Dryer for drying grape pollen

A dryer and drying technology, applied in the field of equipment, can solve the problems of reducing pollen activity, reducing the success rate, and few achievements, and achieving the effects of being beneficial to air flow control, preventing oxidation, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

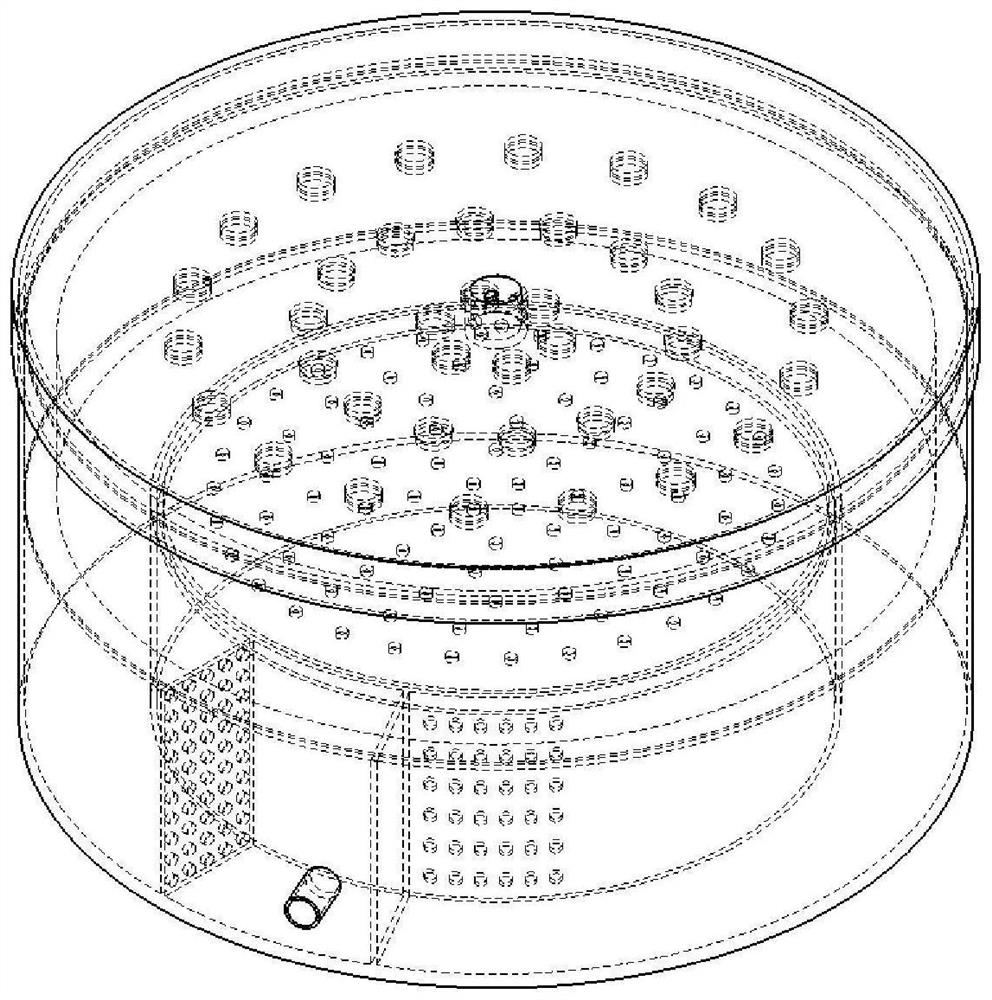

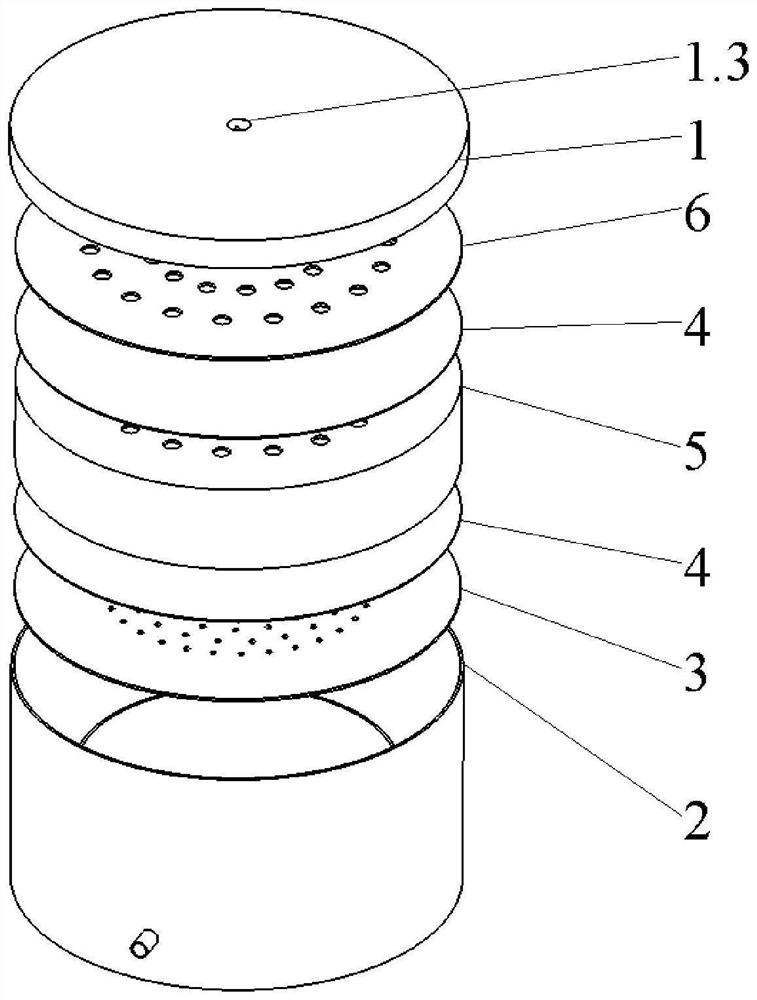

[0028] Attached below Figure 1-6 Concrete structure and application method of the present invention are further described with embodiment.

[0029] A drier for drying grape pollen comprises a cover body 1, a box body 2, a drying sieve 3, a pollen box 5, and a paperweight sieve 6 ( Figure 1-2 ); the box body 1 is fastened on the top of the box body 2. A drying screen 3, a filter paper 4, a pollen box 5, a filter paper 4 and a paperweight sieve 6 are sequentially placed in the wind box 2 from bottom to top.

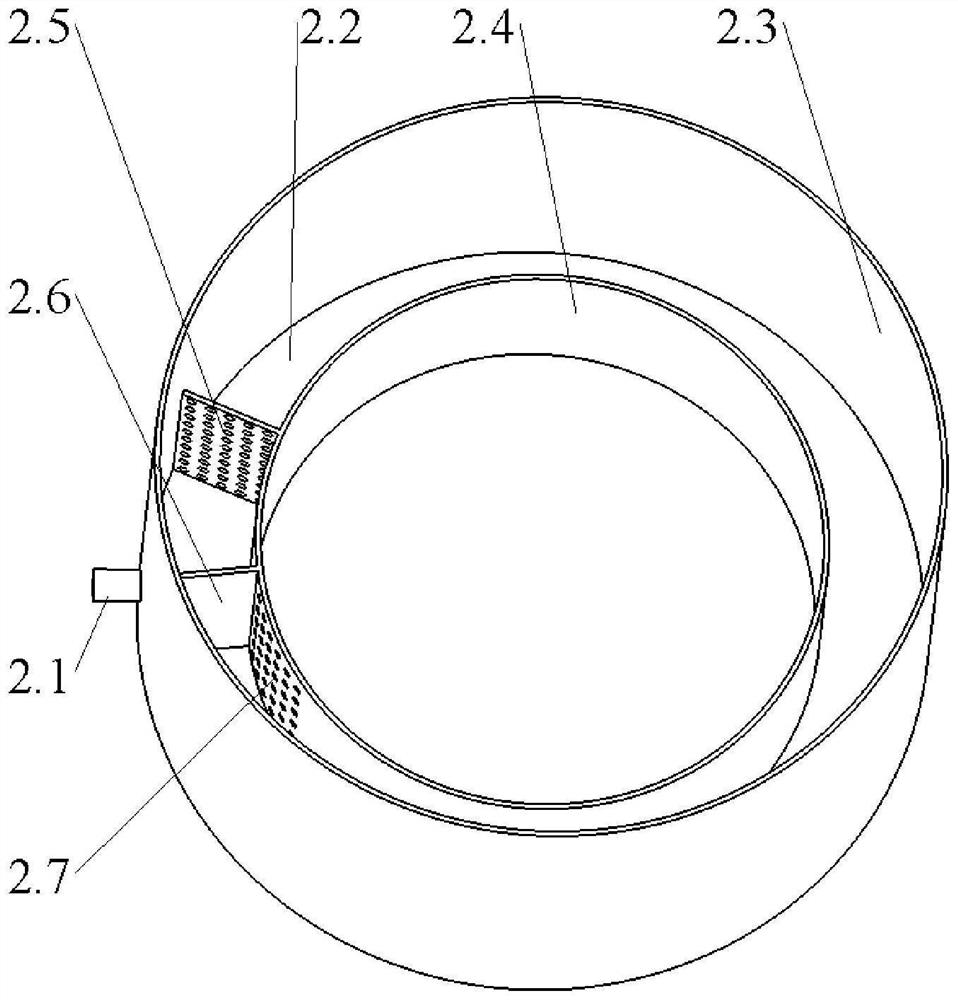

[0030] The lower end of the box body 2 is a box bottom 2.2, and the box bottom 2.2 is in the shape of a round cake; the outer wall 2.3 of a cylindrical shape is arranged on the periphery of the box bottom 2.2; the inner wall 2.3 is provided with a cylindrical inner wall 2.4, and the bottom of the inner wall 2.4 is arranged on the box bottom 2.2; The height of the inner wall 2.4 is lower than that of the outer wall 2.3.

[0031] An air inlet screen 2.5 and a windshield ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com