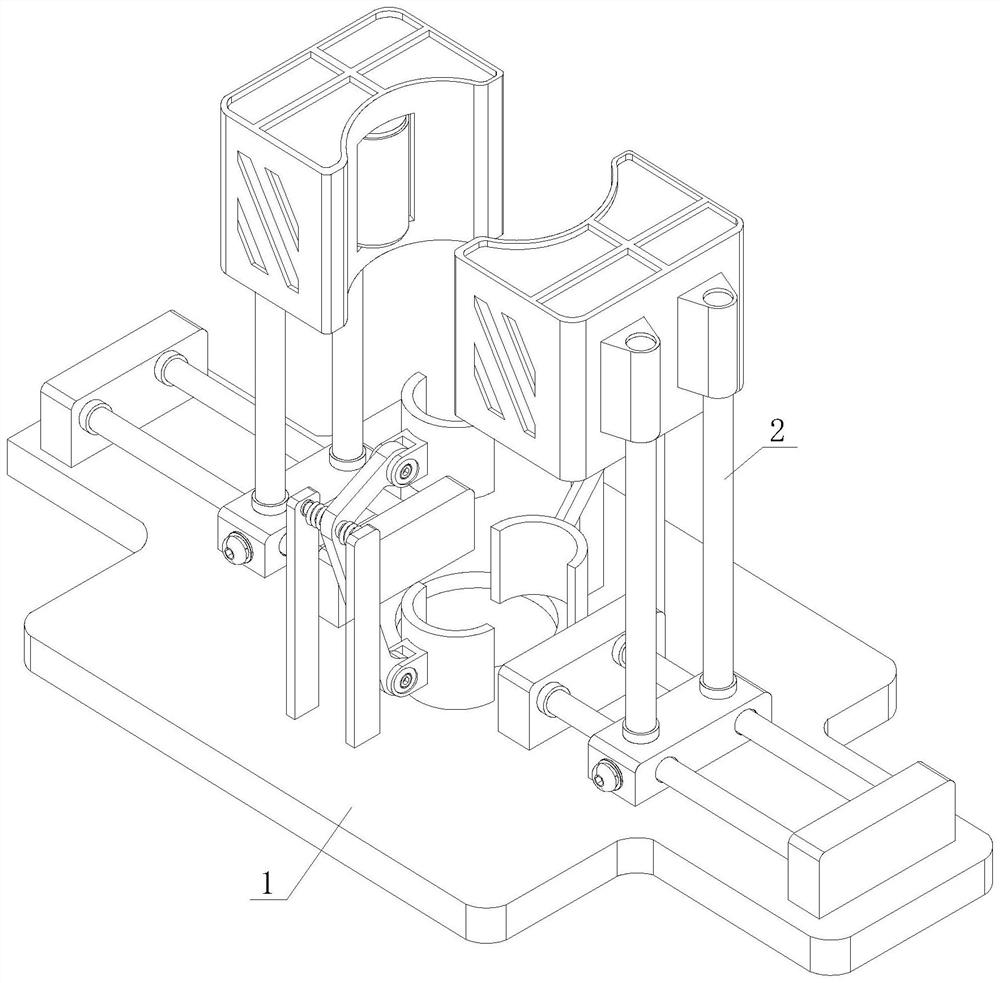

Drill rod lower pipe positioning device for mine exploration construction and implementation method of drill rod lower pipe positioning device

A technology of positioning device and drill pipe, applied in the direction of drill pipe, drill pipe, casing, etc., can solve the problem of inconvenient threaded connection, etc., and achieve the effect of convenient threaded connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

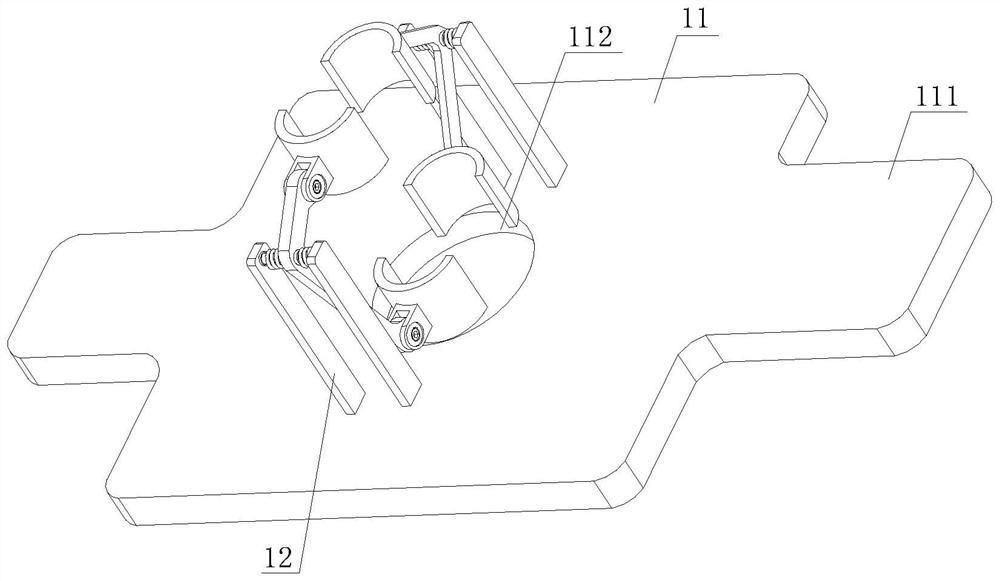

[0035] The present invention provides another technical solution: a method of implementing a drill pipe for a mining exploration construction drill pipe, including the following steps:

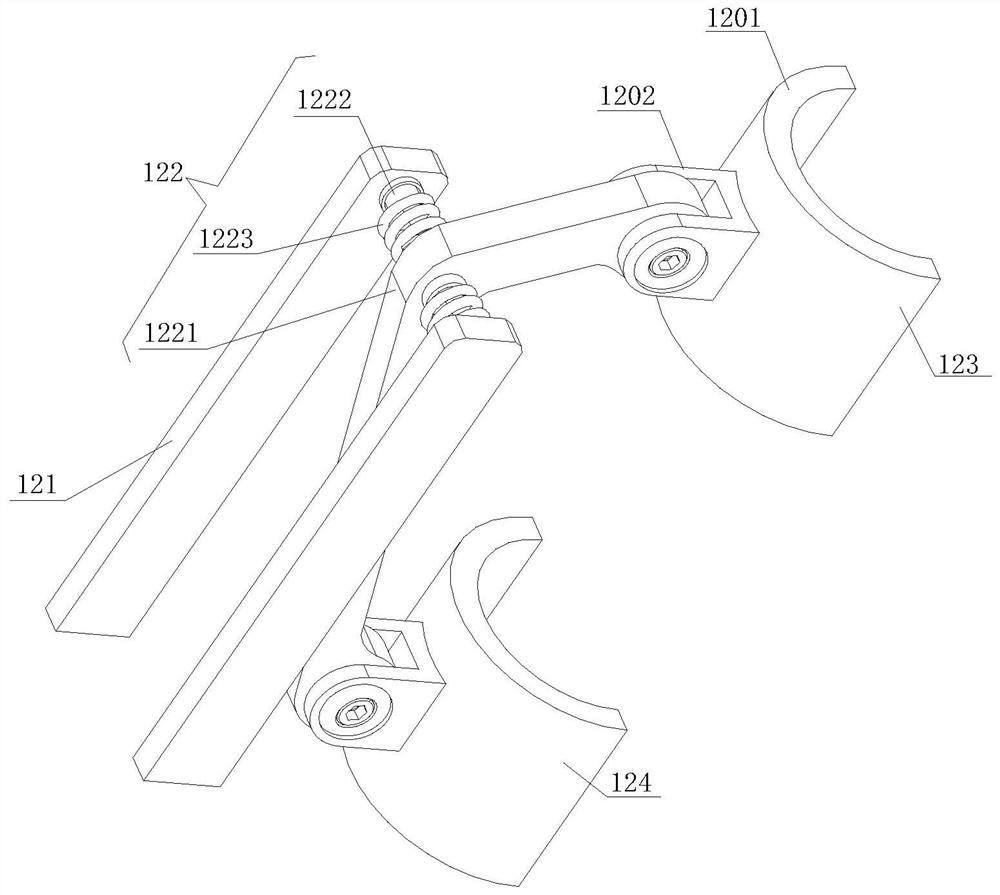

[0036] S01: The upper end of the probe that has been inserted into the underground is fixed between the lower positioning sheet 124;

[0037] S02: Probabilizing tube extrapolates the lower positioning sheet 124, the rod 1221 is rotated, and the upper end of the two groups of curved rods 1221 is collected inward, and the lower end to the detection tube is adjusted;

[0038] S03: Move the moving block 213 on the guide post 212, adjust the distance between the two sets of the auxiliary rotation mechanism 2 set, and the upper end of the detection tube is positioned;

[0039] S04: The start drive motor 2202 drives the rubber surface rotation shaft 2204 to rotate, and the rubber surface rotation shaft 2204 drives the tube to be connected to complete the thread connection between the probe.

[0040] Work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com