Machine-made silk floss refining method without hydrogen peroxide

A hydrogen peroxide and scouring technology, which is applied in the direction of improved hand fibers, textiles, papermaking, animal fibers, etc., can solve problems such as hidden safety hazards, and achieve the effects of improving safety, less chemical additives, and excellent compression and rebound properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

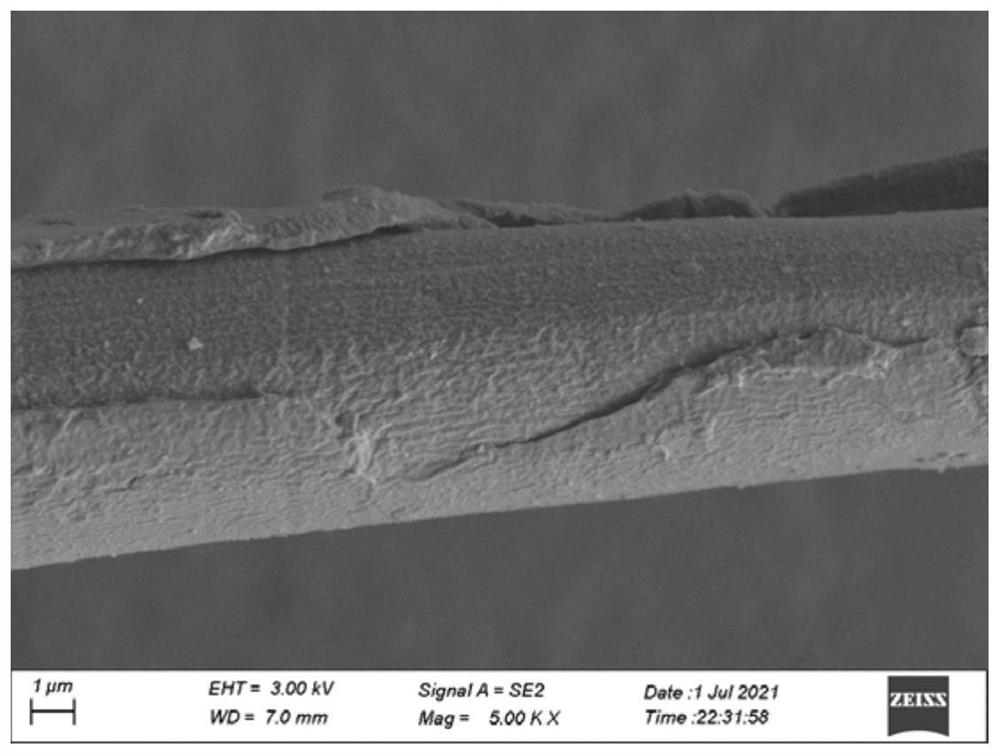

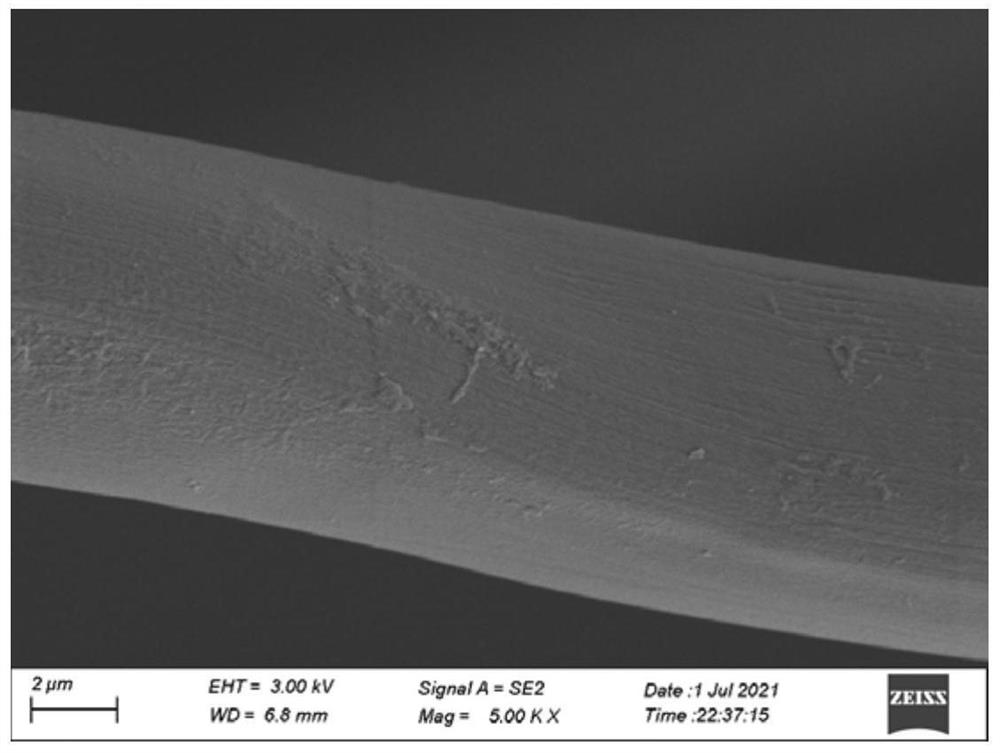

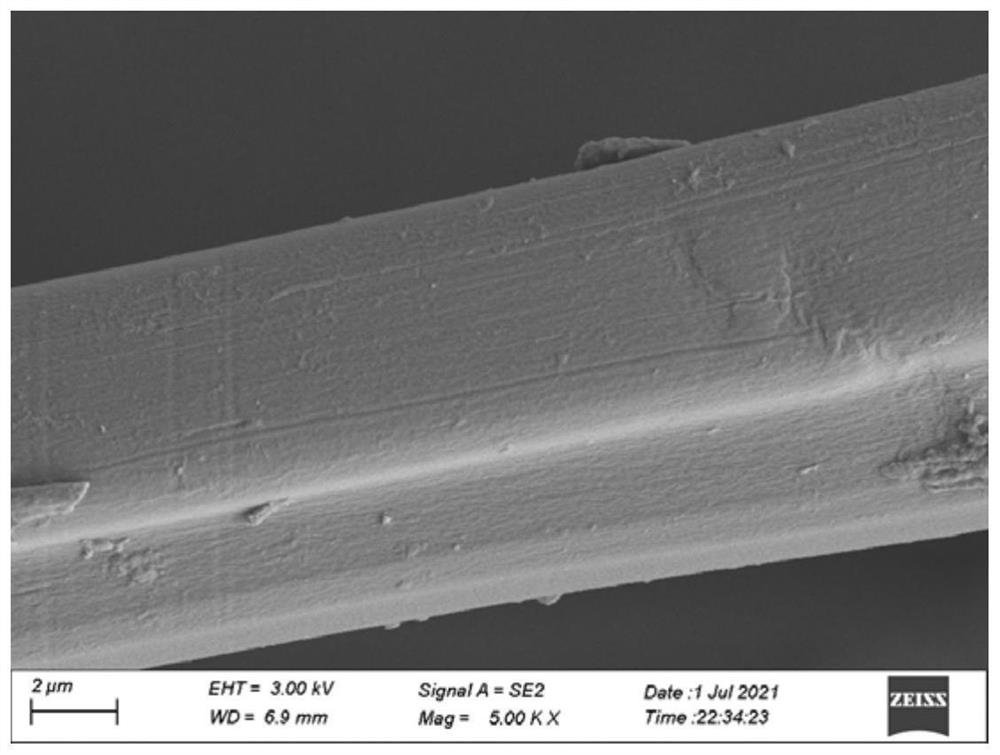

Image

Examples

Embodiment 1

[0023] A refined method of mechanism of a mechanism of no oxygen, including the following steps:

[0024] (1) Preparation of Jingjing Liquid: Weigh the calculated amount of sodium carbonate, dissolved in water, formulated aqueous solution of sodium carbonate is 0.70 g / L, add a quantity of surfactant JFC, so that the surfactant JFC in the solution The concentration was 0.05% to obtain a refinement.

[0025] (2) Silk silk

[0026] Heat the escaps to 100 ° C and insulation, press 1: 150 bath ratio to the mandies, and continuously heat treatment for 40 min.

[0027] (3) Cleaning

[0028] The silk monsoon was taken out from the refinery, and the first cleaning was carried out with water at a temperature of 80 ° C, and the second cleaning of water was 70 ° C, and finally washed with normal warm water until the pH of the washing liquid tend to neutralize. After drying, get refined silk.

[0029] (3) According to the weighing grant, the refinement rate is measured, and the reference sta...

Embodiment 2

[0037] A refined method of mechanism of a mechanism of no oxygen, including the following steps:

[0038] (1) Preparation of Jingjing Liquid: Weigh the calculated amount of sodium carbonate, dissolved in water, formulated aqueous solution of sodium carbonate is 1.0 g / L, add 0.02% fluorocarbon surfactant, mix well and uniformly .

[0039] (2) Silk silk

[0040] Heat the escaps to 98 ° C and insulation, press 1: 100 bath ratios to the silk, continuous heating treatment of 35 min.

[0041] (3) Cleaning

[0042] The silk monsoon was taken out from the refined liquid, and two cleaning was carried out with water at a temperature of 75 ° C, and finally was cleaned with normal warm water until the pH was neutral drying, and the refined silk was obtained.

[0043] (4) Test the whiteness of the silk stone in the RGB mode in Photoshop.

[0044] As a contrast, the commercially available products such as the same unit (Zhejiang Tongxiang Zhejiang Silkworm Home Textile Co., Ltd.) will be prov...

Embodiment 3

[0050] A refined method of mechanism of a mechanism of no oxygen, including the following steps:

[0051] (1) Preparation of Jingjing Liquid: Weigh the calculated amount of sodium carbonate, soluble in water, formulated aqueous solution of sodium carbonate to 1.50 g / L, add 0.1% surfactant JFC, and mix well after mixing.

[0052] (2) Silk silk

[0053] Heat the escaps to 95 ° C and heat premium, and put the silk tabs ratio of 1:50, continuous heating treatment for 30 min.

[0054] (3) Cleaning

[0055] The silk monsoon was taken out from the refined liquid, and the water was cleaned with water at a temperature of 80 ° C, and then washed with normal warm water to be neutral.

[0056] (4) Determination of refinement rate according to the weighing grant, refer to standard GB / T 24252-2019 "Silk is" Appendix D "Filler Compressed Back Elastic Test Method", test silk-moving compression backlays.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com