Solid rare earth hydrogen storage alloy with low hysteresis and high pulverization resistance and its preparation and application

A hydrogen storage alloy, low hysteresis technology, applied in chemical instruments and methods, hydrogen, inorganic chemistry, etc., can solve the problems of increasing the hysteresis of hydrogen absorption and desorption of hydrogen storage alloys and receiving poisoning, shortening the service life of hydrogen storage alloys, etc. Achieve the effects of reducing structural differences, improving anti-powdering ability, and reducing hysteresis of hydrogen absorption and desorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

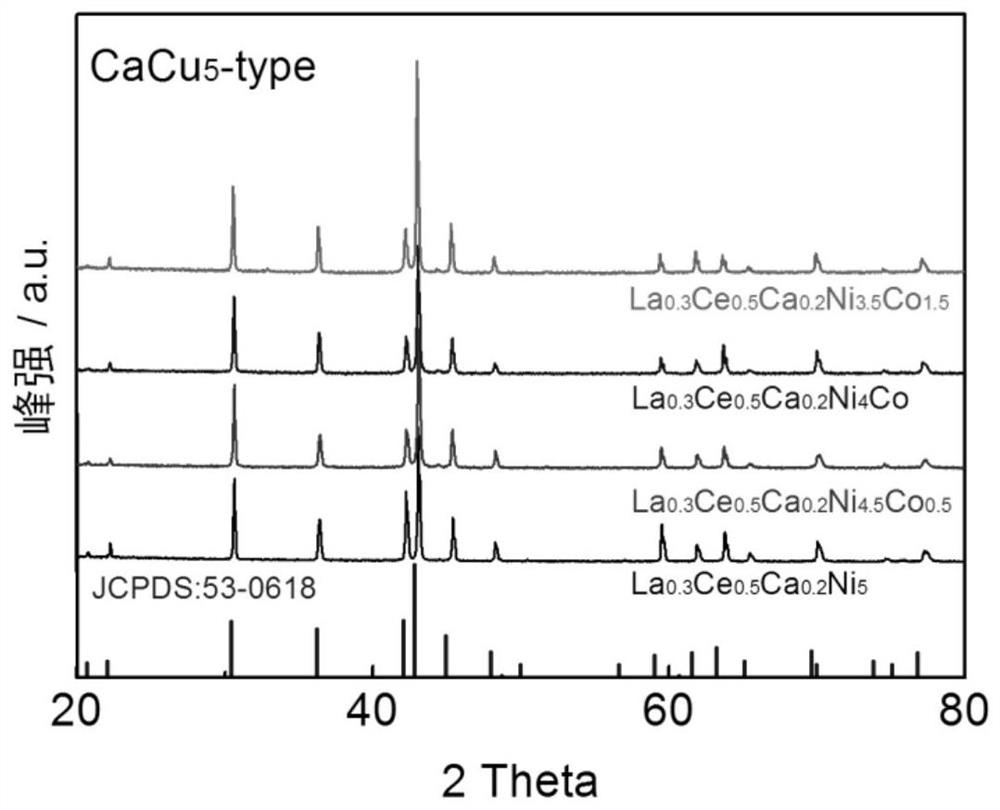

Embodiment 1

[0046] Alloy chemical composition is La 0.3 Ce 0.5 Ca 0.2 Ni 4.5 co 0.5 , Calculate the addition amount of La, Ce, Ca, Ni, Co elemental raw materials according to the rare earth hydrogen storage alloy. Among them, the purity of the used La, Ce, Ca, and Ni raw materials are all above 99%. After the above raw materials are cleaned, they are weighed according to the calculated addition amount. Put the weighed metal raw materials in the water-cooled copper crucible of the magnetic levitation induction levitation melting furnace. After evacuating to a vacuum of 0.3 Ce 0.5 Ca 0.2 Ni 4.5 co 0.5 Rare earth hydrogen storage alloy.

Embodiment 2

[0048] Alloy chemical composition is La 0.3 Ce 0.5 Ca 0.2 Ni 4 For Co, the addition amount of La, Ce, Ca, Ni, and Co elemental raw materials was calculated according to the rare earth hydrogen storage alloy. Among them, the purity of the used La, Ce, Ca, and Ni raw materials are all above 99%. After the above raw materials are cleaned, they are weighed according to the calculated addition amount. Put the weighed metal raw materials in the water-cooled copper crucible of the magnetic levitation induction levitation melting furnace. After evacuating to a vacuum of 0.3 Ce 0.5 Ca 0.2 Ni 4 Co rare earth hydrogen storage alloy.

Embodiment 3

[0050] Alloy chemical composition is La 0.3 Ce 0.5 Ca 0.2 Ni 3.5 co 1.5 , Calculate the addition amount of La, Ce, Ca, Ni, Co elemental raw materials according to the rare earth hydrogen storage alloy. Among them, the purity of the used La, Ce, Ca, and Ni raw materials are all above 99%. After the above raw materials are cleaned, they are weighed according to the calculated addition amount. Put the weighed metal raw materials in the water-cooled copper crucible of the magnetic levitation induction levitation melting furnace. After evacuating to a vacuum of 0.3 Ce 0.5 Ca 0.2 Ni 3.5 co 1.5 Rare earth hydrogen storage alloy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com