Explosion-proof pressure detection device for sealing ring

An explosion-proof pressure and detection device technology, which is applied in the direction of machine sealing ring testing, measuring devices, and the use of stable tension/pressure testing material strength, etc., can solve the problem that the copper needle is easy to touch the bottom plane, difficult to take out, and difficult to take out the sealing ring and other issues, to achieve the effects of explosion-proof performance and stability guarantee, accurate side view data, and guaranteed fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

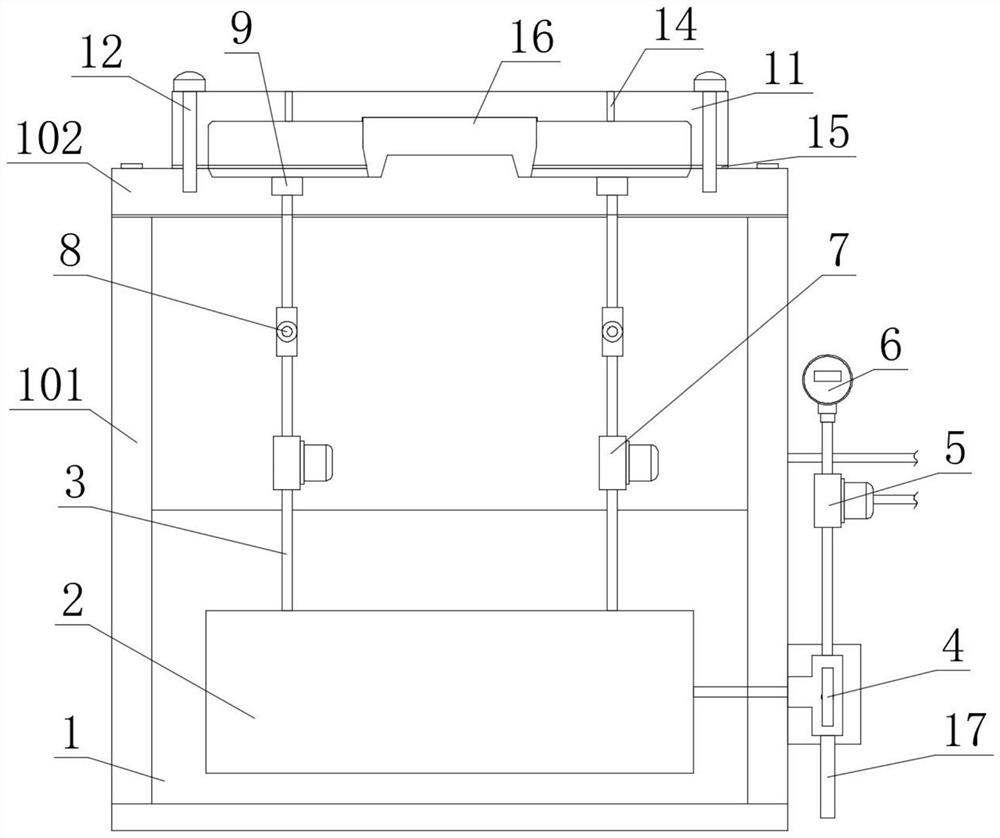

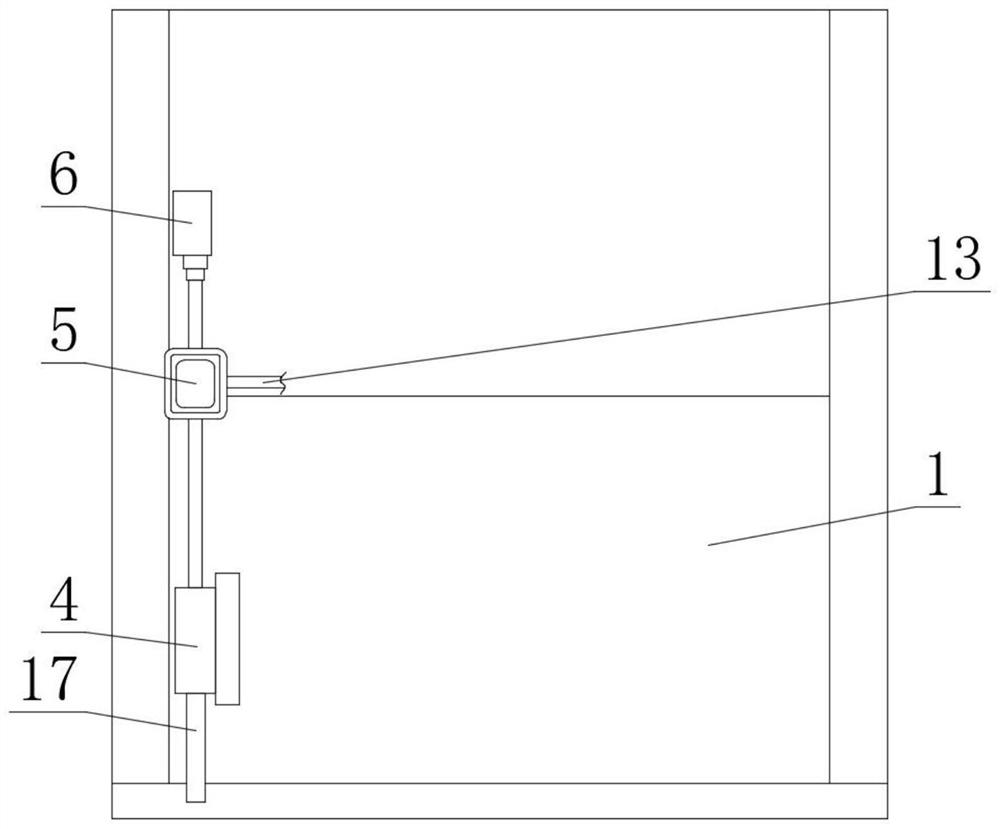

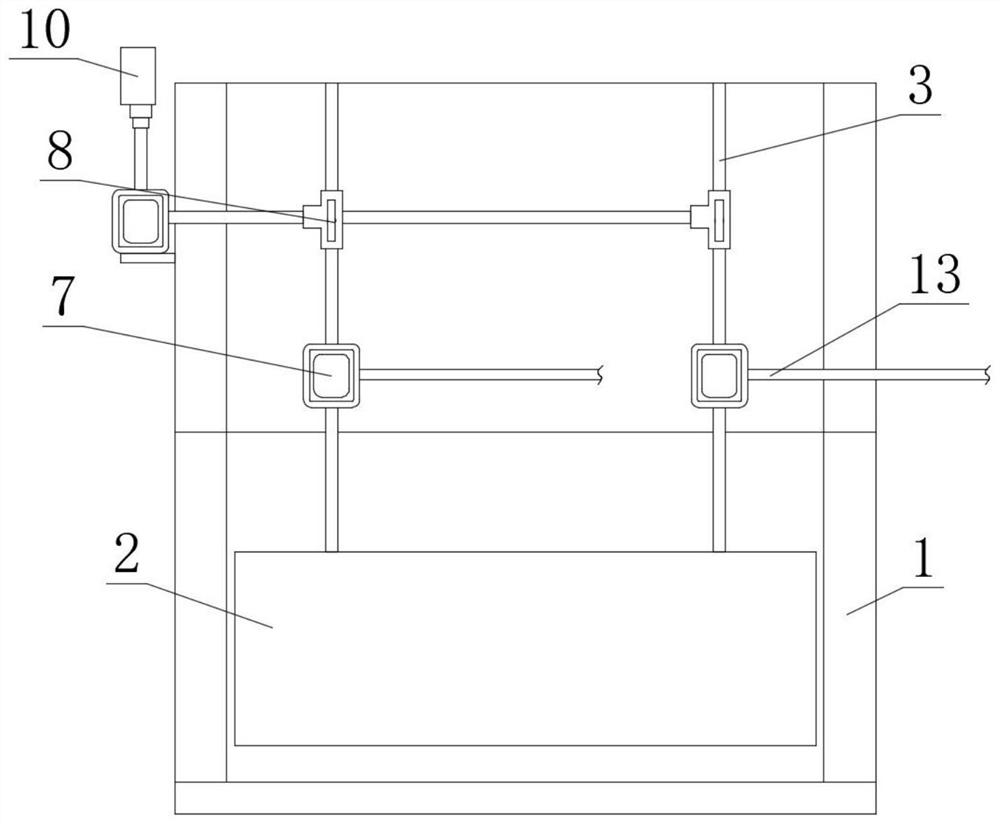

[0028] The following will clearly and completely describe the technical solutions in the embodiments of the present invention in conjunction with the accompanying drawings in the embodiments of the present invention;

[0029] see Figure 1~3 , in the present invention, sealing ring explosion-proof pressure detection device comprises detection mold main body 1, and the inside of detection mold main body 1 is provided with branch chamber 2, and the inside of detection mold main body 1 is equipped with several high-pressure pipelines 3, and the bottom of high-pressure pipeline 3 and The inside of the branch cavity 2 is connected, and the right side of the detection mold body 1 is equipped with a first high-pressure three-way pipe 4, and the left end of the first high-pressure three-way pipe 4 communicates with the inside of the branch cavity 2. A three-way air release valve 5 is installed on the top of the three-way air release valve 5, a pressure display gauge 6 is installed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com