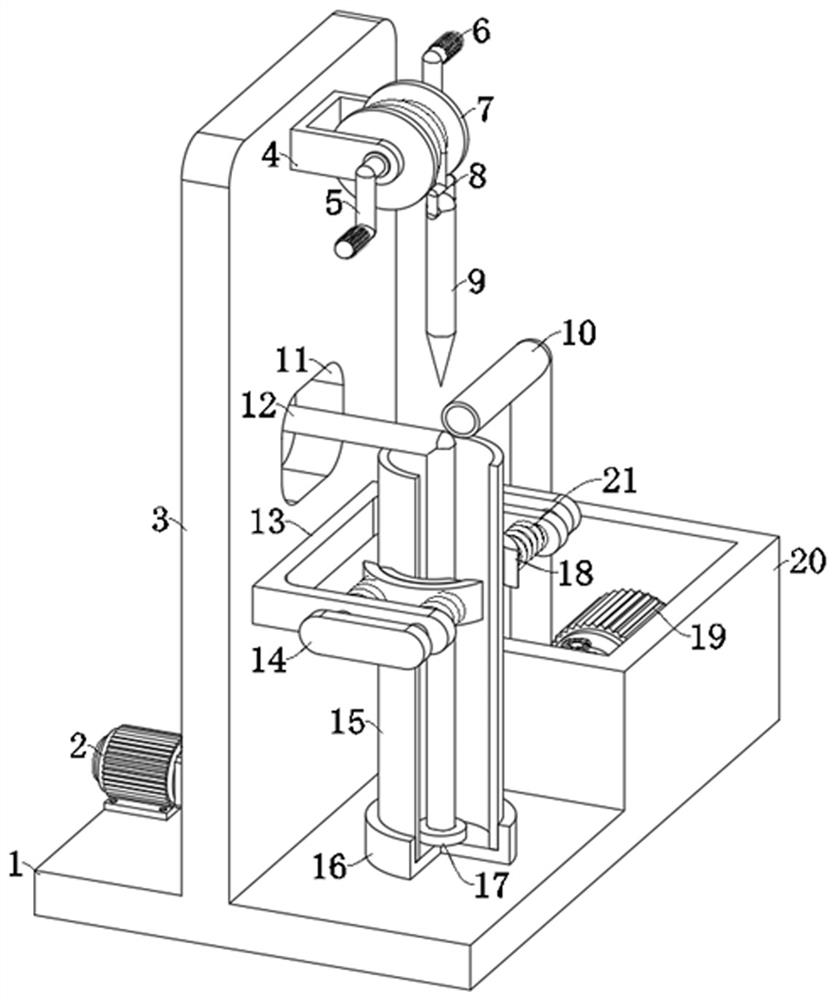

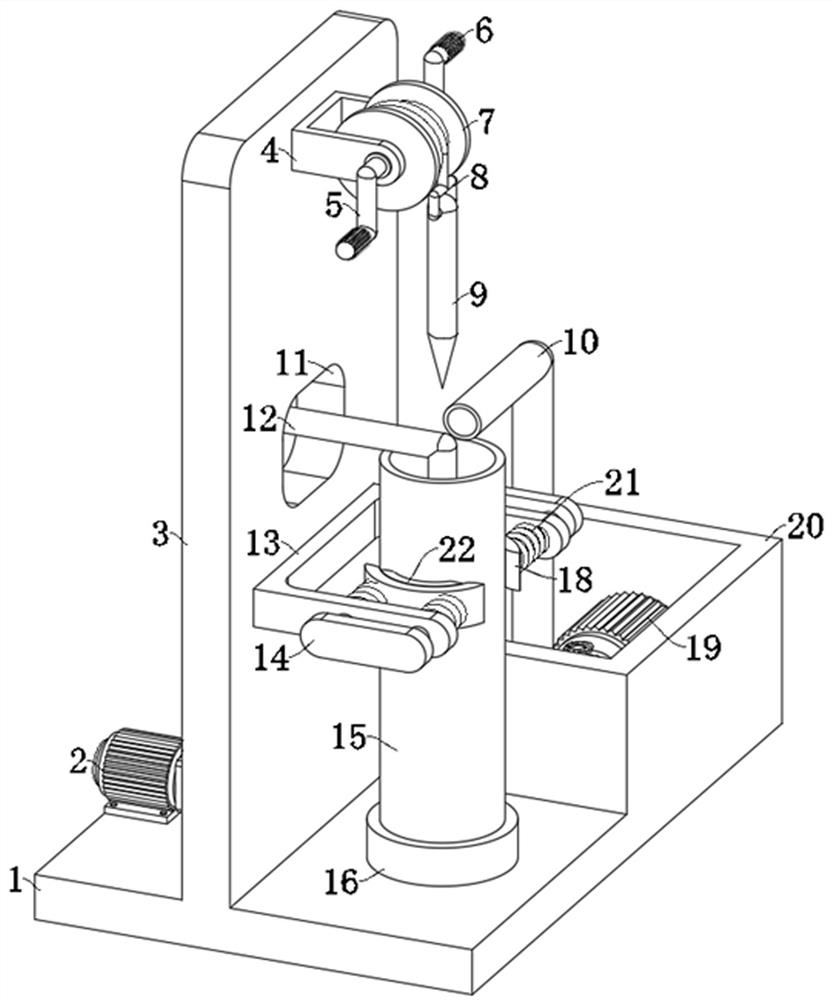

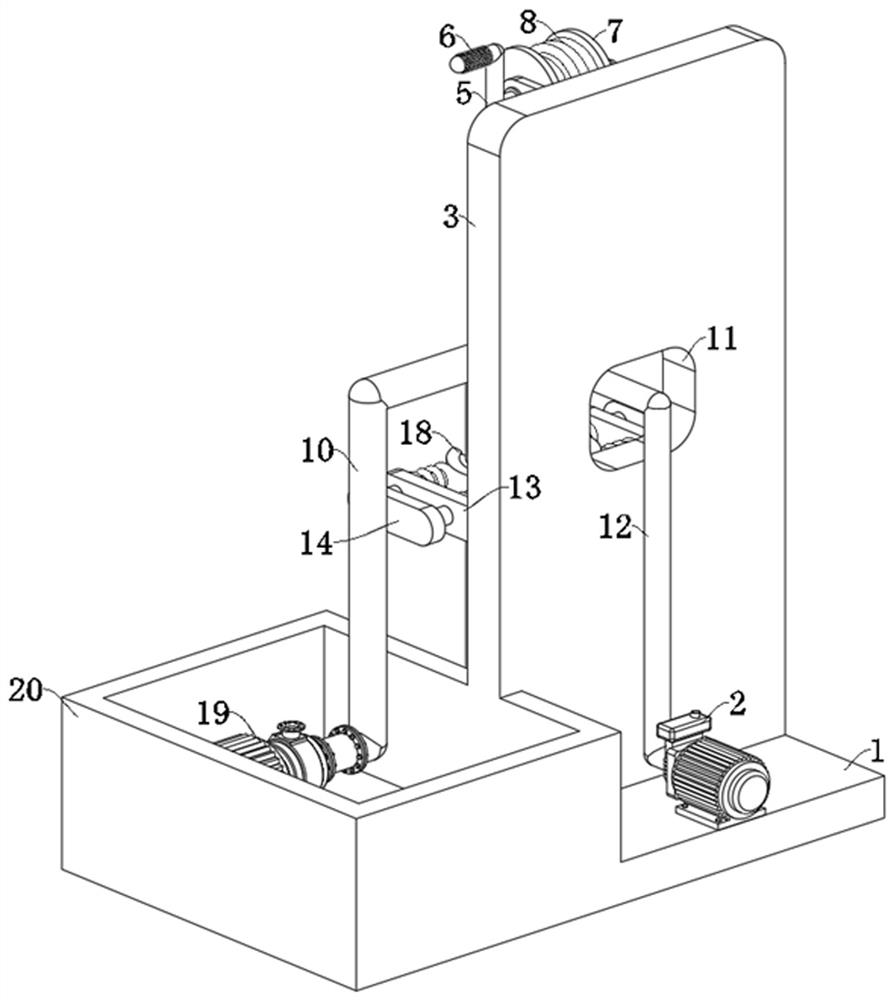

[0036] refer to Figure 1-6 : A kind of device that is used for dredging the blocked pipe of initial setting cement slurry, comprises: the base 1 that is provided with support plate 3 on the top; Clamping mechanism, is located on the support plate 3, is used for the clamping of cleaned pipe, wherein, clamps The holding mechanism includes installation buffer parts, two splints 18 and two anti-slip rubber pads 22, and the sides of the two splints 18 away from each other are respectively fixedly connected to the two ends of the installation buffer parts, and the two anti-skid rubber pads 22 are fixedly connected to the two sides respectively. One side of two splints 18 close to each other; and an impact mechanism, which is located on the support plate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com