Method for improving sound measurement precision of transformer

A measurement accuracy, transformer technology, applied in measurement devices, measurement of ultrasonic/sonic/infrasonic waves, instruments, etc., can solve problems such as external sound interference, and achieve the effect of suppressing external interference sound, easy to use, and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

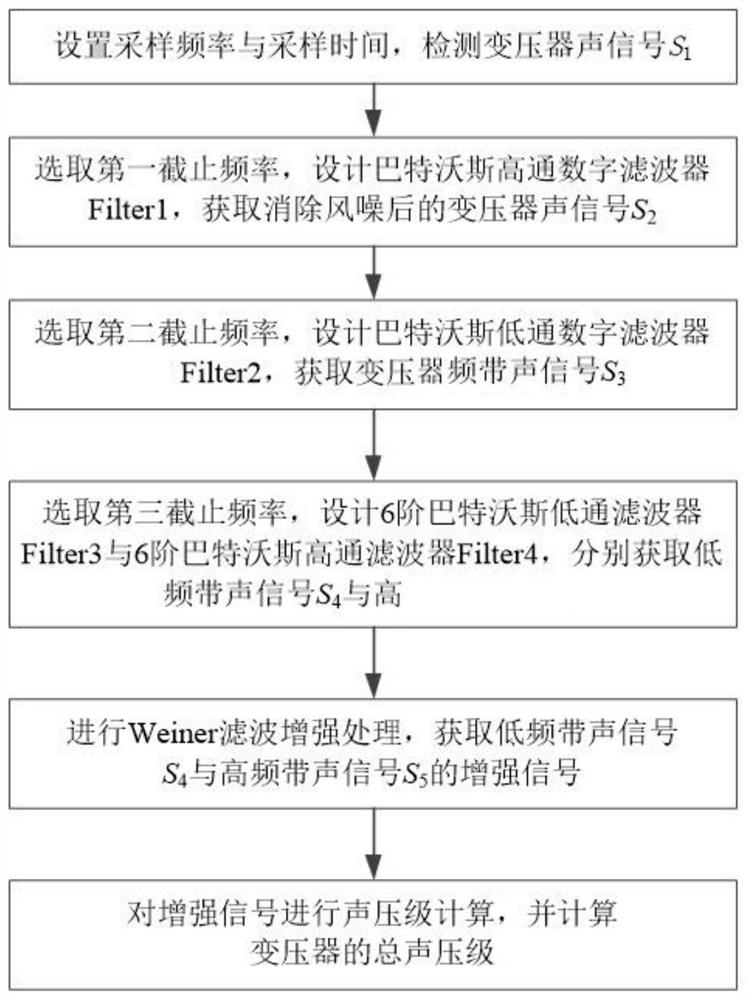

[0035] see figure 1 , the implementation steps of the method for improving transformer sound measurement accuracy in this embodiment include:

[0036] 1) Set the sampling frequency and sampling time to detect the transformer acoustic signal S 1 ;

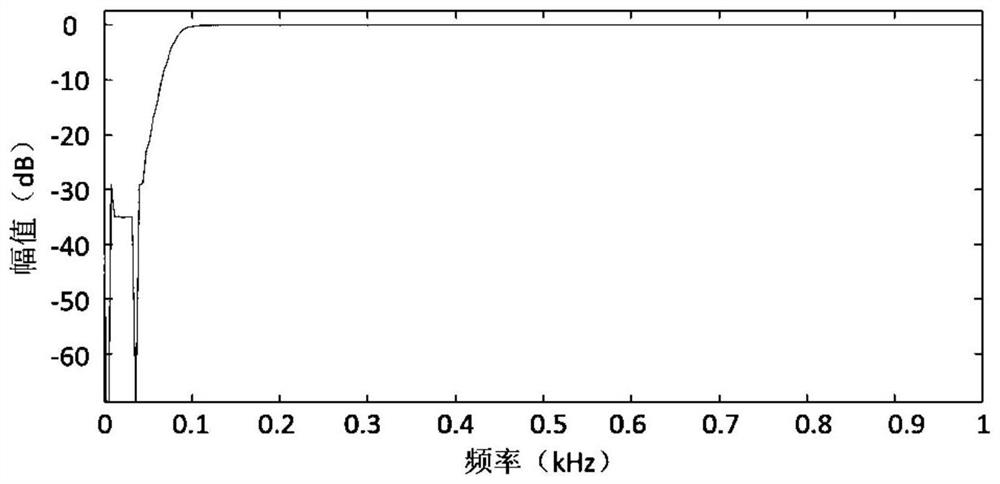

[0037] 2) Select the first cut-off frequency, design a 6-order Butterworth high-pass digital filter Filter1, and obtain the transformer acoustic signal S after eliminating wind noise 2 ;

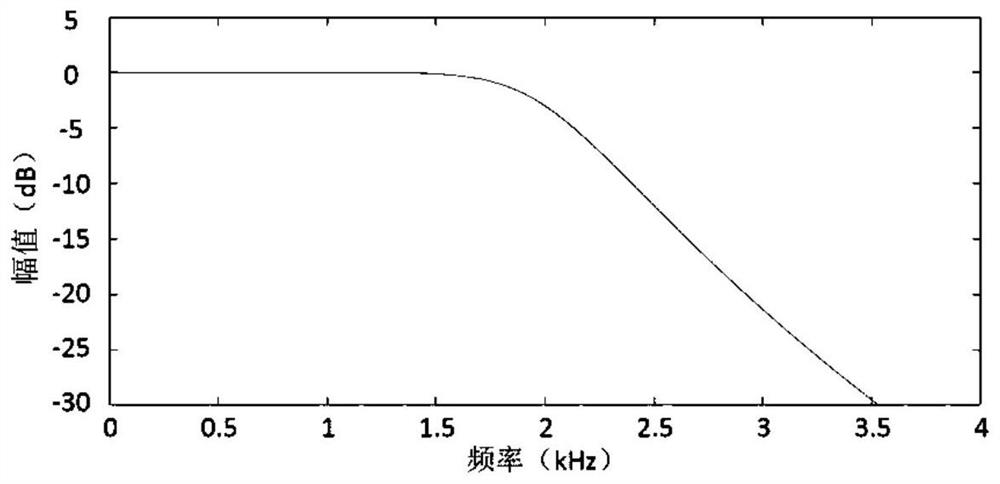

[0038] 3) Select the second cut-off frequency, design a 6th-order Butterworth low-pass digital filter Filter2, and obtain the transformer frequency band acoustic signal S 3 ;

[0039] 4) Select the third cut-off frequency, design the 6th-order Butterworth low-pass filter Filter3 and the 6th-order Butterworth high-pass filter Filter4 for the transformer frequency band acoustic signal S 3 process to obtain the low-frequency band acoustic signal S 4 with the high frequency band acoustic signal S 5 ;

[0040] 5) For the low frequency band acou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com