Rocket propellant liquid level optical measurement method based on double-radius solution

A rocket propellant and optical measurement technology, applied in the field of rocket propellant liquid level optical measurement, can solve problems such as the influence of liquid level inclination, and achieve the effect of improving the liquid level measurement accuracy, the method is simple and easy to implement, and the overall performance is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

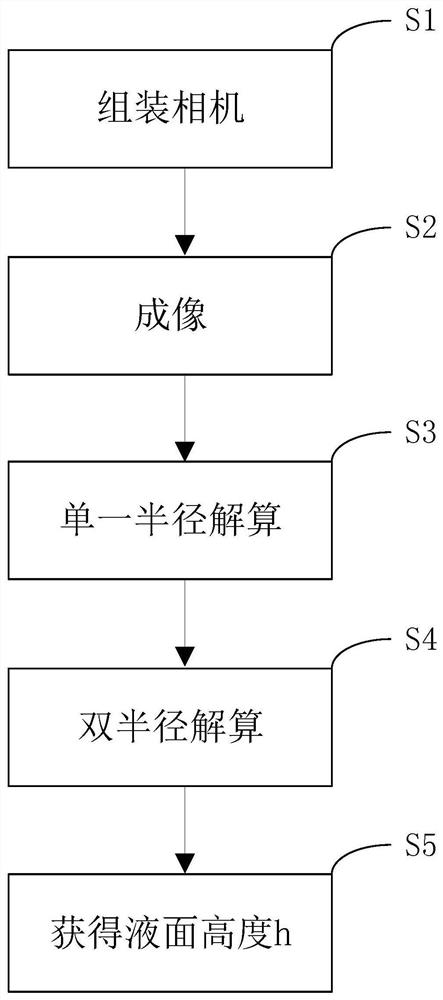

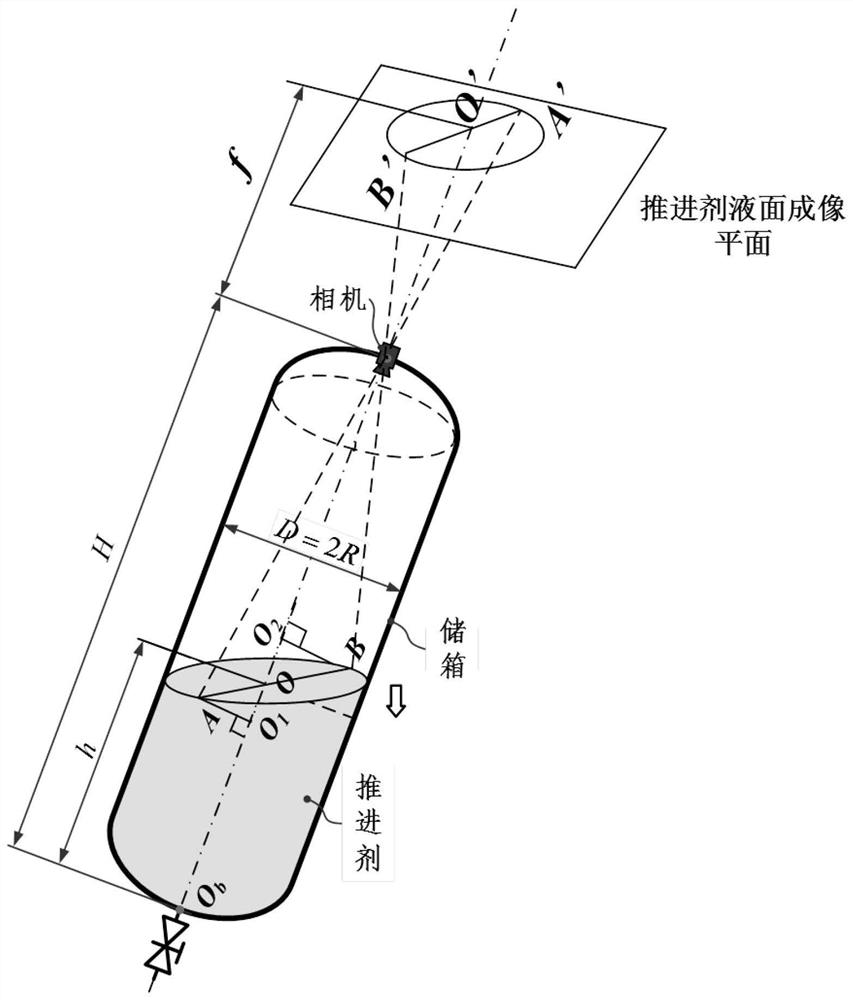

[0060] Such as Figure 2-4 As shown, a method for optical measurement of rocket propellant liquid level based on dual-radius solution includes the following steps:

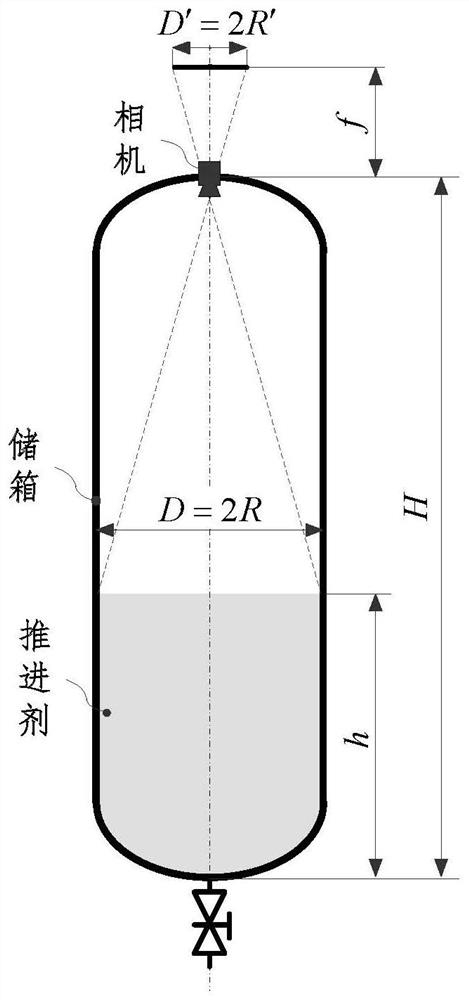

[0061] S1. Assemble the camera: install the camera on the top of the storage tank so that the visual axis of the camera coincides with the axis of the storage tank, and the storage tank is cylindrical;

[0062] S2. Imaging: The camera shoots the liquid surface of the rocket propellant to obtain an image of the liquid surface of the propellant;

[0063] S3. Single radius solution: select the radius O’A’ in the propellant liquid surface imaging, where the O’ point is the projection point of the storage tank axis on the propellant liquid surface imaging plane, and the length of O’A’ is R 1 ’, according to the imaging law, the propellant liquid level h is obtained as:

[0064]

[0065] Among them, H is the installation height of the camera from the bottom of the tank, f is the focal length of the camera lens, R i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com