Inspection platform and inspection method for stamping aluminum part

An inspection method and platform technology, used in measuring devices, material analysis by optical means, instruments, etc., can solve problems such as slow inspection speed, cracking and dark cracking of aluminum parts, and achieve improved inspection speed, good quality inspection, The effect of improving efficiency and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0032] The detailed features and advantages of the present invention are described in detail below in the specific embodiments, the content of which is sufficient to enable any person skilled in the art to understand the technical content of the present invention and implement it accordingly, and according to the specification, claims and drawings disclosed in this specification , those skilled in the art can easily understand the related objects and advantages of the present invention.

[0033] Inspection platform of the present invention is specifically as follows:

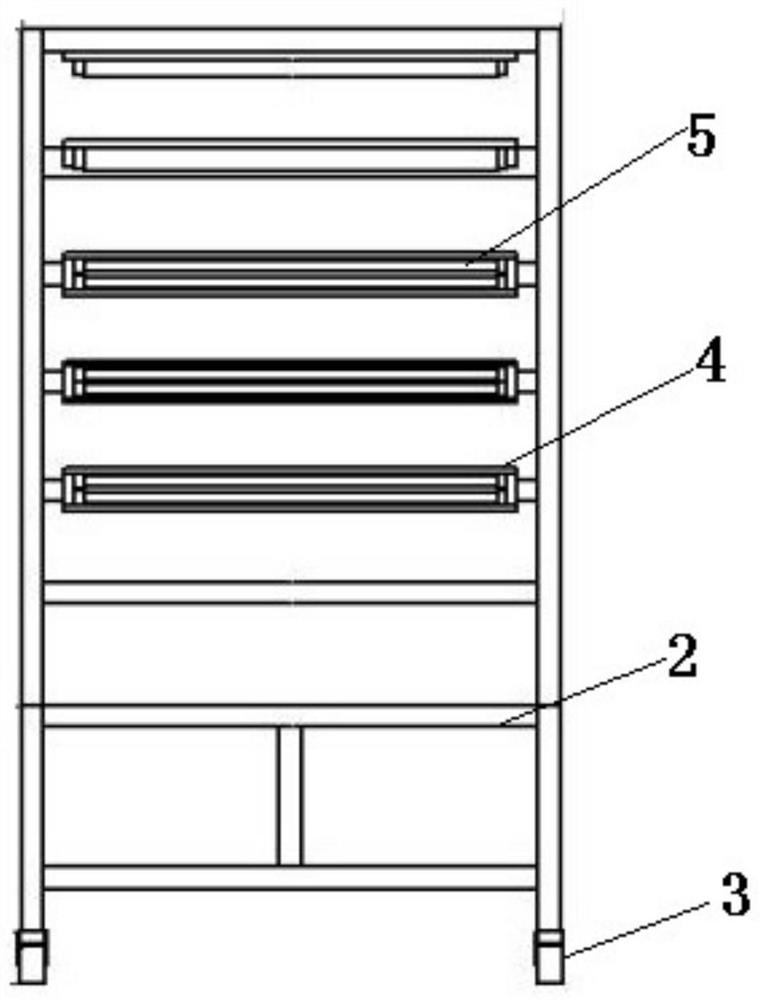

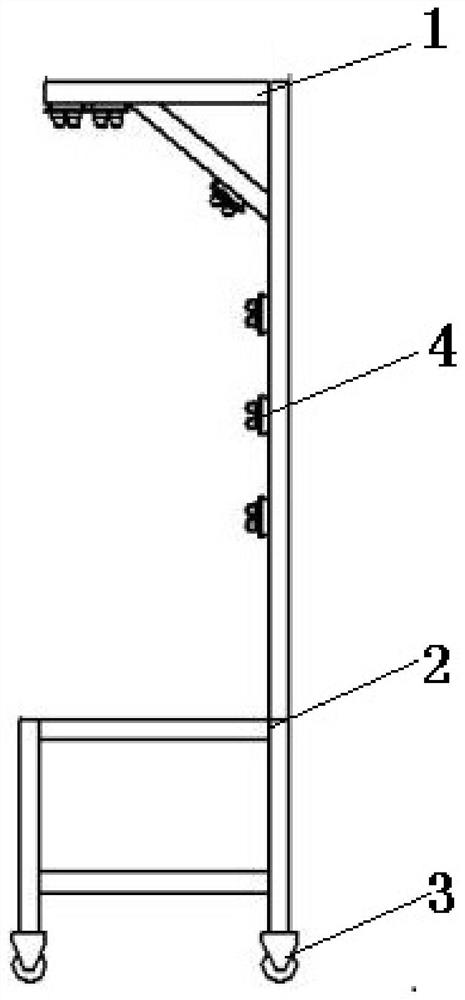

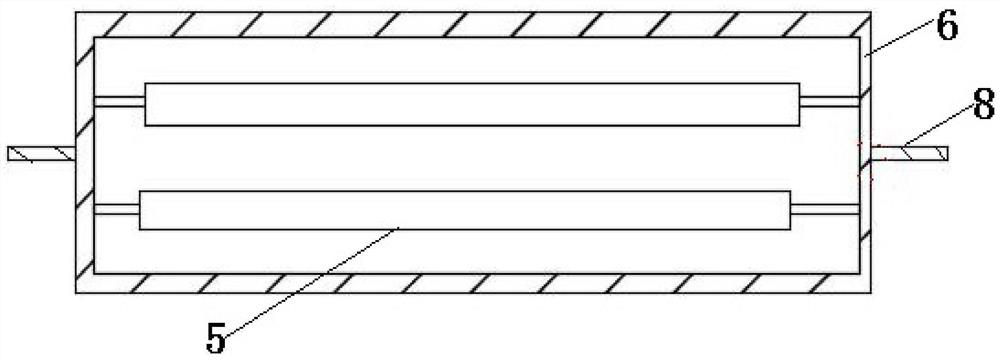

[0034] as attached figure 1 , attached figure 2 Shown is an inspection platform for stamped aluminum parts. The inspection platform includes an "A-frame" 1 in the upper part and an inspection table 2 in the lower part. The "A-frame" 1 and the inspection table 2 are integral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com