Blank off-line grade judgment device and method

An embryonic, offline technology, applied in the field of tire manufacturing, can solve the problems of larger laser spot than defects, unrealistic installation and testing equipment, different light source directions, etc., so as to reduce vulcanization and inspection work, reduce the risk of entering the market, and determine grades. The effect of high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The device and method of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

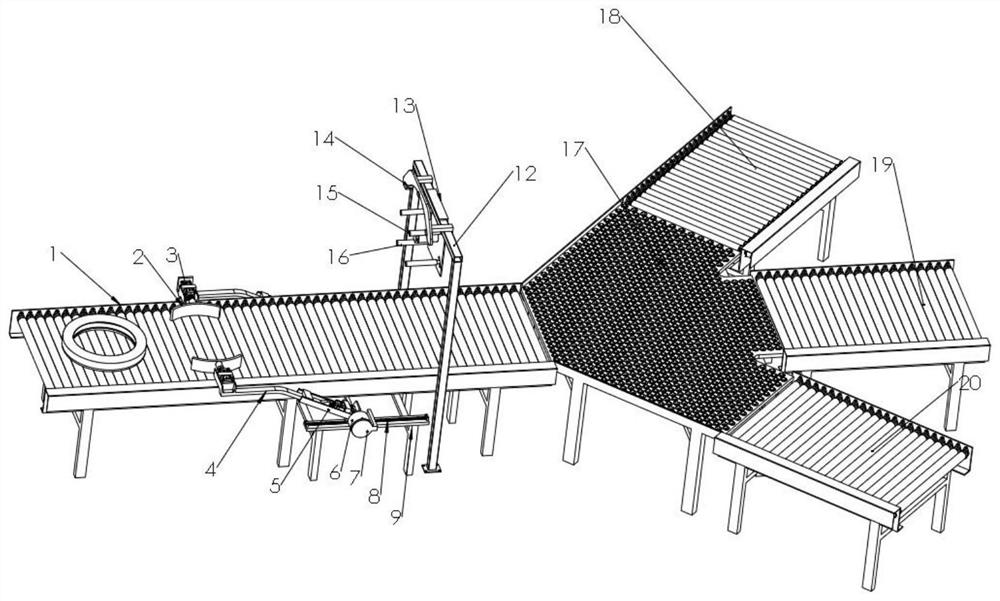

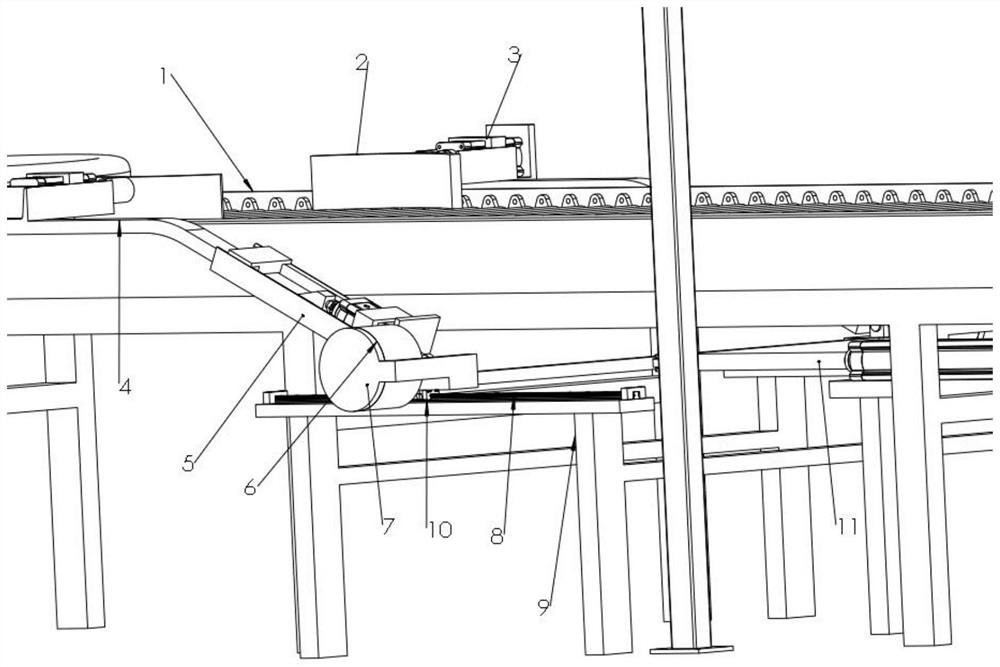

[0025] like figure 1 , figure 2 As shown, an off-line embryo classification device includes a main control module, a logistics conveying roller table 1, an embryo holding and clamping mechanism, an embryo supporting detection mechanism, and an embryo diverting mechanism.

[0026] The main control module is connected to the logistics conveying roller table 1, the embryo holding and clamping mechanism, the embryo support detection mechanism and the embryo diversion mechanism; the logistics conveying roller table 1 is connected to the embryo diversion mechanism, and the The tire embryo support detection mechanism is arranged on the front side of the connection between the logistics conveying roller table 1 and the embryo embryo diversion mechanism, and is used to detect the embryo embryo. The embryo embryo holding and clamping me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com